Image Credit: Matthew H

UPDATED on May 15, 2015

Every couple of weeks, someone sends me an e-mail with a description of a proposed wall assembly and an urgent question: “Do I need a vapor retarder?” Energy experts have been answering the same question, repeatedly, for at least thirty years. Of course, even though I sometimes sigh when I read this recurring question, it’s still a perfectly good question.

The short answer is: if your wall doesn’t have a vapor retarder, there is no need to worry. Builders worry way too much about vapor diffusion and vapor retarders. It’s actually very rare for a building to have a problem caused by vapor diffusion.

A while back, I collected seven questions about vapor diffusion, and published them (along with my answers) in a blog called “Vapor Retarders and Vapor Barriers.” Since new questions keep showing up in my In box, I decided it was time for another Q&A roundup on vapor diffusion. Here are nine more questions on the topic.

Q. What is water vapor?

A. Water vapor is water in a gaseous state — that is, water that has evaporated. It is invisible. It is present in the air we inhale, and (in even greater concentrations) in the air we exhale.

When this invisible water vapor moves through building materials, the phenomenon is called vapor diffusion.

Q. Was the information I learned 30 years ago all wrong?

A. In the 1970s and early ’80s, builders were taught that it was important to install a vapor barrier (usually, polyethylene sheeting) on the warm-in-winter side of wall insulation and ceiling insulation. Most textbooks and magazines explained that a vapor barrier was needed to keep the walls dry during the winter, and that walls without vapor barriers would get wet.

This was bad advice, for several…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

84 Comments

Interesting photo Martin.

Interesting photo Martin. Poly over kraft??? Secondly, (although not in keeping with your topic) is evidence of what initially seems to be a very good application of fiberglass batts that appears to have been compromised by another trade. In the bottom of each cavity the batts have obviously been disturbed to the point that each cavity is now compromized. One can't point the finger at the fiberglass material or the application technique in this photo! I see this far too often in the field. Other trades rarely hesitate to displace, damage or destroy the integrity of insulation applications, regardless of the insulating product used. If everyone working on these projects isn't in tune with the ultimate goal, we will find success difficult to attain. Either during inspection, or if and when an infrared image were to be taken of this wall after it is closed up, the insulation contractor will wrongly get the blame. By the way, fiberglass insulation materials are much more user friendly than ever before, especially those that have eliminated the phenolic binders. 20 years ago it was easier to understand why other trades didn't want to take the time to correctly replace batts that were removed. Today's batts aren't dusty or itchy for that matter. No excuse for not replacing them or repairing them.

Response to Chris Brown

Chris,

You guessed correctly: the photo does not show best practices.

Believe it or not, this type of installation used to be very common in Vermont. I used to see kraft-faced batts covered with interior poly all the time. To this day, there are plenty of builders who keep doing it the same way -- that is, the way they learned to do it back in the 1970s.

I'm not a big fan of fiberglass batts, and I think that blaming someone for not quite placing the batts perfectly is misguided. It's far more common to see batts with wrinkles or smushed-in sections than it is to see a perfect installation job -- and the fault lies more with the batts themselves than with the installer.

For more information on the topic, see Installing Fiberglass Right. In that article, I wrote: "It is the nature of a fiberglass batt to want to be installed sloppily. Unlike cellulose or spray polyurethane foam, a fiberglass batt doesn’t volunteer to fill a cavity completely; on the contrary, it tends to fight an installer’s attempt to make it fit snugly."

Martin, I disagree. There is

Martin, I disagree. There is no doubt that that many find fault with fiberglass batts, and you have made it clear numerous times that you do not favor them. However, they are still the most widely used product for thermal applications. My point was simply this: The insulation installer did his job and did it correctly and yet it was compromized by someone else! We should not accept the fact that it could not have been repaired correctly, because it could have been! In the interest of full disclosure, I have been in the insulation business for over 45 years now, as a contractor and now as an employee of the manufacturer who's product is in the picture. My last point (and I will cease hijacking) is this: Do no harm! No trade should compromize the work of others. I know that is idealistic and I get that this is construction. What would it have looked like had this wall been sprayed with loosefill fiberglass, cellulose or foam? I don't care what insulation product was initially used in this wall. It was compromised and would have been regardless of the product used.

Chris Brown: i see 1 major

Chris Brown: i see 1 major fault in this picture

interior insulation ...

unfortunately, foam and or panel type exterior insulation will only rise up in popularity as

informed people such as many on this site ( Martin etc.. ) will push informative questionning and provide documentation to benefits all around.

People need to wake up and realize that 75% trade workers do very very bad jobs, destroys the previously well done jobs , and it will get worse. The new generation of young worker that are chatting on their cell phone while working really don't care at all about quality of work.

( let's assume that less than 25% of the young worker do care ..but i am beeing positivly unrealistic here )

I haven't seen a well done tile job in many many many years now, even in high end restaurants ,

hotels, luxury homes ..

Electricians drill holes wrong place in beams, destroys wall insulation and integrity...

Gypsum guys leave a mess in the walls cavity that "haunt" the future owners for 100 yeasr

( my parents house has had dust problems because of sanded dust at the bottom of inner walls partitions )

This will not change, however, using foam insulation at the exterior is much safer as far as integrity goes.

Then, polythene vapor barrier ... i am wondering how many holes per sq ft we would be able to find in most walls if we would be able to peak. Way too easily compromised.

Fiberglass bats insulation is still with us for only 1 reason = economic

Contractors= business= profit = fiberglass bats

Unfortunately, 95% of residential buildings here in Quebec are built using wood framed, fiberglass bats and interior poly sheets !

Good thing now R4 exterior sheathing thermal break for studs is mandatory !!

But again, everyone is trying to solve problems created by a wrong base system.

Vapor Movement

Martin,

When you refer to the governing factor that determines moisture content of siding being its temperature, I assume that you mean this: An insulated building will have colder siding and sheathing than an uninsulated building. When you decrease the temperature of the siding and sheathing, they can hold more moisture, so they will absorb more moisture.

When you say outward diffusion is not that significant, I can see two possible explanations, but I am not convinced by either one. The first and more obvious explanation is that the siding and sheathing, being chilled by the seasonal temperature reduction, will absorb more moisture; and so the vapor pressure in that vicinity will be higher than that of the living space. Therefore, there will simply be no impetus for interior vapor to diffuse outward. I am skeptical that the siding and sheathing can take on so much added moisture that they can cause a vapor migration toward the house interior

The other explanation is that outward diffusion through permeable materials does not move as much vapor as once thought. However, I know of no scientific proof of this.

You suggest that this wintertime moisture increase of the siding and sheathing will need an avenue to dry through during the summer, and for this reason, interior poly should be eliminated so as to permit inward drying to the living space.

Outward diffusion provides a continuous supply of condensing vapor to accumulate wetness day by day, all winter if it cannot escape by adequate ventilation. Whereas, the taking on of higher moisture content by the siding and sheathing due to the lower seasonal temperature is just a one-time adjustment corresponding with the lower average wintertime temperature. It does not continuously deliver moisture that accumulates as wetness, which later needs any extra means of drying. It can’t cause wetting that degrades the insulation, cause water damage, or grow mold. But outward diffusion definitely can cause these problems.

So, I do not see the need to eliminate the warm-side poly vapor barrier just to create the extra measure of inward drying to remove moisture that has built up over winter in the siding and sheathing. That extra moisture taken on by the siding and sheathing over winter can easily escape back to the outdoor air by the same route it came in. And while that moisture exists in the siding and sheathing, it can’t do any harm anyway.

