One of the challenges facing heat pump installers is the high cost of balance-of-system components. These components, which include copper line sets and coverings, electrical cables and devices, and other required accessories, can account for a third or more of material costs in a typical installation.

One potentially expensive item is the mounting system—the bracket, stand, or riser—that holds the heat pump’s outdoor unit off the ground. Elevating heat pumps is necessary to ensure their performance and durability. Here, I’ll talk about why we elevate heat pumps and how high they need to be. I’ll discuss the pros and cons of wall-mount and ground-mount approaches. Then, I’ll look at specific products, including leading brands and lower-cost alternatives.

Why elevate heat pumps?

Conventional air conditioners are often set directly on ground-mounted concrete, polypropylene, or cement-coated foam-core pads. But heat pumps must be elevated for several reasons:

Snow. Heat pumps provide both summer cooling and winter heating. Snow accumulation can block the airflow these units need to capture heat from outdoor air.

Raising the heat pump above snow depth can also reduce the amount of energy used in the defrost cycle. In normal heating operation, frost builds up on the outdoor coil, restricting airflow. Modern heat pumps can sense this buildup. They stop delivering heat to the house and briefly go into reverse, using heat from the compressor and the indoors to melt the frost.

When snow is sucked onto the coil, it can increase the amount of time the heat pump spends defrosting. For example, during a 2015 blizzard on Martha’s Vineyard, Marc Rosenbaum found that defrost frequency went from roughly once every four hours to about once per hour. The defrost cycles also took longer, increasing from 4 to 5 minutes to about 15 minutes.

When a…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

4 Comments

Jon,

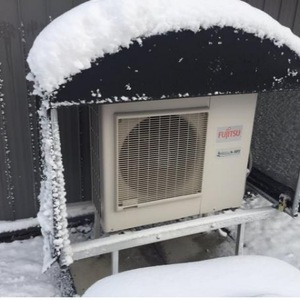

I don't know much about cold weather. Would snow accumulation on the unit, like is shown in the first photo, cause a problem? Ideally, would it be worthwhile to mount a separate small roof over it?

Hopefully these stands will evolve to look a bit less utilitarian, and more like garden furniture.

Hi Malcolm. I would not be concerned with the unit in the photo. It has an aftermarket hood so that when the snow melts, it drains toward a gutter at the front of the unit, which channels it away from the fan and heat exchanger.

I do really like the idea of separate roofs or awnings, particularly in high-snow areas and when a large mass of snow might slide off a metal roof and damage a unit. I'm hoping to write a review of some hood and awning options in the near future.

Agreed about the aesthetics! I think there's a business opportunity there for more elegant designs.

Thanks Jon. Over the years I’ve tried a number of mounting options, but not as many as you lay out. I’ve done a fair number of the standard pad+stand installations. I don’t particularly like them—partly because of the expense but mostly because to me they usually detract from the building.

One option I’ve used is solid masonry blocks 4 by 8 by 16 stood vertically 8” and tapconned to the unit and pinned to the pad. It less obtrusive than a stand and it’s certainly cheap, but the lack of ground clearance can be trouble in heavy snow and long cold snaps. I’ve considered making a form and pouring my own 12” risers but haven’t gotten around to it. I think you could do a run of them pretty efficiently.

I’ve found that using wall brackets has a couple of advantages. When it’s off the ground and tucked close to a wall, the heat pump integrates well and reads more like part of the building instead of some alien appurtenance. To my eye anyway. And if the back of the unit is only 5 or 6” from the building I can sometimes take advantage of eve overhangs.

Of course this usually means mounting on a masonry foundation to avoid the problem of noise transfer. The Quicksling QSWB 1000 and 3000 work well for this if you’ve got 12- 18” or so of masonry above grade. They aren’t cheap and I usually have to modify them to put the unit closer to the building, but if a couple hundred bucks and a bit of drilling make for a good looking installation, then everybody’s happy.

I look forward to your awning article. I’ve had little luck there.

When I had my house built in Colorado, the installer didn't put a roof on the condenser or raise it above the snow level. I use the mini-splits mostly for heating and occasional cooling. Occasionally, we can get a couple of feet of snow in a single storm. Mostly, I would go out and clear it off when it snowed. But, that wasn’t a good solution. So, I decided to raise it. Mounting to the house was difficult because of the metal wall panels and it is right outside my bedroom so I didn’t want to have any noise issues.

I used the 24” QuickSling Stand and the Quick Sling Roof. The roof creates a large separation from the unit so snow does not rest directly on it. The unit on the 24” stand would be top heavy in the windy weather we get so I wanted this to be anchored to the ground. A regular concrete pad would probably would have been fine, but, I was not confident in my ability to make a pad that would be flat and level. Also, I wasn’t sure that the soil wasn’t moving around since it was at the edge of a steep slope. So, I used 4 large (mailbox post) ground screws to keep them level, pressure-treated wood “beams” to support the QuickSling stand and screwed it all together.

It still looks pretty utilitarian and it may be overkill, but I’m satisfied with the way it turned out. The largest expense was having the condenser removed and reinstalled at the new height. So far, after two winters, the snow has not been a problem.

Log in or become a member to post a comment.

Sign up Log in