Image Credit: Image #1: Mike MacFarland, Energy Docs

Image Credit: Image #1: Mike MacFarland, Energy Docs Compression at the support straps of this well-installed duct system reduces the R-value.

Image Credit: Image #2: Energy Vanguard

If you know a little building science, you’ve no doubt seen a lot of problems that occur with air distribution systems. Ducts just don’t get anywhere near the attention they deserve in most homes.

I’ve written about ducts quite a bit here and have shown problems resulting from poor design and installation. We all know how stupid some of those problems are. So today I’m going to talk about a problem that doesn’t get nearly enough attention: duct insulation — even when the design and installation are perfect.

OK, maybe the design isn’t quite perfect. If it were, all the ducts would be in conditioned space. That would be the smart thing to do and would make duct insulation less important. What I’m talking about is a house with ducts in unconditioned space, especially an unconditioned attic.

Our R-value cognitive dissonance

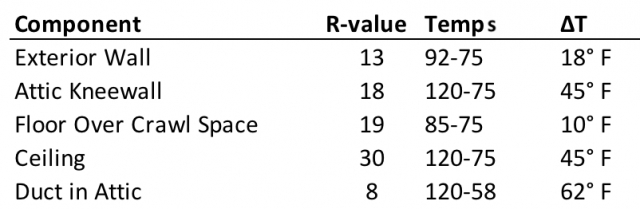

I’m in Georgia (IECC Climate Zone 3), where our current state code requires R-13 in exterior walls, R-18 in attic kneewalls, R-19 in floors, and R-30 in ceilings. If we put ducts in unconditioned space, they have to be insulated to either R-8 (if they’re in an unconditioned attic) or R-6 (in any other type of unconditioned space).

Have you ever considered the temperature differences (delta-Ts) across those different insulated surfaces? Let’s take a look at what they would be on a summer design day here in Atlanta. The outdoor temperature would be 92°F. The indoor temperature would be 75°F. Crawl spaces can vary a lot, depending on how much above-grade foundation wall there is, but 85°F is typical. Attic temperatures are about 120°F. And conditioned air inside a duct is about 58°F. So the delta-Ts would be:

I don’t know about you, but when I look at that, it seems we may be prescribing too little insulation for ducts in unconditioned attics. The largest delta-T in the house has the lowest R-value. Hmmmm.

How much load does thin duct insulation add?

As Kai Rysdaal says every day on MarketPlace, let’s do the numbers. I pulled up a job we did a few years ago to play around with different scenarios. The house is about 3,500 square feet, all on one floor. All the ducts are in the attic. According to RightSuite (the software we use), there’s about 560 square feet of surface area for the supply ducts and 101 square feet on the return side. Looking at the cooling load only, the additional load would be:

R-8 duct insulation: 5,227 BTU/hour

One ton of air conditioning equals 12,000 BTU/hr, so this would be almost half a ton (0.44) of cooling load.

But what if you have an older house that doesn’t have R-8 duct insulation? Or you live in a state that doesn’t require R-8 on the ducts? (I’m looking at you, Mississippi and Alabama.) R-6 and R-4.2 are common R-values for ducts. Here’s how that 3,500 square foot house would come out with those:

R-6 duct insulation: 6,305 BTU/hour (0.53 ton)

R-4.2 duct insulation: 7,948 BTU/hour (0.66 ton)

The numbers are even higher for the additional heating load.

Some other factors to consider

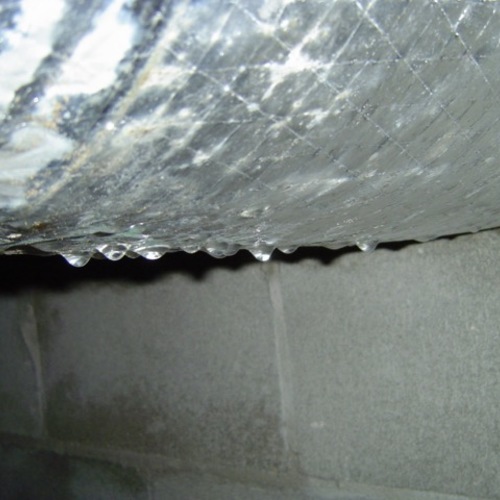

The duct insulation R-values I mentioned above are what’s on the product label. How often do you think you get the full labeled R-value? Even with a really nice installation, as in the photo in Image #2 below, there’s usually compression at the supports.

And then there’s the issue of how the R-value on the label is determined. That’s a topic worth its own article, though, so all I’ll say here is that when a product is laid out flat for testing and then installed cylindrically, the actual R-value likely isn’t the same as what’s on the label.

What are the remedies?

Unconditioned attics are the worst place to put ducts. If you’re facing that as one choice for a new home or if you already have that in your existing home, here are some ways to reduce your duct losses:

- Get the ducts out of the attic and into the conditioned space below. Doing this results in zero additional load.

- Encapsulate the attic. This isn’t equivalent to bringing them into the conditioned space as you’ll still have additional duct load but it’s a lot better than having them in unconditioned attic space.