Look at it this way: If the siding and sheathing could take on so much additional moisture over winter that they forced a need of inward drying to get rid of that moisture during the summer; then I would expect the siding and sheathing in winter to be covered with heavy frost that continues to wetting and freezing in the insulation. And even if this were observed, there would be no way to know whether it was being caused by the chilling of the siding and sheathing taking in moisture from the outdoors—OR—if it is being caused by outward diffusion.

So when you eliminate the vapor barrier to permit inward drying of moisture assumed to be coming from the outside, you might enable outward diffusion that would put moisture into the wall. So, the way I see it, eliminating the inward drying (by including a vapor barrier) might also eliminate the need for inward drying. Whereas, eliminating the vapor barrier to permit inward drying might create the very need for inward drying.

Response to Ron Keagle

Ron,

You have challenged me on this issue before, and I suspect that there isn't much I can write that will change your mind. If you want to install a polyethylene vapor barrier on the inside of your wall, you are of course free to do so. Depending on where your house is located, the details of your wall assembly, and whether or not you have an air conditioner, your house may be just fine -- even with interior poly.

You wrote, "When you say outward diffusion is not that significant, I can see two possible explanations, but I am not convinced by either one."

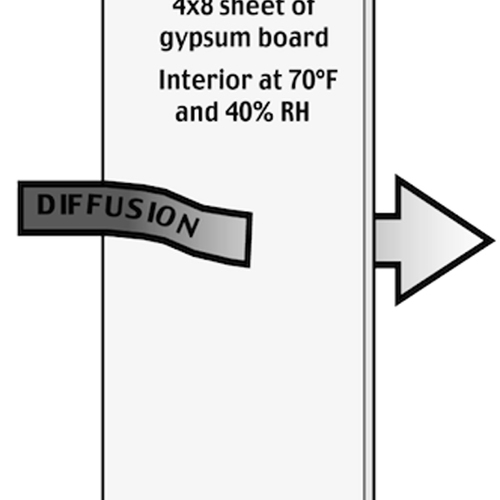

Diffusion has been both measured and modeled, so this question really isn't in dispute. See the Building Science Corp. graphic below -- one that has been widely reproduced -- to understand my point.

You wrote, "When you eliminate the vapor barrier to permit inward drying of moisture assumed to be coming from the outside, you might enable outward diffusion that would put moisture into the wall."

You're right, of course. However, in most climates, eliminating the poly puts you on the correct side of this pushme-pullyu equation -- in other words, your wall assembly will be dryer without the poly than with the poly.

But if you like interior vapor retarders, go ahead and install one. A "smart" retarder makes the most sense for someone with your concerns.

.

Really Ron, do some online research! It's out there!

" I am skeptical that the siding and sheathing can take on so much added moisture that they can cause a vapor migration toward the house interior ."

Happens all the time, very intensely when dew or rain wetted brick or stucco gets heated by the sun. This has been measured and analyzed intensively by building scientists (and publish the data in peer reviewed journals.)

"The other explanation is that outward diffusion through permeable materials does not move as much vapor as once thought. However, I know of no scientific proof of this. "

There's no science to proving changes in opinions. There is plenty of (published) science about how vapor permeance of materials can be measured, and the rates at which moisture can diffuse through assemblies of measured, known ASTM C96 vapor permeance will move under different interior & exterior temperatures & humidities. This has been well studied, and provides the fundamental basis for modeling tools such as WUFI. The WUFI model has been well vetted in academic experimental assemblies as well as field monitoring/verification studies (yes, real "scientific proof", of just how much water vapor moves through walls in an air-tight assembly.)

I'll take the opinions and assertions of those who have spent their careers actually measuring stuff over the speculation of any arm-chair theoretician (even when that theoretician is ME. ;-) )

There's plenty of easy-to-digest compilations of this stuff readily searchable on the Building Science Corporation site, but the the more hard-core science on it is out there too. (Oak Ridge & Lawrence Berkeley National Lab websites are a good place to start too, but many universities with related engineering schools have web-accessible data too.) And that's just the English language stuff- there's plenty of European reasearch & modeling results out there too. (WUFI was originally developed and verified by the Fraunhofer-Institut für Bauphysik, but is now a freebie download from Oak Ridge National Labs. http://www.ornl.gov/sci/ees/etsd/btric/wufi/software.shtml )

If you take the time learn how to use the WUFI tool beyond a "garbage-in = garbage out" level, it can be quite instructive about what a vapor barrier does for/to building assemblies.

Or you can keep making speculative arguments and complaining about how there is proof. But the science on this is mostly DONE, even if you've yet to discover it.

a clarification

Good write up, Just to clarify, both INTELLO, DB+ from Proclima (that my company http://www.foursevenfive.com brings to the USA) and Membrain are smart vapor retarders.

Siga majpell is not a vapor variable membrane. It is 0.7 perm at any humidity.

This can make a big difference, especially if you are talking about solar driven diffusion and or inward drying potential (important under greenroofs or other assemblies that are vapor closed on the exterior) and yes, WUFI will show that these intelligent retarders can make a difference in well insulated assemblies.

Response to Floris Keverling Buisman

Floris,

Thanks for the clarification. I have edited the article to reflect your correction.

i am glad this was brought up

i am glad this was brought up again. i seem to learn a little bit every time.

Permeance is the secondary concern

Matin & Floris,

Thanks for the correction on the permeance of SIGA Miajpell.

Yes it has a fixed value. The overarching issue that it's trying do deal with is exfiltration (air leaks). In our thoughts and practices, the permeance is really secondary (as is the point of the article) and the task-at-hand is to produce (and use) a strong membrane that's tear and puncture resistant, easy to hang, fits class II permeance (rather than class I or III), as cost effectively as possible. -We're pretty happy with it. :)

Not to take away the features of "smart retarders", but I've got to point out that a fixed class II permeance has significant benefits: You know what you've got, - it's a constant value and near the common condition permeance of basic sheathing products of OSB and Plywood. When we look at proposed wall assemblies in WUFI, it is helpful to have a fixed value. That way we know that the calculations at that layer have the correct input data and there is no further need for interpretation.

It's not rocket science. As we move ahead in building envelop quality (or "enclosure" for those of the BSC ilk), we need simple straight up "exfiltration answers": A simple mind set of "stop the air leaks -but leave some permeance" will take the building industry long way.

Vapor

Jeez Dana, all I did was question a few things. I thought that was the point of discussions such as these. I am not sure what I said that you find yourself so at odds with.

Martin posted a diagram showing a great difference between vapor moving by diffusion compared to vapor hitchhiking on air. But that has nothing to do with my question which was asking for a quantification of diffusion over time.

I said this: "The other explanation is that outward diffusion through permeable materials does not move as much vapor as once thought. However, I know of no scientific proof of this. "

Clearly, this explanation has been given here numerous times, however, nobody has ever given the basis of knowing this. So my statement is 100% true. I did not say there is no scientific proof, although you seem to be reading that into my comment. The point of my comment was this: Why the discrepancy between what is said to be known now versus what was said to be known in the past?

In answer to the above question, from what Martin has said, I would have to conclude the following:

In the past, the claimed amount of vapor transmission due to diffusion was a deceitful exaggeration in order to protect the insulation industry. So diffusion was just a red herring put forth by the insulation industry as a defense against charges by the paint industry that insulation was making paint fall off. Furthermore, nobody bothered to verify it by scientific experiment.

It does raise this question: If the insulation industry falsely accused diffusion of causing dampness to the exterior that harmed paint adhesion, and thus called for a vapor barrier; why did the paint industry accept that remedy for diffusion if diffusion was not the cause? If the remedy was false, paint would have continued to fall off. So why did the paint industry accept the vapor barrier as solving the problem?

I also said this as you quoted in your response to me: “I am skeptical that the siding and sheathing can take on so much added moisture that they can cause a vapor migration toward the house interior.”

