Image Credit: Quality First Basement Systems

A hundred years ago, homes had cellars, not basements. The typical cellar has stone-and-mortar walls and a dirt floor. Such a cellar is cool and humid, so it’s the perfect place to store carrots and potatoes. If a cellar floor got wet during the spring thaw, no one cared. After all, it’s not as if anyone was playing ping pong down there.

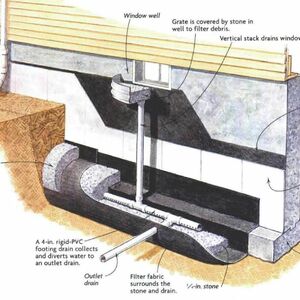

These days, however, most homeowners expect basements to stay dry. During the 1930s and 1940s, as basements gradually replaced cellars, construction specifications for residential foundations improved. Poured concrete walls replaced stone walls; concrete slabs replaced dirt floors. Some builders even included footing drains.

But the results of these efforts were uneven. Millions of Americans are still living in homes with damp basements.

New construction tips

This article will focus on ways to fix a damp basement so that it’s dry enough to use as indoor living space. Before tackling that topic, though, I’ll briefly outline the steps used during a new construction project to keep the basement dry.

Remember: fixing a wet basement can cost tens of thousands of dollars. It will never be easier to get the details right than when a home is first built; spending a few hundred extra dollars now can save thousands later.

If you are building a new home, and you want a dry basement, you should specify:

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

40 Comments

Nice summary

The way I teach this is the following. Want a dry foundation? Design your building and design the excavation. Create a tent roof like the building roof, dig the excavation, and put the tent roof over the excavation. Then wait. Maybe a year, maybe more. After every heavy rain go back to the hole and see if the hole is dry. If, after a long wait the hole remains dry then build your building and put it in the hole. If your hole gets wet, well, why would anyone want to put a perfectly good building in a wet hole? This is the design project I give to students: design a dry hole in the ground. Not easy.

Holes in crawlspace walls

Perfect timing. I've started demolishing my settled patio, and regrading where it was. I have a small 4x16 all-concrete crawlspace connected to my basement and a little bit of water trickles in during heavy rain, through these mysterious holes at the bottoms of the walls. I haven't been able to find anything about them on the internet, so I think some misguided previous owner may have drilled them in an attempt to let the accumulated water out? I hope that once I'm done regrading, the ground will remain dry enough that the holes will no longer leak water into the crawlspace. Should I then plug them up? Do they serve some other purpose I'm not aware of? The crawlspace has the same wood form imprints as the rest of the foundation so I'm quite sure it's not CMU. The home is from 1950 in Portland OR.

Response to Nick Welch

Nick,

It's hard to know exactly what the holes are for. You haven't described the shape or size of the holes, or how many there are. But ultimately it doesn't really matter, because there is no reason to have holes in your crawl space walls. Feel free to plug the holes with concrete, mortar, or canned spray foam.

Don't connect the outside to the inside

Good article. I am a commercial contractor and live in 100 plus year old community. I have helped several neighbors fix their leaking basements just by directing the downspout water away from the house and cleaning/repairing gutters. Almost always solves the issue in our area.

I am currently building a "pretty good" house and was very surprised when the residential foundation contractor started to connect the outside drain tile to the interior drain tile using pipes run under the footing. When I asked him why, he said "we always do that". My comment back was roughly why did I spend all that money on waterproofing and drainage board to keep the water out when you are installing pipe to let it in? Followed by "Not on my house!" and had them pull the connecting pipes out. The county inspector asked where those connecting pipes were and after I explained that I didn't want them and was daylighting the exterior drain, he agreed to leave them out, but I don't think he was happy. In 20 plus years of commercial construction I have never connected the exterior drain tile to the interior drain tile. The idea is very strange.

