The design load is what the equipment capacity should be based on, but there are two other types of heating and cooling loads that are important to understand.

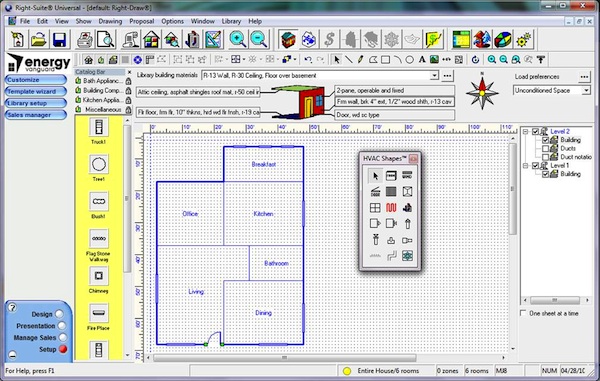

Image Credit: Energy Vanguard Manual E (for eyeball) is a method for determining the size of air conditioner to install in a home...but not an accurate one.

Image Credit: Energy Vanguard

What is it about the number three? You’ve got the Three Musketeers, the Three Little Pigs, and the Three Stooges. Then there’s three strikes (what every pitcher wants), three branches of government (executive, legislative, and judicial), and the three kinds of people (those who can do math and those who can’t). And let’s not forget three on a match, three wise men, and threepeats.

Today we’ll look at another big three: the three types of heating and cooling loads. Do you know what they are already?

Load vs. capacity

Before we get into the three types of heating and cooling loads, though, it’s a good idea to make sure we’re all clear on the difference between two words that are easy to confuse: load and capacity. If you’re new to HVAC lingo, it’s easy to miss the distinction so here it is:

Load – the amount of heating or cooling a building needs

Capacity – the amount of heating or cooling a piece of HVAC equipment can provide

Whenever you see the word “load” in the context of heating and cooling, it refers to the building’s needs. When you see “capacity,” it’s what the heating or cooling equipment can provide.

Got it? Great. Let’s get to those three types of loads now, knowing that we’re talking about building needs.

Design load

If you ask a competent HVAC designer what the cooling load on a house is and they tell you it’s two tons, they’re talking about the design load. That means they’ve calculated the amount of cooling needed for the house using plans and specifications for the house or actual field data for existing homes. Mostly the inputs in the calculation are constant (e.g., insulation R-value, house orientation…), but some things change throughout the day or year (e.g., outdoor temperatures) and some can be changed by the occupants (e.g., indoor temperatures).

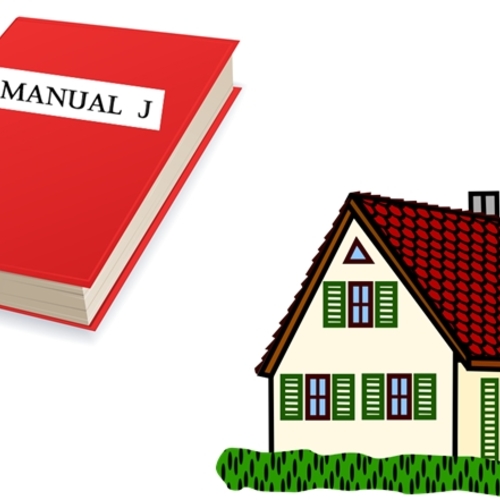

Calculation protocols like ACCA Manual J specify the temperatures you should use in the calculations, and these are called the design conditions. For example, our outdoor summer design temperature in Atlanta is 92° F. ACCA’s recommended indoor summer design temperature is 75° F. For winter, Atlanta’s numbers are 23° F and 70° F.

So your design cooling load is how much air conditioning you need when the indoor and outdoor temperatures are at the summer design levels. The design heating load is how much heating you need when the indoor and outdoor temperatures are at the winter design levels.

Extreme load

Unless you live in a place like Santa Monica, California — where the temperature is always perfect — you probably understand that design loads are simply a guide. A house will never spend a whole lot of time subjected to design conditions, so if you size your heating and cooling equipment to meet the design loads exactly, you’ll have the wrong size equipment most of the time.