Sure I understand that reservoir cladding and bad flashing can lead to an influx of moisture. But if you read the rest of my comment, you will see that it is in the context of wintertime, and targets ONLY the claimed effect of seasonal average temperature drop causing a moisture increase in siding and sheathing.

And this premise that I am questioning goes on to say that the increased moisture accumulates over winter and migrates inward, spreading wetness to the insulation to the extent that inward drying as well as outward drying is needed once winter ends. THAT is the context of my saying, “I am skeptical that the siding and sheathing can take on so much added moisture that they can cause a vapor migration toward the house interior.” I remain skeptical.

Response to Ron Keagle

Ron,

The explanation provided by Teesdale, Rogers, and Rowley was convenient for those advocating the use of insulation, so it was widely believed. To anyone familiar with the history of science, it should come as no surprise that (as you put it) "nobody bothered to verify it by scientific experiment."

Building scientists had an incomplete understanding of air leakage though building envelopes until the 1970s. After all, the blower door wasn't even invented until the early 1970s. When researchers noticed damp sheathing, they mistakenly assumed that the moisture transport mechanism was vapor diffusion -- due in part to their ignorance of the fundamentals of air leakage. (In the 1930s and 1940s, air leakage through building envelopes had not yet been quantified.)

You write, "I remain skeptical." There is nothing wrong with skepticism; after all, skepticism has led to many scientific advances. But as far as I know, the researchers at Lawrence Berkeley National Laboratory, Oak Ridge National Laboratory, the Building Science Corporation, and Fraunhofer-Institut für Bauphysik have made repeated measurements in their labs to verify the principles that I have outlined in this article. You have not. If you want to put forward an alternate (skeptical) scientific theory, I suggest that you start making measurements.

Vapor barriers to prevent offgassing of OSB and CCA treated wood

Thanks Martin for explaining in detail why you recommend not using a Vapor in most instances. It was very helpful.

I am in a mild marine Climate in southern Chile ( similar to Portland Oregon) where likely using a vapor barrier would not cause problems from what I understand.

The house frame upper and lower floor was built with OSB which I understand contains formaldehyde and CCA pressure treated wood. These are common construction methods where I live.

In this case might you recommend a vapor barrier to prevent off-gassing from the CCA wood and formaldehyde in the OSB ?

Thanks

Response to Marion Marshall

Marion,

While water vapor can diffuse through many common building materials, I don't think that formaldehyde or CCA move through materials by diffusion -- at least not to a significant extent. If any chemist or physicist cares to correct me, I am prepared to be corrected.

If you want to prevent formaldehyde or CCA fumes from entering your house, all you really need is an air barrier.

I don't know what you are using as the interior finish material for your wall; perhaps you are using gypsum drywall or plaster. Either of these materials can be installed as an air barrier, as long as you pay attention to air sealing at the perimeter of the materials and penetrations.

If you are worried about offgassing of materials in your wall assembly, here's another suggestion: it might make more sense to install a supply-only ventilation system (which will slightly pressurize your house) rather than an exhaust-only ventilation system (which will slightly depressurize your house).

One of your statements is confusing to me. You wrote, "I am in a mild marine climate ... similar to Portland, Oregon, where likely using a vapor barrier would not cause problems." In fact, the installation of an interior vapor barrier in Portland, Oregon is not recommended, because it could cause problems.

Reply to Martin Holiday

Thanks Martin ..

Your reply clears matters up for me greatly , was a big help and now I have an action plan.

I hadn't thought about using supply only ventilation inside to slight pressurize your house to help with off gassing in a new home. Fortunately we had installed supply only ventilation so I will be using that often in the first year.

Also now I will not be installing a vapor barrier and instead I will be doing air sealing. That is sealing the edges and penetrations of the interior walls which (correct) are gypsum drywall and wood paneling I believe.

One final question per a vapor barrier - a contractor had recommended to me that we seal the fiberglass batts with closed cell polyurethane foam on top of the batts. (flash and batt system but inverted)

I could see how this could more perfectly seal the air cavities but perhaps this polyurethane spray foam would act as a vapor barrier also which is what I believe I want to avoid right now ? Perhaps a bad idea then ? Or Ok to do ?

If so would all closed cell polyurethane spray foam not be recommended for interior walls because it functions as a water vapor barrier and an air barrier (according to wikipedia) ?

Thanks in advance and sorry if I am confusing or misunderstanding the issue like I did with the Portland Oregon reference.

Should I just reply here or the other forum area ? Please let me know your preference

Response to Marion Marshall

Marion,

For more information on air barriers and air sealing, see Questions and Answers About Air Barriers. You should also consider reading some of the articles linked to in the "Related Articles" box on that page.

If you want to follow the "flash and batt" system, the spray foam insulation should be installed on the exterior side of the stud cavities, not the interior side. For more information on the flash and batt system, you can search for "flash and batt" in the search box on the GBA site.

If you want a tight air barrier, you might prefer to use spray foam insulation without any batts. However, a good spray foam installer can create a tight air barrier with just 2 inches of closed-cell spray foam, so either approach can work.

The purpose of the vapor barrier

Ron Keagle asked, "If the insulation industry falsely accused diffusion of causing dampness to the exterior that harmed paint adhesion, and thus called for a vapor barrier; why did the paint industry accept that remedy for diffusion if diffusion was not the cause?"

The point of the vapor barrier is not that it’s supposed to work — for insulation or for paint — technically, but that it’s supposed to be where fingers point when something goes wrong. And things go wrong in only a minority of cases.

When they went looking for buildings with moisture damage they presented a parade of 80 some cases, half of which were crawl space homes in Wisconsin. The vapor barrier “fix” worked for both industries, in the management sense not in the technical sense — it took them off the hook in the handful of cases where things went wrong.

Meanwhile, people pretty much stopped painting houses, and went to aluminum siding, Masonite siding, stained cedar, vinyl, Hardiboard.

The impression that these guys were nefariously contorting building science to their commercial ends is not really true. They were inventing building science, trying to get a handle on things, doing what they thought was best, but were all the while (Rogers, anyway) on the lookout to make sure insulation moved forward. It worked a little, technically. That was good enough, and they may have discovered later that it got them off the hook.

Bill

Question:

Martin,

Regarding the graphic showing the difference between vapor transfer by diffusion compared to transfer by air leakage, I am curious about the effect of the diffusion alone. What were the temperature and RH conditions on the cold side of the drywall for the diffusion measure? What was the time period over which the 1/3 cup of water diffused?

Response to Ron Keagle

Ron,

Here is a link to one of the Building Science Corp. documents that includes the graphic:

http://dc243.4shared.com/doc/RD5UTvRw/preview.html

The assumptions behind the graphic:

1. Interior conditions for both diffusion and air leakage are the same: 70 degrees F, 40% RH.

2. The climate is described as a "cold climate."

3. The time frame is described as "an entire heating season."

4. The diffusion is occurring through one 4x8 sheet of gypsum wallboard.

5. The air leakage is occurring through a hole measuring 1 square inch in a sheet of gypsum wallboard.

The amount of water that diffuses through the drywall under these conditions is 1/3 quart (about 11 fluid ounces), not 1/3 cup.

Thanks Martin. That is what

Thanks Martin. That is what I was seeking.

The purpose of the vapor barrier

Bill, Thanks for your clarification on that point.

wow, incredible !! What a

wow, incredible !! What a difference it makes !! no wonder why we see soo many failures around leaks in cold climates !!

air barrier questions

I recently read the airtight drywall article at Fine Homebuilding and thought it a bit much and wondered if Martin agrees that's the way it must be done, or is there a simpler method to achieve airtight dywall? Unfortunately, it looks like poly is the easiest air barrier to install.