I have learned while building my house that residential contractors have some very different construction techniques than commercial. Like the amazing conversation I had with the excavation contractor as he explained why it's better not to tamp the backfill to 95% or, basically, at all, even under slabs. Another "Not on my house!" moment. There have been others and I'm sure there will be more.

Andrew

Response to Andrew Marani

Andrew,

I don't agree with the logic you use to argue that there should be no drainage pipe across the footings. If the water table rises to the level of the bottom of your footing drains, you are going to have wet soil under your basement slab, with or without a pipe connecting the interior with the exterior. Underground water moves sideways, with or without the pipe. The purpose of the pipe is to help drain the water quickly.

What you want is plenty of free-draining material under the slab to encourage any water to move to the footing drain. That's what the pipe is for. Since you have rigid foam and polyethylene above the crushed stone, the presence of liquid water at the crushed stone layer will not make your slab damp.

Many builders install a continuous layer of crushed stone that underlies their footings as well as the slab. This is the standard method for so-called Permanent Wood Foundations, and it is a method that is routinely used for slabs on grade and frost-protected shallow foundations as well. If you are building your foundation on a continuous layer of crushed stone, you will have opportunities for water to move sideways through this layer. What keeps the layer dry is your perforated pipe, connected to a drain.

Omitting the pipe through the footing is a placebo measure. It doesn't prevent water from moving sideways under your slab; it just reduces your drainage opportunities.

I am attaching two photos showing sites where the footings are installed on a continuous layer of crushed stone.

.

Delta-FL - Good, .DRIcore - not so good

When DRIcore first came out I thought it was a great idea and used it on several basement projects until the problems started - some big, some small. Panel edges swelled and the required 1/4 in. perimeter space was not enough to prevent buckling. My guess is that because the dimple mat backing on each DRIcore panel doesn't seal to the adjacent 4 panels, there can be enough moisture absorbed by the wood over time for irreversible expansion to occur.

Delta-FL is a separate sheet that gets taped at joints and sealed at the perimeter. No problems in basements with Delta or other full-coverage dimple mat systems.

Mike, were you using the Dricore Subfloor (with the plastic dimples) back then, or the Dricore "Subfloor R+" with the XPS (foam) squares? I'm wondering if both products would have the sealing problem you experienced.

Response to Mike Guertin

Mike,

Thanks very much for sharing your job-site experience; I have edited my article to reflect your comments.

This is a good opportunity to warn remodeling contractors that any contractor who takes on a basement remodeling project is taking on a significant amount of liability. If you are an experienced professional with good insurance coverage, such jobs may make sense, and may even be highly profitable. However, there are more uncertainties with below-grade work than above-grade work -- a fact that contractors should keep in mind when setting their prices.

Martin,

I don't think we are

Martin,

I don't think we are gong to agree on connecting the outside/inside. Water does move horizontally, but we install drainage board against the exterior waterproofing to reduce hydraulic pressure against the waterproofing. This creates a nearly perfect vertical drain to allow surface and below surface rain water down to the exterior footing drain and from there into the house.

Daylighting the exterior drain interrupts the horizontal movement of water so it does not flow under the footing. Most houses in our area are built with basements and the footings are set on virgin soil, with no drainage under the footing. The water will take the easiest path, which would be the exterior drain tile to daylight.

Where there is no possibility of daylighting the exterior drain tile, the connection you recommend allows the sump pump to remove the excess water, so I see the usefulness in that situation. However, my personal opinion is that many residential builders use the connection as a cheaper (and less effective) solution. It cost more to run a 50' or 100' trench to daylight the exterior drain tile. The sump pump works fine most of the time, until there is a large storm dumping a lot of rain and causing a power outage.

Andrew

Response to Andrew Marani

Andrew,

I certainly agree with you that draining to daylight is far more dependable, and therefore preferred, to draining to a sump pump.

That is a separate issue, however, from the question we are discussing: whether it makes sense to install a drain pipe through the footing to connect the crushed stone on the exterior side of the footing with the crushed stone on the interior side of the footing.