Extreme loads happen when you get the hottest or coldest temperatures your location experiences. In Atlanta, we got down to single digits Fahrenheit last year, nearly 20 F° below our design temperature. In the summer of 2012, we set a record with a high temperature of 106° F. Should we install HVAC equipment with the capacity to meet the loads from such extreme temperatures?

The answer is no. First, if you do a Manual J load calculation accurately, it’s got some built in padding. The loads you calculate will probably be 15-20% higher than the actual load at design conditions, which gives you a buffer to help meet the extreme loads.

Second, unless you live in a leaky, uninsulated sieve of a house, there will be a lag between when the extreme temperatures occur outdoors and when the inside of the house feels the effects. By the time the heat from that 106° F day starts getting to the inside of the house, the outdoor temperature has already dropped. That’s one of the ways insulation and air sealing help you.

Third, extreme temperatures occur for about 1% of the time on average. Yes, there will be years with heat waves and years with cold spells, but HVAC equipment sized according to the design loads and ACCA’s Manual S equipment selection protocol should cover you for most of the extreme loads you experience.

Extreme loads get more attention than they deserve, in my opinion. If you’ve got a home that’s adequately air-sealed and insulated, properly sized equipment should do fine. If your home isn’t air-sealed or insulated well enough and your HVAC equipment can’t keep up, attack the building enclosure and distribution system before installing bigger equipment. (For more on what you can do if your equipment doesn’t keep up, see the article I wrote shortly after we set the high temperature record in Atlanta, 9 Uncommon Tips for Keeping Cool with a Struggling Air Conditioner.)

Part load

Extreme loads always seem to get the spotlight, but part load conditions are actually more deserving of your attention. For nearly 99% of the time, the outdoor temperatures will be less extreme than the design temperatures for your location. Think about it. You get up on a summer morning, look at the thermometer, and see that it’s 73° F outdoors. Maybe it’ll climb up to your design temperature in the afternoon, but even then, it won’t stay there very long.

So even on a day when you hit the design temperature, your heating or air conditioning system will be operating under part-load conditions most of the day. Another factor is the seasonal change in conditions during the cooling or heating seasons. Early and late in the season, every day will be a part-load day.

The problem with part-load conditions is that most heating and cooling equipment operates at fixed capacity. If the cooling load is only 6,000 BTU per hour and you have a 24,000 BTU/hour air conditioner, that AC isn’t going to run very long before it meets the thermostat setpoint. That imbalance isn’t ideal for comfort or dehumidification.

As houses get more airtight and better insulated, the imbalance gets worse. With fixed capacity equipment that comes in minimum capacities of 1.5 tons for air conditioners or 30-40 thousand BTU/hr for furnaces, it’s easy to have equipment that may never come near needing its full capacity in small, energy-efficient homes. Then if you overventilate by trying to follow the guidelines of a standard like ASHRAE 62.2-2013, you may end up growing mold in a humid climate.

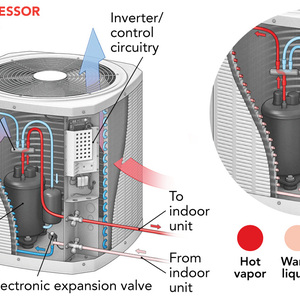

Yes, there are ways around the problems. You can put in some supplemental dehumidification or use two-stage heating and cooling equipment. Or you could go a step further and put in fully modulating equipment like minisplit heat pumps. It’s important to understand the nuances of heating and cooling loads and the ramifications of the type of equipment you choose. The HVAC design world isn’t as simple as it used to be back when you could use rules of thumb or silly protocols like Manual E (shown below). Actually, it never was that simple.

The hip bone’s still connected to the thigh bone, which is still connected to the knee bone. That’s three things, so I hope that means I’m in the group that can do math!

________________________________________________________________________

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a bestselling book on building science. He also writes the Energy Vanguard Blog. For more updates, you can subscribe to our newsletter and follow him on LinkedIn.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

7 Comments

Fully modulating HVAC systems

Fully modulating HVAC systems should be the only units installed at this point in time. No need to discuss how to rub two sticks together for a cave fire is there now? Well except for the survivalists and the maximum resiliency people and if applying to be on the show Survivor...