Also, what about using house wrap like Tyvek as an air barrier? Does nailed-on rain screen over the wrap wreck the air barrier? Seems like it would, or is the penetration of a nail through the wrap into solid wood airtight? Thanks for any thoughts.

Marc

open cell vs closed cell spray foam in the roof

Martin,

I am particularly interested in your statement regarding the use of open cell spray foam on the underside of the roof deck in warm attic spaces. as well as cathedral ceilings. My insulating contractor is advocating open cell spray foam to protect against water being trapped in the event of water intrusion from the exterior ( a leaky roof). You caution against this on account of the risk of vapor diffusion (from the interior) accumulating in the roof sheathing. I am currently working on a project with insulation soon to be installed and would be interested in any additional remarks you might have.

Response to Marc Bombois

Marc,

I don't know which article you read in Fine Homebuilding, but if you read the article I wrote, that's the one you should pay attention to. Here is the link: Airtight Drywall.

You wrote, "It looks like poly is the easiest air barrier to install." Actually, very few builders try to use polyethylene as an air barrier any more. It's tricky, fussy work -- more work than the Airtight Drywall Approach. Every polyethylene seam has to fall on top of a piece of framing lumber. The poly seams all need to be sealed with Tremco acoustical sealant, a very messy product known as "black death." And you still need airtight electrical boxes. You also have to figure out a way to seal the poly to the electrical boxes -- which is harder than sealing the boxes to the drywall.

Q. "What about using housewrap like Tyvek as an air barrier?"

A. I don't recommend it. It's unlikely to be as tight as using the sheathing as your air barrier.

Q. "Does nailed-on rainscreen over the wrap wreck the air barrier?"

A. Any fastener that penetrates the housewrap has the potential to introduce an air leak -- including the fasteners used to attach the housewrap to the sheathing. More information here: Questions and Answers About Air Barriers.

Response to Matt Cole

Matt,

I'm not sure what type of information you want. My information comes from Joe Lstiburek and Armin Rudd of the Building Science Corp., who found worrisome levels of moisture in roof sheathing behind open-cell foam in Massachusetts. Their conclusion: open-cell foam sprayed on the underside of roof sheathing is dangerous in Massachusetts or anywhere colder.

Use closed-cell foam, or cover the entire roof assembly with gypsum drywall painted with vapor-retarder paint.

Thanks Martin.

I had read this article by Myron Ferguson: http://www.finehomebuilding.com/PDF/Protected/021229042.pdf

He seals gaps in framing as well as foaming or caulking any gaps in the drywall before taping. Egad. Why do that if tape and compound do the trick? No doubt he gets a good result but is it really necessary? Your article is simpler.

In the name of physics...

If we invoke the name of physics in an explanation, it behooves us to present accurate observations of the essentials of a situation, and to clarify how all the important factors work together to produce the observed results. I don't think sufficient data was presented, to apply physics meaningfully to some of the questions raised in this discussion, especially the relationship of insulation to the moisture content of siding. Furthermore, some of the physics presented doesn't seem to be directly relevant to the questions.

We start with the poorly documented observation from the 20s and 30s, that paint peeled more in newly insulated houses, compared to uninsulated houses. The assertion was made by painters, that greater paint peeling was caused by increased wetness in the siding, brought about by the fact that "insulation draws moisture". But we don't really know if extra moisture was present, if so, how much, and whether increased moisture actually caused the peeling paint. We don't know if increased moisture was present in the insulation, nor where that moisture came from. There are enough unknowns up to this point, to make analysis unreliable, but let's move on.

It's not shown as a direct quote, but someone, perhaps William Rose, says, "When siding is cold, it draws moisture from the surrounding (exterior) air". Why would this be so? It doesn't matter if siding is cold, but rather whether it is colder than the air around it.

Certainly, if siding is colder than the surrounding air, then it could provide a surface on which moisture could condense out of that air. But siding tends to be warmer than the surrounding air, since it is part of the heat-flow path from the warm inside of the house to the cold, outside, wintry air. If the moisture levels in the siding and the air are roughly in equilibrium in the winter, then the slightly warmer siding would release moisture to the slightly colder air. On the other hand, if either the siding or the air has substantially greater moisture, then moisture will tend to flow from the wetter to the drier element. It violates a law of physics for drier air to transfer moisture to wetter siding, in the absence of factors not stated in the article.

Rose says, "At the same vapor pressure, lower temperatures means higher relative humidity and higher moisture content." He neglects to point out that water doesn't maintain the same vapor pressure at lower temperatures. As the link below shows, the vapor pressure of water at around 20 degrees F (-7 deg C) is less than 1/8th of its vapor pressure at 75 degrees F (24 deg C). The second link shows that relative humidity of the air in most American cities peaks in the late summer or fall, not in the winter when temperatures are the lowest.

http://library.thinkquest.org/C004970/reference/vap.htm

http://www.ncdc.noaa.gov/oa/climate/online/ccd/avgrh.html

Given that the houses under discussion aren't experiencing unvarying vapor pressures, nor higher relative humidity from the exterior air in contact with the siding, we would need more information to understand how Rose's comments could explain anything about houses.

There are other dubious assertions in the name of physics in this section of the article, but this post is already long. I'd love to see a more complete and credible explanation of the physics involved in siding, moisture, temperature, and the impact of insulation.

Response to Derek Roff

Derek,

First of all, you raise the question of whether the observations and opinions of house painters in the 1920s and 1930s were correct. While that topic may be worthy of discussion, it is irrelevant to the point in my article. I was giving an accurate account of history -- explaining how vapor barrier requirements became part of our building codes. The account is correct, and the events I summarized led to the code requirements -- regardless of whether the house painters were shrewd observers or sadly mistaken.

Your challenges to Bill Rose's explanations are similar to challenges made on this website by Ron Keagle. Bill Rose has graciously responded to Ron Keagle's challenges in the past. You may want to review those previous discussions. I'll include a couple of quotes here.

In the thread titled Fear of cold plywood sheathing in a cold climate, Bill Rose commented, “Wood moisture content depends strongly on RH of the surrounding air, somewhat regardless of the temperature or vapor pressure at which that RH is achieved. In one project I'm working on, the January outdoor RH is 84%, the January indoor RH is 10% and the June RH, indoors and out, is around 60%. That sort of pegs where the wood moisture content will be, or tend to be.”

In the thread titled Tongue and Groove Ceiling w/ 6mil VB - Enough?", Bill Rose commented, “You pose an experiment of chilling one block and keeping the other one at (room?) temperature. The colder one will get wetter. At freezing temperatures and below, the mechanism can involve forming frost on the surface (not bound water), which, when it melts, gets sucked into the wood. Or not, if the surface is fully saturated. All this is the flip side of lumber drying processes.”

I have sent an e-mail to Bill Rose. I hope that he can respond to some of your specific challenges.

Good comment

Martin Holladay just drew attention to your comment.

I went to your http://www.ncdc.noaa.gov/oa/climate/online/ccd/avgrh.html reference, and the data do indeed support your claim that my contention of high RH during winters is questionable. Very interesting. This table gives the monthly average over several years of RH measurements taken at one time in the morning and one time in the afternoon. The notes explain which hours are selected. The hour selection is reasonable for the various zones.

I use a different NOAA dataset for my research. http://www.esrl.noaa.gov/gmd/grad/surfrad/aveform.html This is data from SURFRAD, and it has several benefits: 1) it includes radiation measurements, and 2) one of the sites (Bondville) is maintained by colleagues in my unit. The URL here allows a user to see the average monthly RH for a given year, where the average RH is the average of all RH measurements taken during the month, for a given year. These results for a site like Bondville paint a picture very much in support of my contention of high RH (80s) during winter and lower RH (50s) during summer. Southern states do not follow this pattern, but the northern-climate bias of building researchers is legendary.