Clearly, you remain unconvinced of my recommendation, so I guess we'll just have to agree to disagree.

Issues with dimple panels

I believe the recommendation was to use a dimple panel on the outside of the foundation to provide drainage or secondarily crushed stone. I have issues with the dimple panels. I am finding that when dirt is backfilled around the foundation and panels, the dirt grabs the panels as it settles and pulls the panels downward. In many cases, the downward forces is enough to pulle the panels out of the termination bars along the top of the panels. That leaves an opening for water to get between the panels and foundaiton.

Some will likely say that the panels were installed properly. In one case with which I am very familiar, the installation instructions were followed exactly, including use of the proper fasteners, spacing of fasteners, terminating the panels, etc. Again, as the soil settled, it grabbed on the panels and pulled them downward. I have attached a couple of photos.

Response to Matt Klein

Matt,

I don't have a lot of experience installing dimple panels, so I can't comment on whether the problem you describe is common. But even if a dimple panel is displaced downward one or two inches, as shown in the photo, I can't imagine that it would matter very much. The dimple panel would still be covering 99% of the area that was intended, and it would still work.

Perforated drain pipe replacement?

It seems that perforated drain pipe covered in gravel is a standard advice. I would suggest a (possibly) better alternative -- stripdrains, like the one made by Terrafix. The main difference is the amount of dirt one have to excavate and amount of gravel one needs to fill the trench (stripdrain does not need the gravel). 8x8 inch trench along 150 feet long basement wall means 67 cu.f of dirt (@78 lb/cu.f = 5200 lbs) and the same amount of gravel( 5000 lbs).

testing wet walls with polyethylene

I was confused about the purpose of testing the wet walls with polyethylene (thought it might be for newly poured concrete), and found this:

http://www.cmhc.ca/en/inpr/su/regrgu/regrgu_007.cfm

A Simple Test for Capillary Moisture Problems

To find out if a foundation floor or wall is wicking moisture into the house, try this test: attach a square of polyethylene film (300 x 300 mm) to a dry section of wall or floor and seal the edges with tape. Leave it for a day or two. If moisture appears on the underside of the sheet, it is migrating through the concrete. This test is not exact but can usually reveal a problem if it exists.

This test is worthwhile even if there are no reported and no visible signs of moisture before undertaking a basement finishing project. Moisture may have been evaporating through the floor and walls without obvious signs. If undetected, this may become a serious problem after the surfaces have been covered with new finishes that might trap the moisture and cause it to accumulate to the point where it becomes a problem.

Response to Erich Riesenberg

Erich,

If you read the article on this page -- the page where you posted your comment -- you'll notice that I recommend the same test as the one you refer to. My advice can be found under the heading, "How to tell if your basement wall is too wet to insulate."

Moisture Stop

Yes, I saw you recommended the test, I just wasn't sure why, so went looking before asking the question, and posted the answer I found.

I have a dry basement and plan to insulate it. I came across a Rustoleum product called Moisture Stop which claims to prevent water (and radon). The active ingredient is Sodium Silicate. (related product called Fortifying Sealer)

Does it seem like a reasonable step to take as a precaution? I think it can also be coated with a waterproof paint. Sold at Menards and HD.

Can't post a link due to the spam filter, attached the MSDS.

Thanks and happy holiday. Strangely warm in midwest, mid-50s.

Response to Erich Riesenberg

Erich,

Once again, I addressed your question in the article. I wrote, "At this point, it makes sense to try a few measures which, although questionable, are relatively inexpensive and therefore worth trying. I’m talking about installing a so-called waterproof coating on the interior of your concrete walls. Brand names for these products include Thoroseal, UGL Drylok, and Xypex.

"There’s no doubt that these products work, and they can definitely turn a damp basement wall into a dry one. They just can’t solve every problem. If the hydrostatic pressure on the exterior side of your basement wall is high enough, none of these products will be able to resist the pressure of the entering water. The bottom line is, these products are worth a try."