- Bury the ducts deeply in insulation. That’s what happened to the ducts in the lead photo of this article. That’s one of Mike MacFarland’s jobs in northern California, where burying ducts is a no-brainer. In humid climates, burying ducts can be a risky strategy.

- Replace your ducted system with ductless mini-split heat pumps.

- Go with hydronic distribution and keep all the pipes inside conditioned space. Use water instead of air to move heat into or out of the conditioned space.

We’ve gotten new homes to be much more efficient in the past decade because of energy codes that require blower door and duct leakage testing, better windows, and higher levels of insulation. Now it’s time to focus on the next level of problems. And that means it’s time to deal with duct insulation in a more meaningful way than just increasing the required R-value to 8 for ducts in attics.

Allison Bailes of Decatur, Georgia, is a speaker, writer, building science consultant, and the author of the Energy Vanguard Blog. You can follow him on Twitter at @EnergyVanguard.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

4 Comments

Great article - but temp difference in the returns?

Dear Allison: Thanks for the great article. A couple of additional points: Even with ducts running in 'conditioned' space, leaks and inadequate insulation mean that homeowners are paying to deliver a bunch of hot / cool air to the wrong place -- maybe cooling / heating an attic storage area, for example. So it pays to carefully seal all of the joints and add insulation to duct runs no matter where they are.

A few questions: In your 'additional load' calculations, did you account for the difference in air temperature for returns vs supply? The R-values used for the comparison to walls and crawl spaces also appear to be incorrect; if you place a duct in a wall or crawl space, it would not benefit from the R-value of the complete assembly, filled with insulation. You would have to build duct chases inside walls, and add insulation around ducts in crawl spaces. We recently did the later for a project in Massachusetts, where a duct had to run under a floor. We built a box around the insulated duct with XPS foam board, to improve the insulation.

What is a good duct insulation R value for short run AC ducts in conditioned space? This happens to be for a PH and my main concern is avoiding condensation.

I stumbled across this post while researching duct insulation types for a system I'm planning. While you make some very good points, your example is misleading. Those theoretical heat losses due to insulation values assumed that your fluid is sitting perfectly still inside the ducts (I think, hard to say without seeing math but those numbers are high). In which case, yes those values are correct. However, you are not accounting for the film coefficient of air (also known as the convection coefficient, h) moving inside the ducts. Which is dependent on the flow rate of the air and is found using internal flow equations and Nusselt number relationships, or you can assume it to be constant, but it needs to be accounted for. Essentially this adds a significant amount of thermal resistance to the system and the faster the air moves the more resistance is added because the air has less of a chance to lose it's heat or absorb heat.

Assuming air is moving at 500CFM in an 8" circular duct, reasonable assumption for a trunk size and laminar flow. Ambient temperature is 5F (design temp at my location) and temp leaving the AHU is 120F. This deltaT will be larger than the deltaT of cooling at my location so this heating loss will dominate. The drop in temperature over a 100ft run would only be 2.6F (see link below).

Q(loss) = m*cp*T = 500*60*0.0765*0.24*2.6 = 1,432 BTU/hr. Since 500CFM is about the typical air flow rate for a 1 ton system this would mean your duct losses are only 12% of your load.

Now actually doing out the math and calculating the effective film coefficient based on duct diameter and using 560ft2 of supply area in your example:

Nu = 4.36 = (h*D)/k using Nu=4.36 assuming constant heat flux and laminar flow

D = 8", k(air) = 0.015

Therefore: h(inside duct) = 0.0981 BTU/(hr-ft2-F)

Assume h(outside duct) = 1.2 for natural convection

R = 8

Req = 1/h + R + 1/h this is a simplification and I am not using the exact equations for a duct or pipe

Req = 1/1.2 + 8 + 1/0.0981 = 19.03 (hr-ft2-F)/BTU

Q = deltaT*A/R = (120-5)*560/19.03 = 3,384BTU/hr

Judging by the size of the house in the example, 3600ft2, it it likely a 5-6 ton system? Depending on location and construction. Therefore the loss/capacity would be 3400/72000 = 4.7% or expressed as 566BTU/ton. Granted this also makes some assumptions as I tried to outline above. I also neglected the return area since the deltaT will be ~1/2 in my case.

Sources:

https://www.wbdg.org/guides-specifications/mechanical-insulation-design-guide/design-objectives/temperature-drop-calculator-air-ducts

"Essentially this adds a significant amount of thermal resistance to the system and the faster the air moves the more resistance is added because the air has less of a chance to lose it's heat or absorb heat. "

I don't get it, wouldn't the energy loss be greater if the air is moving through the duct then if it were static? The delta temp is greater after all, along with it, greater energy transfer (heat into the colder side). Perhaps I am misunderstanding you. Higher air speed also only means (to me) that even though it is less effected by the duct, it doesn't matter, because that same cubic foot of air runs through the duct more times per hour to pick up the energy loss it missed the last time. Are you forgetting about recirculation in your calculations? Thanks

Log in or create an account to post a comment.

Sign up Log in