So our differences on this matter come down to interpretation of available data. I am appreciative for the data you cited, and I’ll pipe down until I’m comfortable with a resolution of this.

On another matter you quote me correctly: "At the same vapor pressure, lower temperatures means higher relative humidity and higher moisture content." The moisture content I refer to here is the moisture content of materials that hold water, that are porous and hygroscopic, like wood. The RH/moisture content relation is captured in the sorption isotherm. http://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr190/chapter_04.pdf

Looking back, it was not clear in my comment that I was referring to materials. Given these two clarifications — different datasets and a strict meaning of “moisture content” — I think I can stand behind my comments in light of your challenge. There are other matters you raise. I’ll respond if and when I can. Keeping it short… Thanks for the close reading.

Interesting Topic--

From discussions here, this is my understanding regarding this topic of wall moisture originating with exterior hygroscopic materials being chilled during winter. I just wanted to lay this out to make sure we are all on the same page. It is an interesting topic.

As the average temperature drops from summer levels to winter levels, wood siding, sheathing, and the outer portions of studs will adsorb/absorb more moisture due to the temperature drop. What matters is that the colder wood can hold more moisture, so it will take it on from whatever source is available. And even if wintertime RH may be lower than that of summertime, it will be often high enough to provide a source of moisture adsorption of the colder siding, sheathing, and outer part of the studs.

Then, if the wall cavity is insulated with permeable insulation, the warmer areas toward the interior will cause drying of the extra moisture that has been acquired by the siding, sheathing, and outer parts of the studs. And as that moisture dries inward, it amounts to an inward vapor drive. As the siding, sheathing, and outer parts of the studs dry inward, they continue to take on more moisture due to their relatively lower temperature at the far exterior. So, you have a continuous pumping action that creates an inward vapor drive.

There is also an outward vapor drive due to diffusion. So these two opposing vapor drives meet somewhere within the wall cavity. This raises the question of which drive is dominant. If the inward drive were strong enough, it might totally cancel outward vapor drive. Indeed, if the inward driver were strong enough, it might just continue all the way through the wall and dry to the interior.

So, the inward vapor drive is originating from the siding, sheathing, and outer parts of the studs, all of which are acting as accumulator / reservoirs to hold an increasing moisture content due to adsorption brought on by falling temperature. And then, from that collecting reservoir, the moisture diffuses inward.

As that outer moisture begins its inward diffusion journey, it starts out already on the condensing side of the dew point in the wall.

However, according to Joe Lstiburek, the inward diffusion would not condense at the dew point. Instead, it will move on to a “condensing surface of interest” (a preferential nucleation site), which will be the inner wall surface.

But when this inward diffusion collides with the outward diffusion, it makes me wonder what nucleation site will be preferred. I guess it depends on which drive is stronger. Since a large number of insulated buildings were found to have wintertime frost on the interior side of the sheathing; and if this was not due to outward diffusion; then it seems as though this inward drive mechanism is quite strong compared to the outward diffusion drive.

summer drying

Martin said:

"Second, since an interior polyethylene vapor barrier prevents wall assemblies from drying inward during the summer, a layer of poly can actually make the wall wetter than it would be without the poly."

I think its worth framing that comment in the context of air-conditioning, or no air-conditioning, even though americans almost alway have/want AC.

If there is no AC then a wall cavity is not going to dry any more to inside than outside.

Climate Zone?

Martin, you referred to climate zones a number of times. Which climate zones are you referring to. Could you post a link to a map with those climate zones? Thx

Response to Gregory La Vardera

Gregory,

You're right that if a house is air conditioned, the indoor air will be dryer than if the house has no air conditioning.

But even in a house without air conditioning, there are many hours during the summer when the indoor air might be dry enough to encourage inward drying of a wall -- for example, during the morning hours, if the indoor air of the house has been cooled by the nighttime operation of a whole-house fan.

Weather conditions change, and the indoor air may be dry and cool under some conditions -- and omitting polyethylene allows the wall assembly to dry inward when conditions are right. If the polyethylene is there, the inward drying will never occur.

Response to Marcus de la Fleur

Marcus,

The DOE climate zone map can be found on our Q&A page:

https://www.greenbuildingadvisor.com/qa

Click the small image to enlarge the map.

I will also post the map here.

.

Summer Drying

Martin, I appreciate your thoughts on this, although I find the prospect of limited morning or overnight drying in a house without AC to be a very slim benefit. I'm guessing this is more of a hunch than science?

If you live in a climate cold enough that you would not have AC - although I somehow doubt americans in any zone would be without AC - but if you were without AC you would do much better by keeping your poly and simply making your wall system more open to the exterior - building paper instead of housewrap, plywood instead of OSB.

Add'l response to Derek Roff

You point out that observations from the 1930s were poorly documented. That’s correct. My effort has been to capture what documentation we do have and draw appropriate conclusions from that. See http://www.astm.org/DIGITAL_LIBRARY/JOURNALS/TESTEVAL/PAGES/JTE102972.htm (not free).

We seem to agree on the fundamentals. At equilibrium, the temperatures and vapor pressures will determine the moisture content. Warming tends to dry materials, and conversely cooling tends to wet them. You note that siding is in the outward heat flow path, so the siding should receive some drying benefit from that. True, and with the introduction of insulation in the 30s that benefit got reduced.

I admitted to being a bit flummoxed by the monthly average RH data you cited at http://www.ncdc.noaa.gov/oa/climate/online/ccd/avgrh.html . I looked more closely at this data, particularly in the northern states. You note a peak in August-September. This is true for the average of all sites. For northern states, it is a sub-peak, lower than the peak in December-January. The trough for all sites is April-May. More to the point, the averages do not represent a wide span—mid 70s at the peaks, mid 60s in the troughs, which is narrower than I’d taken from my data source. It is commonplace to recognize wetter exterior materials during winter and drier materials during summer. The span in seasonal RH data does not explain the wider range in moisture content data. Adding radiation to the equation gets us there.

You seem to suggest that the quality of data, research and explanation is not really up to the level of what can be called physics. Perhaps you’re right. We do what we can.

Response to Gregory La Vardera

Gregory,

Your advice is risky, for the simple reason that no builder can assume that, for the life of the building, no one will ever install an air conditioner.

Especially with the prospect of global climate change, it's hard to imagine that many builders would make such a risky bet.

Thanks to Bill Rose, it's great to learn more.

I appreciate your response, Bill. I will try to read through the references that you provided, and understand these concepts more completely. In the meantime, one of the central points that we are discussing remains confusing to me. If I'm understanding what you just posted, you are saying that as you cool water-absorbing materials, such as wood siding, the moisture content goes up. Looking at Table 4-2, at the top of page 4 of the Forest Products Laboratory link that you provided, I see that the variation is tiny. For example, at 80% relative humidity, moisture content of wood at 50 degrees F is listed as 16.4%. When the temperature drops to 30 degrees F, the equilibrium moisture content is 16.5%. At 95% relative humidity, and at 5%, there is no difference at all in the listed figures over that temperature range. In fact, half the listed values show no change, while the other half show a difference of 0.1%. These differences seem very small to me. What am I misunderstanding?

Response to Derek Roff

At the same RH, temperature differences mean practically nothing to the moisture content of wood. At the same outdoor vapor pressure (or absolute humidity), temperature differences lead to differences in RH thus to much larger changes in moisture content. Two houses side-by-side, during cold weather will be subject to the same vapor pressure. Warmer siding will be drier than cooler, surrounded by the same vapor pressure.

