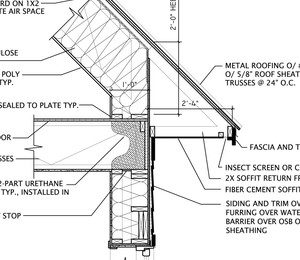

Together, double-stud walls and floor trusses make an efficient building assembly.

Double-stud walls offer a thermally broken wall option that can be easily adapted to meet performance needs in many cold-climate locations. The idea is to increase the space between the walls to increase the overall R-value or, conversely, make the space smaller if less insulation is needed. Double-stud assemblies are easily understood by most carpenters because they are essentially two conventionally stick-framed walls.

Floor trusses are resource-efficient, can be engineered to span the wide-open spaces popular in today’s homes, and their open webs make mechanical runs—including ductwork—easier to plan and install than other joist options.

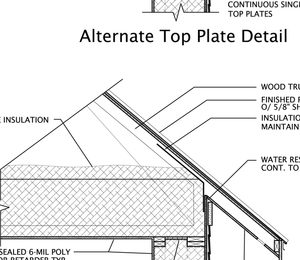

In this detail, where the first-floor walls meet the floor system above, the trusses are shortened by 1 in. to allow space for rigid-foam insulation to be installed as a thermal break at the rim. Another piece of rigid-foam insulation is used for an air barrier and vapor retarder above the interior wall. Note that the double-stud wall in the lower story has fire blocking installed between the top plates and includes an interior polyethylene vapor retarder. The fire blocking is a must for safety. The interior vapor retarder will not be the right option for all houses.

Shortened trusses create space for a thermal break

Without the right planning, rim joists can be difficult areas to control air, heat, and vapor. In this detail, primary air-sealing is done at the exterior sheathing and vapor is controlled at the interior of the rim area with foil-faced rigid-foam insulation, which is sealed with canned spray foam to act as a secondary, interior air barrier. Any insulation could be used to fill the rim area, but if the trusses were run all the way to the sheathing, there would still be significant thermal bridging. By reducing the overall length of the floor truss by 1 in., a space is created for continuous rigid-foam insulation between the ends of the trusses and the wall sheathing to mitigate the thermal bridging.

Floor systems with trusses are typically designed by an engineer or truss designer and the minimal bearing dimension of the truss on the wall’s top plate is specified. If you are considering this detail, make sure the truss designer knows of your plan to include the continuous rigid-foam insulation and make sure the minimum bearing required on the top plate of the exterior wall is met. The blocking running along the top corner of the floor trusses is a standard detail to hold the trusses plumb during installation. In this case, it offers additional backing for rigid foam as well.

Fire blocking is required between floors

In the unfortunate event of a fire, wall cavities can act as chimneys and accelerate the fire’s spread. In many common walls, the top plate acts as a fire stop. In a double-stud wall, you will either need an additional top plate that connects the two walls—commonly ¾-in. plywood—or you will need to add blocking to prevent fire from spreading from the first floor to the floor assembly above and ultimately the second floor. If you are not adding a plywood top plate to your assembly, gypsum wall board (GWB or drywall) or ¾-in. plywood can be installed between the walls’ top plates, as shown. Verify that your choice of material is rated for use as fire blocking.

Interior vapor control

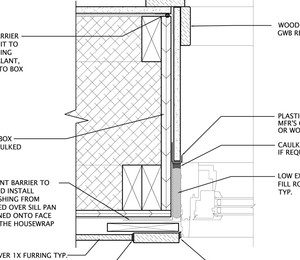

Whether an interior vapor retarder is required in your assembly will depend on the climate zone you are building in and the details of the assembly. The polyethylene vapor retarder shown here should only be used in the coldest climates and in buildings that are not air conditioned. Many high-performance builders prefer more forgiving variable-perm, or “smart” vapor retarders that allow more vapor to pass in humid conditions and therefore allow walls to dry more readily. In many areas the building codes will allow a Class III vapor retarder (commonly painted drywall), if the assembly includes a highly recommended rainscreen gap between the sheathing and siding. Both can be detailed as an interior air barrier like the poly sheeting shown here.

Framing tips

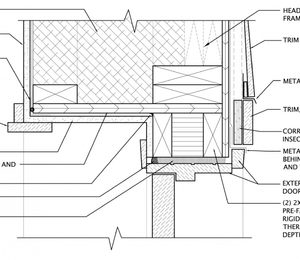

Though this detail shows an outer 2×6 wall and an inner 2×4 wall, double-stud walls are most commonly built with two 2×4 walls. The outer wall is the load-bearing wall. For this reason, some builders have tried using 2×3 lumber for the interior walls to save money. The savings in material are often reported to be more of a headache than it’s worth, as 2x3s are more likely to be bowed and twisted than 2x4s. Also, because the outer walls are load bearing, they can be built first, with floors above and the roof framed before the interior walls are built, which gets the building dried in faster. When framing the inner wall, the studs in the two walls can be either aligned or staggered, but they must line up perfectly at the rough openings. The rough openings are often joined together using plywood or OSB to contain insulation in the walls and give carpenters fastening for drywall returns or extension jambs, which will be needed in these thick walls.

Double-stud walls have become a go-to, high-R-value assembly for cold-climate builders who value energy-efficiency and comfort. For more on how to get double-stud walls right, we recommend the following articles:

How to Get a Double-Stud Wall Right

The Mythical Threat to Double-Stud Walls

Thermal Bridging: How It Works

An Intro to the Four Control Layers