Once again, I did see the

Once again, I did see the generic reference to waterproofing products.

I will depend on the sales literature.

Happy holiday!

Quesion

Howdy. I've got a question for you, cause i'm aJ ohnny-come-lately: has anybody used liquid rubber for waterproofing basement walls, e.g. these waterproofing products http://liquidrubber.ca/ ?

Response to Alex Larson

Alex,

As I noted in the article, several coating products are sold for use on the interior side of basement walls. These products include Thoroseal, UGL Drylok, and Xypex.

The product you mention is a roofing product. I see no mention on the manufacturer's web site of the use of this product on basement walls. For that reason alone, I wouldn't use it.

dealing with minor wall wetness in finished basement

I'm helping a friend deal with some wet block walls in a finished, carpeted basement of a 35-year old house built on a steep hillside in Virginia. We've had an extremely wet spring, but even with this moisture, the wet-ness is limited to the bottom few inches of wall in most places, except one corner where it extends up about 4 feet. There has been no standing water on the floor.

The existing wall assembly is drywall nailed to 1x2 pine furring strips that are nailed into block walls. There is 3/4" EPS foam between the furring strips. The bottom few inches of the furring strips are starting to rot, and there is some fuzzy mold growth. Despite no major water infiltration, it is clear that wall wetness has been a chronic issue as the wood in wet areas is showing signs of rot.

We are going to try some of the exterior approaches to this such as grading, downspout redirecting, and maybe a French drain uphill from the house a little way. The interior feels more uncertain, especially since they are very concerned about mold growth potential.

On the inside what we have done so far is to remove remove the drywall 4' up the wall to the point where the block is all dry. We have also removed all the foam and furring strips to that point and treated it with vinegar and hydrogen peroxide to kill mold. I'm wondering a few things:

1. is it necessary to let the block dry before we cover it up again with anything (and will the block even dry if it is against damp soil?)

2. is there any reason not to paint drylok on the block? (One website I read claimed that Drylok can make mold worse as it is a food source for mold)

3. Instead of just removing the bottom 4 feet where it is wet, should I go ahead and remove all the drywall, foam and nailers floor to ceiling on the exterior walls and do the preferred method of continuous foam rather than the foam between nailers? This seems like overkill, but it also seems easier than trying to switch wall assemblies halfway up.

4. The floor has carpet directly over concrete. I assume it is advisable to remove carpet in this situation, generally speaking. Is there any way to tell if carpet is moldy other than pulling it up and scraping the carpet pad off the concrete to which it is glued?

Thanks for any advice on this!

Response to Timothy Godshall

Timothy,

You call this wetness "minor," but if you have "fuzzy mold growth" and "furring strips that are starting to rot," the wetness isn't minor. This type of basement should never have been finished without first doing a better job of dealing with the moisture entry issues.

What should you do now? It's all about the budget. My article describes all the options.

Open it up and don't install any finishes until the block wall is completely dry.

Fixing this problem may be expensive. The options may be (a) spend the money required, or (b) remove the finishes and call it an unfinished basement.

Martin: I live in a 100+ year old house outside Philly. The house has no footings and is stone stacked wall. As you can imagine I have moisture issues.

Since a dig out and pouring footers would run me about $60 to $100k, it would be expensive and not really worth while since we aren’t the type that will take advantage of the extra space.

I’m considering the regrading the back of the house and adding a concrete patio with some additional drainage to potentially eliminate the water seeping in from the side of the house that isn’t regraded and most likely the cause of all the water issues due to the pitch from the 4 lane min-highway onto my property. However, that may not eliminate my basement floor issue.

The floor was a dirt floor and some time ago, don’t know when, someone poured concrete. From the looks of it, there doesn’t seem to be plastic under slab based on some holes in the concrete. Additionally the concrete seems to be somewhat thin. I don’t mind making the space a tall crawl space (approximately 1500 sq. ft.). Are there any better options since getting aggregate and concrete in the basement would be a challenge?