More questions for Bill

Thanks for clarifying, Bill. What is the range of temperatures that you would expect for the siding in model/example side-by-side homes, with differing amounts of insulation?

more response

Not much. A few degrees, maybe 3-5F. An IR scan would show differences in temperature house-to-house and at the same house.

Slight lowering of temperature leads to slight moisture effects. It's usually not a problem except where the cladding is not robust. There are many buildings and building parts that receive no vagrant heat, so they can be viewed as limiting cases for how bad it can get. Garages, porches, overhangs, etc. whatever works in these conditions works just fine in superinsulated buildings. We've seen a 19% loss in compressive strength in marble cladding between the surfaces that receive significant vagrant heat compared to those that do not, in a monumental NY building. The vagrant-heated marble had the same strength as marble warehoused at the source quarry, after 60 years. Can't identify the building, sorry. Just to say that in most situations the impact of added insulation can be ignored, but there are some cases where it cannot.

Summer Drying Risk

Martin, I think that is a strange picture of risk. If the person building the home does not have AC it would be more risky to use a wall assembly that would not perform as well for their use. What you are suggesting is accommodating an unknown future owner over the current owner.

You want to alleviate the risk of a future owner who may install AC without looking at the composition of the wall?

Response to Gregory La Vardera

Gregory,

If a wall assembly is so risky that the installation of an air conditioner would push the wall into failure, then I certainly wouldn't want to build it.

Risky wall assembly

But what you are saying now would preclude a vapor barrier in any situation. You are contradicting your statement here:

"In a very cold climates (the colder sections of Climate Zone 7, as well as Climate Zone 8), the traditional use of interior polyethylene vapor barriers is often beneficial."

Response to Gregory La Vardera

Gregory,

Just because a polyethylene vapor barrier can be beneficial in a certain type of house -- one that has no air conditioner -- doesn't mean that it's wise for a builder to install one. A wall has to be robust to keep a builder out of trouble. No builder wants a wet-wall problem, and no builder wants to be sued.

It is highly likely that any home in the US and southern Canada will have air conditioning at some point over the next 40 or 50 years.

So, if you live in Minnesota or Quebec, using MemBrain makes more sense than using polyethylene.

Lots of interesting comments on this thread

Thank you Ron Keagle and others for asking questions.

Risky wall assembly

Martin, enough. I understand what you saying. I am just trying to extrapolate that to its limits, or at least provoke you into identifying its limits.

So if you are north of southern Canada you are now suggesting that a wall assembly with Poly as I have described may be appropriate? But somebody can certainly decide to install air conditioning in those regions, invoking your "risk". But you are ok with that risk in those regions? Its no longer:

"If a wall assembly is so risky that the installation of an air conditioner would push the wall into failure, then I certainly wouldn't want to build it."

Really Martin, I don't expect you to continue to respond to this, because the point is the circle of reasoning you've outlined. You've said both "this is ok where there is likely no AC", AND you've said "NO wall that can be defeated by AC is OK". This can not be reconciled. I would not beat this to death if you did not characterize my advice as "risky", but you really left me no choice. I'll state my case, and then we can let it drop.

If you are building a house without air conditioning whether in northern canada, or in zones 5&6 right here in the US you would be better served by a wall assembly with Poly and a bias to being open to the exterior, than you would be by the interior drying, or both side drying assemblies loosely referred to in this post. It will have superior performance during the heating seasons, and no penalty for summer drying. In fact such walls are used widely throughout scandinavia, and I really have no idea how in the US we have such hubris to think we know better.

If somebody at some future date decides to retrofit a house, any house, with AC it would be very RISKY for them to do so without making a proper and appropriate investigation as to the composition of that wall, and to change it if need be. Let us please recognize where the risk really resides. No builder will take on risk and liability for building a proper wall for a house without a cooling system.

All that said it is no more effort to build such a wall with a smart vapor sheet than Poly, and so I can't imagine why anybody would not do so. Really the whole issue is moot, as is this strange sense of risk. Not because the Polyethylene boogie man that has been a popular green building science theme, but because its a better product and does a better job. Period.

Truly Martin, I think you create much more risk with the rather casual recommendation for the elimination of vapor retarders and you seem to have little worry over that. This advice is taken up by builders with no idea of making the wall air-tight, and no idea of the potential failure they may be inviting. If you are concerned with Risk, you should think about making your message more clear about the necessity for airtightness if you actually go down the road of no vapor retarder. I can assure that broad misunderstandings are already coming back to practitioners such as myself, many telling me that they read about it here. Many of them are bound to end up on the lower half of that clever BSC diagram with 30 qts of water in their wall. Whose risk is this?

Response to Gregory La Vardera

Gregory,

Houses differ. While most Canadian houses with poly are doing just fine, a few aren't. There are lots of variables: what's the siding? what's the sheathing? what's the rainfall? what's the indoor RH? how cold does it get? is there AC?

WUFI does a fairly good job of analyzing these factors, if the program is used by an experienced practitioner. Otherwise, most builders need to use rules of thumb.

In my writing, I do my best to provide useful rules of thumb. I don't want the typical Canadian homeowner with poly in their walls to worry. Most of these walls are fine. But just because these walls are fine, doesn't mean that a new home builder would choose to build a wall that way if he had a choice.

rules of thumb

Martin, I could not agree with you more, that the vast majority of houses get built using rules of thumb. We all know that 99.99% of houses will never see a WUFI analysis.

In that context it seems that a wall assembly that is open to dry to the inside, and relies on exterior foam insulation to keep the dew point outside the cavity is vastly more likely to have its performance altered by local weather conditions, material choices, out of design range temperatures, out of design range humidity levels - all things that could be examined and resolved with analysis, that we all acknowledge they will never get.

What I am saying is that it appears there is far more risk in these type of walls we see green building experts steer people towards. There does not seem to be much concern over that risk. I just think you are contradicting yourself, in the way you've discussed the wall with poly here. You are using risk as an excuse while clearly not concered about greater risks in other assemblies you recommend. Thats the point I want to make, so I'm done. You are welcome to the last word on this.

Response to Gregory La Vardera

Gregory,

I'm interested in dialogue -- not having the last word. Your input is valuable.

Like most builders, designers, and researchers, I had my doubts about the use of exterior rigid foam in the late 1970s, and wondered whether this method of building was risky. Nevertheless, when I built the house I'm living in now in 1981, I took a leap of faith and installed a layer of rigid foam on the exterior side of my sheathing.

Since then, I've had a few opportunities to open up my walls. Fortunately, they are dry as a bone.

I'm aware that my house is an example of an anecdote, not data. However, over the past few decades, I've also had many opportunities to review research papers on these issues. Every year, the evidence keeps accumulating that walls sheathed with exterior foam of adequate thickness perform extremely well, and stay remarkably dry.

In recent years, good data have been coming out of the Coquitlam test hut in British Columbia. (See, for example, "The Coquitlam Experience".)

It's fine to be skeptical, Gregory. I share your skepticism. However, eventually skepticism must yield to data.

data vs skepticism

There is not a drop of skepticism in my opinions Martin. Painting them as such makes them seem less valid, so lets invalidate that first. The cautions I expressed in my previous post are based on building science principals that are obvious. Clearly a wall with exterior foam can be designed well and can operate well. My concerns are that it can more easily fail, particularly when we go by rules of thumb.

For many years we have had good reason to look to exterior foam as a strategy. Continuous layers of exterior insulation is one of the best ways to improve performance of an assembly. But because of the properties of foam it necessitated this flip to the previous consensus on the vapor profile. I think we are beyond that now and better alternatives to foam are readily available. Rigid mineral wool, and affordable double stud assemblies make the necessity to flip the vapor profile moot.