I like the Manual-E method!

I wonder how they chose 103' rather than a round number like 100'. I'm not sure how they figured you wouldn't poke your eye out with the ruler keeping the paper exactly 12" from your eye too, but I s'pose that was the point! :-)

The "fully" in "...fully modulating..." is really something that doesn't really exist. While there is quite a modulation range, some mini-spits have no more than a 3:1 turn-down ratio. It's still important to right-size them ( or at least "reasonably size" them ) to be able to have them modulating most of the time, to most comfort & efficiency out of them.

Fully modulating isn't a necessity

The SEER rating process has given air conditioner manufacturers strong incentive to reduce cycling penalties, and they've done so. The efficiency difference between a 'right size' 2 ton unit vs a 3.5 ton unit is about 1%. A study in Wisconsin found no difference in indoor humidity when two stage units were forced to run in high stage only.

There are of course other benefits to fully modulating systems, but their benefits aren't so overwhelming that simple single stage systems don't have their place.

Easy to fix

I use the Piahoo method for home design. I reverse the design of the house (size) based on current offered single stage system capacities. In my climate 1.5 for 1600 sq. ft. 2.0 for 2000 sq. ft. (yes i make it a little leaky to make up the difference), etc. Think of all the money I save on Manual Js, etc. I am not sure this "reverse rule of thumb" works, but I have thoroughly convinced all of my clients I know what I am talking about (which is the most important thing after all) , I also include Cardigans / house slippers / wool socks / hand fans / hot water bottles / ice water bottles / silk underwear / mosquito nets, and antiperspirant with each home purchased.

Am I worried about mold damage or occupant comfort? Not really.

errata

I also think Allison is right on on most all his points and a video I saw of an interview with him, where he stresses the supreme importance of a good distribution system.

efficiency vs. comfort (response to Tim. C.)

While the efficiency hit from a unit that is only at 1.75x perfect-sizing isn't much, it's at the threshold of being a comfort issue due to the shorter cycles. (If most installations were ONLY 1.75x oversized there wouldn't be much discussion about it anyway! But "typical" is more like 2x+.) At 1.75x oversizing most people would still be fine, even for a single-stage unit.

But right-sizing it, whether single stage, multi-stage, or modulating is still the right thing to do. The strain on the grid resources is lower , the comfort is at LEAST as good, and the upfront cost is a bit lower to boot.

Within 10 years some utilities will be applying demand-charges, a fixed fee related to your largest 30-minute or 1 hour draw to cover infrastructure costs, rather than rolling it into a fixed per-kwh energy use rate. This will be in part a way to deal with diminishing kwh use by net-metered solar customers, but to be truly fair it has to be applied against all customers. (This is a common mechanism for commercial customer billing, and demand charges are often the biggest fraction of the bill for those customers.) Oversizing an air conditioner will increase the demand charge (an rightly so), since it takes more grid infrastructure to support the bigger load. Even if it's only running 30-35 minutes/hr under design conditions, it's much more abusive to the power grid than a right sized unit running 55-60 minutes at a time.

Blower loads

I'm surprised I don't see more mention of the blower load problem. For example, my largeish home in 5b (~2500 above ground sf, ~50k heating load) has a 5 ton blower motor and the manual D says it isn't big enough. Multiple hvac guys have suggested two furnaces (each nearly capable of meeting design load) in order to conquer the duct friction rate. My father is currently replacing his furnaces and ac in a southern climate. His quotes are for two 3 ton furnaces in order to get the blower capacity required. That's 6 tons of furnace on a house that likely needs 3.

In some homes, it seems like a single mini split to handle one large load room (great room, combined space LR/DR/kitchen, etc) could potentially eliminate an entire furnace and ac unit that would otherwise be required to service the first floor. Yet, I haven't seen such a system proposed here on GBA, perhaps because the focus is on more modest sized homes (~1500 sf) that can be serviced with a single mini.

Log in or create an account to post a comment.

Sign up Log in