Leonard,

Your basement is typical for an old house, and you're on the right track concerning solutions. On the exterior, you should (as you have already planned) correct the grading where possible. If you install a new patio, make sure that the patio slopes away from the house. If there are no gutters at the eaves, it may make sense to install roof gutters and to direct the roof water to a location far from the foundation.

Other than that, you just have a typical old basement. Install a sump and a sump pump if necessary, and use a stand-alone dehumidifier if you want to. That's the normal state of affairs for an old house.

Thank you!

Creating a combined French drain and active radon mitigation system is intriguing. Cross referencing this article to your "Radon mitigation with interior perimeter drains?" in Fine Home Building, it seems like the important details are to seal the French drain with concrete (don't leave the crushed stones exposed) and make sure the sump pump lid is airtight.

I have water appearing along the edge of my basement after big rainfalls. I'm in Canada near Toronto with a concrete foundation that's 100 years old so there's not going to be any insulation or vapour barrier under the slab. I'm focusing on stormwater management right now.

A have a few questions:

1. Will the aforementioned French drain & active radon mitigation help solve perimeter water issue? Will this depressurize the slab in the same way that radon mitigation alone would do?

2. I want to install skirt insulation that will double as an in-ground gutter. This will also reduce the chance of freeze-thaw damage to the foundation and allow me to install interior insulation.

4. Since the crushed stone will be covered with concrete, can I then proceed with the "how to insulate your basement" advice by installing 2" EPS, a stud wall with Rockwool batts, drywall, and latex paint?

Andrew,

You have double posted your question. Some of your questions have already been answered on the other page where you posted questions. Here is the link:

Andrew Gibson's other question posting.

It's better to keep questions and answers in one thread -- much less confusing. If you have followup questions, post them there.

If you do an interior perforated drain, what is the rest of the wall detail look like? I've seen advice to replace the slab air tight to the wall. Wouldn't it be a better long term solution to have a dimple mat leading to do the drain with an air tight seal around the mat.. and then attach 2" EPS to the dimple mat?

Andrew,

I've seen both approaches used successfully. In some cases, there is evidence that water is leaking through the wall. (Some homeowners can observe water trickling out of wall cracks during a heavy rainstorm.) That's the kind of case that probably requires the installation of dimple mat against the wall.

In other cases, the water shows up as a puddle on the slab. This latter situation probably doesn't require the dimple mat.

For me, the water issue is the latter. My concern is "what if water *eventually* comes through the wall after I seal it with insulation?" - is it worth doing the dimple mat as an insurance policy against future wall leaks?

Andrew,

Considering your concern, and the likelihood that your concern will lead to insomnia, I recommend the installation of dimple mat in your case.

Quote for excavate around existing firldstone basement

We want a quote for excavating around our Victorian-era fieldstone basement, insulating, parging. Anyone know a contractor near MA-NH-VT intersection we can get quote from? A decade ago an excavator graded earth downward around whole foundation. We tried pointing gutter downspouts far far from foundation. We had a “basement waterproofing” contractor dig full interior perimeter then install drainage pipe, dimple flange and electric sump that empties to daylight. Another contractor painted interior face of fieldstones with elastomeric. We run high capacity dehumidifier constantly. Eaves and rakes have no overhang but we are in process of correcting that. We now need additional home office space yet are stuck with a wet dungeon in our “forever” house. We dont even know what terms to google: “excavation/foundation contractor”? Anyone know anyone who does the work we need?

I'm in a 113-year-old brick house, with brick foundation walls all the way to the foundation (about 5 ft underground). Does the guidance provided in this article apply equally to someone in my situation? Notably, you (Martin) have written elsewhere on GBA that when insulating *interior* brick basement walls, closed cell spray foam is the only wise choice. If I want to apply insulation over the (exterior) dampproofing layer, can I get away with XPS board or do I need spray foam?