What is disturbing is that it is never framed as an aside - "here is something you should do if you are going to use exterior foam". Instead this flipped vapor profile is now offered up as the preferred solution. It does not perform better, it does not cost less. Why would this be the predominant advice?

Response to Gregory La Vardera

Gregory,

You misunderstand: this isn't about rigid foam.

The homes built by Zaring Homes that failed due to inward solar vapor drive did not have exterior foam. (If they had, they would still be standing.) But they had interior poly.

Polyethylene contributed to the EIFS failures in North Carolina, as well as the "leaky condo" failures in British Columbia. Most of the British Columbia condos did not have exterior rigid foam.

I'm not suggesting that builders "flip" anything. I'm suggesting (a) a greater focus on air tightness, and (b) an understanding of the role of vapor diffusion in wall asemblies. (Hint: the role is minor.)

Even back in the 1980s, Canadian builders began to realize that poly wasn't really needed as a "vapor barrier." That's why R-2000 builders started to call it an "air/vapor barrier."

Now we can achieve good air tightness with gypsum wallboard, plywood, or OSB, so we don't have to use poly as an air barrier. As a result, our walls are more robust, and less likely to fail.

misunderstanding

I'm not familiar with the Zaring Homes example so that point is lost on me.

Listen, I'm not pushing for poly, and I'm not pushing for foam. But if you want to posture that these walls are robust, at least the foam moves the dew point out of the cavity most of the time. Without that what has our rule of thumb boiled down to? Tape up the outside, caulk up the inside?

Taped sheathing vs house wrap, gyp board vs air tight gyp board. It seems very little has changed, certainly not enough to refer to such an assembly as "robust". You advise to forget about the vapor retarder is really not all that different than the way walls have been and are being made. Kraft retarders on fiberglass never made an air seal, and likely never made a vapor seal either. Then all that has changed is your light advice that "it’s always a good idea to include an interior air barrier". So we caulk the electrical boxes, maybe. Did we get every hole, every seam in that metal box? Were the electricians wires in the way? Ehh, that will do.

Do we have "robust" wall, or do we have 30qts of water heading into the cavity?

This is not a robust assembly, and we as a green building "movement" are kidding ourselves and an ignorant housing industry if we continue to present it as such.

The answer to the question your blog post is about is "No, you don't need a vapor retarder, if you tape, and caulk, and caulk some more. But if you want to build a robust wall system with the best performance you want to use a smart vapor control layer, and keep your wiring inboard of that sheet to minimize penetrations. Its no harder to build, it costs about the same, and its hard to imagine why you would not opt for the better solution.

Response to Gregory La Vardera

Gregory,

For more on the Zaring Homes fiasco, see When Sunshine Drives Moisture Into Walls.

You wrote, "What has our rule of thumb boiled down to? Tape up the outside, caulk up the inside?"

Greg, your proposed rules for air sealing are insufficient, and they don't represent my advice. We probably agree on air sealing rules of thumb. It's more than just "tape up the outside, caulk up the inside." I imagine that you and I would give the same advice to any builder: pay attention to your air barrier everywhere, with particular attention to penetrations, material seams, and changes in building materials. Then verify the performance of your air barrier with a blower-door test, and seal up any leaks that the blower door reveals. (If you think that I have a laissez-faire attitude toward air sealing, you might want to read Questions and Answers About Air Barriers.)

I think that even a cursory reading of my articles here at GBA will verify that you are providing a thin parody of my recommendations when you write that I provide "light advice that 'it’s always a good idea to include an interior air barrier.'"

Here's the thing, though: you have to pay attention to air sealing details whether or not you install interior polyethylene. The polyethylene argument really has nothing to do with the question of air sealing details.

Do you know the old Buddhist saying: "Before enlightenment, chop wood and haul water. After enlightenment, chop wood and haul water"? Well, we can reformulate that saying: "With polyethylene, pay attention to air sealing. Without polyethylene, pay attention to air sealing."

We both want robust wall assemblies. There is no substitute for careful thought, study, and execution of details if we want a robust wall assembly. It's not just about where you put the rigid foam, or whether or not you have poly. We need whole-house thinking. Everything matters: your choice of sheathing, whether or not you have a rainscreen gap, your roof overhangs, your flashing details, your penetration details, and the permeance of your interior finish materials. It all matters.

comments are based on your post

Martin, my comments, and parody if you wish, was simply based on the content of your post above. The same thing a builder inexperienced with raising performance would read if they landed here after a google search for "vapor retarders".

If you are saying its not about one kind of material or another, then you are not being earnest. The only thing that drives me to even comment here is the repeated advice for what I consider to be low quality, failure vulnerable assemblies. I don't think there is any self awareness or perspective here on suggestions like "air tight' drywall, the prospect of suggesting to a builder that they seal the gaps around each receptacle and switch box, that they seal every hole and seam in an electrical box.

Perhaps the green building community has just become too secular, too immersed in a community that all agree with one another. Used to speaking with people who care, and no clue how to propose solutions that can be implemented by people who really don't care.

This gets back to your distorted sense of risk. Those people who don't care, sure they can be compelled to seal all that electrical work, but they will never do a good job at it. If your advice is to be a model widely adopted in the housing industry, you will inevitably have walls built with lots of leaks, and 30qts and more of water heading into your cavity. If you don't' believe me, just look at fiberglass batts. Same problem. Its not that you can't do it, its not that its so hard to do, its that its just so much more profitable to do a lousy job. Your airtight drywall is the same thing in a different suit. This is not a robust solution, and it will not lead to a robust assembly.

Its just lamentable that this is the advice handed out so often here.

Response to Gregory La Vardera

Gregory,

You say that the average builder does a bad job of air sealing. I agree.

You say that journalists (like me) who write about building science issues should remind builders of the importance of air sealing. I agree.

Here's where I disagree: I disagree with your conclusion that "Its just lamentable that this is the advice handed out so often here."

In fact, I think that GBA is doing a pretty good job helping to educate builders about the importance of air sealing, and suggesting methods to reduce air leakage. I could create a list of articles in this post to prove my point, but you could find the articles easily by using the GBA search box and searching for "air sealing" or "air barrier."

You believe that the Airtight Drywall Approach is hard to do well. You may be right. It's also possible to create an air barrier at the wall sheathing and roof sheathing, as Marc Rosenbaum suggests. It's also possible to use both techniques. Every time a North American builder says, "These techniques are just too hard," the European builders who are building Passivhaus buildings scoff, "It's not hard! We do it routinely."

Look, I'm happy to listen to your feedback. You tell me that GBA is doing a lousy job explaining air sealing details to builders. I'll take it to heart and try to do better, because my goal is the same as yours: to help builders build better buildings.

Finally, I'd like to remind you that installing a layer of polyethylene on your walls doesn't solve the problem of air leaks. Builders who use interior poly still need to study air sealing.

let me restate my point

I'm not saying that GBA is doing a bad job advising people to do air sealing. I'm saying that if you are concerned about risk - which you claimed you were - then the advice (or lack of in this particular post) you are giving out about air sealing could be seen as risky. I'm using airtight drywall as an example of that.

This is all playing off your criticism of my advice to use poly in a wall with no AC - you called it risky. While in the same article you acknowledged that use of poly could be beneficial, and in the comments you were basically saying its always risky, you should never use it. I'm flagging that - contradiction.

And I've strayed from the primary question of poly into air sealing because I'm pointing out that generally your concern about poly as a risk compared to your lack of concern about airtight drywall as a risk also seems like a contradiction.

I'm not out to make some site-wide criticism of GBA here. If I am saying you were casual about reinforcing No Vapor Retarder with Must Air Seal, its because in this post it was treated very casually. Elsewhere on GBA it may not be so.