Brooklynite,

Q. "If I want to apply insulation over the (exterior) dampproofing layer, can I get away with XPS board or do I need spray foam?"

A. You can use rigid foam on the exterior side of your brick basement walls. But most green builders avoid using XPS, because XPS is manufactured with a blowing agent that has a high global warming potential. Use EPS instead. For more information, see these two articles:

"Choosing Rigid Foam"

"How to Insulate a Basement Wall"

"Unless you are planning to have a basement bedroom, it’s best to eliminate basement windows, since windows can provide paths for water leaks."

This is something I've been wondering lately: what is the function (both present and historical) of windows in an unfinished basement in a cold climate (Toronto)?

Are basement windows included in new homes with the assumption that all basements will eventually be finished? Assuming the basement is dry (and won't ever be finished), is it always better to fill-in the windows and insulate the area?

Thanks,

Drew

Drew,

In all the old houses I've lived in in Montreal and Toronto, they seemed like very ineffective attempts to introduce some light - and it would have been no loss if they weren't there.

I guess the problem now is that, unlike not including them in the first place, trying to seal them up doesn't necessarily eliminate the chances of water infiltration. It still seems like a good idea to me though.

Drew,

Older homes were built in the days before electricity. Windows provided light for those who went downstairs to get carrots or potatoes. Windows could also be opened in October to bring in cool air, thereby cooling the basement before the winter crops were brought in for storage.

There is no logic to including windows in a modern basement. They're there because they've always been there. In some cases, builders feel that providing a means of ventilation is helpful -- although it rarely is. (In fact, ventilating a basement with outdoor air in summer almost always causes more problems than it solves.)

Thanks Malcolm and Martin for the insights.

"They're there because they've always been there." - this is what I was looking for.

"There is no logic to including windows in a modern basement. They're there because they've always been there. In some cases, builders feel that providing a means of ventilation is helpful -- although it rarely is. (In fact, ventilating a basement with outdoor air in summer almost always causes more problems than it solves.)"

I have a different view on this. Modern basements are increasingly designed for prime living space, whether they be in law suites, bedrooms for teens, media rooms and gyms. Ceilings are getting higher and natural light is desirable and egress in the case of bedrooms is required. Of course, these have to be designed in the basement with larger window wells with proper drainage. I do agree that the cheap leaky small vinyl sliders that builders put in are not that useful.

Allan,

The sentence from my article that inspired this discussion reads as follows: "Unless you are planning to have a basement bedroom, it’s best to eliminate basement windows, since windows can provide paths for water leaks."

Obviously, if you are planning to have a basement bedroom, an egress window is required. It should also be obvious that if you are planning to use your basement as finished space, natural light will probably be desirable and should be planned for. (Whether or not finished space should be below grade or above grade is an entirely different discussion; in my mind, if you are able to plan ahead, the finished space should probably be above grade.)

I wrote about this issue more extensively in another article, "All About Basements." In that article, I wrote:

"If you live in an older home, and you know that your basement stays dry, you may be tempted to transform your basement into finished space. As long as you understand the expense and the risks of this approach, you can certainly turn your basement into almost any type of room you want. ...

"When it comes to the advisability of transforming a basement into finished space, opinions differ. Here’s my opinion: basements are different from above-grade space, and that’s OK. In many homes, the basement is an informal space where people can retreat when they want to relax or make a mess. A basement is a good place for a ping-pong table, for a sturdy shelf to hold home-made jam and pickles, or for a work bench to tinker on small projects.

"If the basement is finished into a carpeted home theater, and the work bench is banished to the garage, the house hasn’t necessarily been improved. In my opinion, the trade-off probably isn’t worth it.

"An honest, unfinished basement with a concrete floor is preferable in all respects to a finished room with damp carpeting."

Log in or become a member to post a comment.

Sign up Log in