Using a sheet based vapor control layer does not solve anything by itself. Put it right behind the drywall, and you have a world of sealing problems. But its far easier to move the wiring in front of the sheet making all the penetrations go away, than it is go back and caulk every hole you can find in your drywall and electrical boxes.

Response to Gregory La Vardera

Gregory,

It seems that you are raising a new topic, but that's fine. You're saying that we shouldn't discuss the Airtight Drywall Approach, because it is risky.

That raises an interesting question. I would reply that it's only risky if builders do a sloppy job. But I think you are saying that the chances are so high that builders will do a sloppy job that the entire approach shouldn't be recommended.

That's a valid point -- kind of analogous to my opinion about fiberglass batts. (It's my contention that installing fiberglass batts according to the manufacturers' instructions is so difficult that the entire method of insulation is risky.) I agree that we need to promote methods that work in the real world.

However, saying that the Airtight Drywall Approach is risky because many workers fail to do a good job is a little different from saying that Zaring Homes' use of polyethylene was risky. As installed in the Ohio homes built by Zaring, polyethylene contributed to failure, even though it was installed correctly. It pushed the wall assembly over the cliff.

It's certainly worth discussing which wall assembly types are easiest to build and most robust. This article -- the one on vapor retarders -- isn't really about the Airtight Drywall Approach. If a builder follows the guidelines in this article, the guidelines will work for a wall with the air barrier at the sheathing level. They will work for a double-stud wall. They will work for a foam-sheathed wall. They will even work for a 2x6 wall filled with fiberglass batts, as long as the builder pays attention to air sealing -- which in most cases requires verification with a blower door.

If you are verifying your air barrier with a blower door, and tracking down wayward air leaks when the blower door is operating, I don't really care where you put your air barrier.

Question

Martin,

You said this:

"Finally, I'd like to remind you that installing a layer of polyethylene on your walls doesn't solve the problem of air leaks. Builders who use interior poly still need to study air sealing.”

I do not follow your point. If you are saying that a defective vapor barrier does not stop air leaks, then yes I agree. But a continuous poly vapor barrier with all seems properly sealed with no leaks, and no field damage will certainly stop all air leaks. It can’t be a vapor barrier if it has air leaks.

It can, however, be a layer of polyethylene, as you stipulate. And if that is thrown up with staple damage, unlapped seams, sloppy taping (if any), unsealed penetrations, and subsequent drywalling damage; then I agree that it does not solve the problem of air leaks.

Response to Ron Keagle

Ron,

You wrote that a poly vapor barrier "can't be a vapor barrier if it has air leaks."

Actually, it can. Joe Lsitburek makes this point often. You are confusing diffusion with air leakage.

If a layer of polyethylene sheeting has holes in it so that it is 97% polyethylene and 3% holes, it will be worthless as an air barrier. But it will still be 97% effective at reducing the flow of water vapor by diffusion. So it's a vapor barrier, not an air barrier.

I've seen many, many homes with interior polyethylene. I have not yet seen any installations of polyethylene that qualify as an air barrier. They all leak.

But if you are conscientious, it is possible to install polytheylene as an air barrier. It's incredibly fussy and difficult work. (It probably falls into the category that Gregory La Vardera would refer to as "so difficult to do that it is risky to recommend.") I've read about a few builders who have done it -- some in Canada, including a few pioneers of the R-2000 movement in Saskatchewan, and at least one builder in Wisconsin, Steve Lentz.

To install polyethylene as an air barrier;

1. You need to install airtight electrical boxes.

2. You need to find a way to seal all of the electrical boxes to the poly.

3. You need to be sure every polyethylene seam falls over a framing member.

4. You need to seal every polyethylene seam with Tremco acoustical sealant.

5. You need to find a way to bridge the gap between the poly and the window frames. (Steve Lentz follows a complicated procedure that includes installing a polyethylene "bib" around each window before it is installed.)

6. You need to create details to bridge the air barrier gap between the concrete foundation and the wall poly.

7. You need to anticipate interruptions of the ceiling air barrier that occur when top-floor partitions are installed.

It's possible, but it's a lot of work. Probably more than A.D.A.

Diffusion vs. Air Leaks

Martin,

I am not confusing diffusion with air leakage. I fully understand both principles and know the difference.

You said:

“If a layer of polyethylene sheeting has holes in it so that it is 97% polyethylene and 3% holes, it will be worthless as an air barrier. But it will still be 97% effective at reducing the flow of water vapor by diffusion. So it's a vapor barrier, not an air barrier.”

I don’t understand your point. If the poly sheet has 3% holes, it is a defective vapor barrier. Furthermore, how could a poly barrier with 3% holes be a worthless air barrier, but be a 97% effective diffusion barrier? How do you conclude that 3% holes renders it "worthless" as an air barrier?

You said:

“I've seen many, many homes with interior polyethylene. I have not yet seen any installations of polyethylene that qualify as an air barrier. They all leak.”

I have seen a lot of those too. But again, I would never equate the mere existence of “interior polyethylene” with an adequately executed vapor barrier. Interior poly could be an adequately executed vapor barrier, but not if it leaks.

I understand all your points about the difficulty of executing a perfect vapor barrier. I believe that the vapor barrier and its sealing members must be carefully designed, particularly as it pertains to the window and door tunnels. I would put the electrical boxes and cabling in their own service cavity in order to eliminate the need so seal the vapor barrier around them.

I agree that it would be very difficult to execute a perfect vapor barrier in just any arbitrary architectural design. My consideration of this issue is only for new construction, superinsulated houses where the architecture is idealized for the superinsulation principles.

Response to Ron Keagle

Ron,

You wrote, "I understand all your points about the difficulty of executing a perfect vapor barrier."

No, you don't -- because a vapor barrier doesn't have to be perfect. It can be quite sloppy, and still work fine.

We can measure diffusion in a lab. For example, if you paint 90% of a piece of gypsum drywall with vapor retarder paint, but leave 10% of the gypsum drywall unpainted, then the vapor retarder will be 90% as effective as a vapor retarder covering 100% of the gypsum drywall. The reduction in diffusion can be measured.

Perhaps it's easier to understand if you imagine a vapor barrier under a concrete slab. Let's say you put down a layer of 6-mil poly, but the poly is in terrible shape. It's full of holes. Maybe 5% of the poly is totally gone -- just plain missing. This sloppy vapor retarder will be 95% effective. The reduction in diffusion can be measured in a lab.

You can't be that sloppy with an air barrier. Huge amounts of air through small holes, especially if there is a driving force (for example, the stack effect).

Response to Martin

Martin,

Thanks for that explanation. Just to be clear, when I say "perfect" vapor barrier, I mean one that works just fine.

My question was mostly directed to your comment about how 3% holes in the vapor barrier would render it worthless as an air barrier. I am just wondering generally what you mean by these terms.

I understand your point about a lot of air escaping through small holes, but wonder how this correlates to the complete loss of air barrier function that you mentioned. I would think that holes in the air barrier would gradually degrade its function, just as would holes in the vapor barrier. The degradation would not perfectly match, but the general trend would be the same.

Response to Ron Keagle

Ron,

You wrote, "I would think that holes in the air barrier would gradually degrade its function, just as would holes in the vapor barrier."

You're right, of course. But here's the thing: let's say that an earthquake or a tornado suddenly removes 10% of your walls and ceilings. Only 90% of the walls and ceiling remain. The wind is whipping through those holes.

As you can imagine, your house has become unheatable. There's no way your furnace can keep up. All of your heat is leaving the house through the huge holes created by the earthquake or the tornado.

That's very different from a situation where 10% of the vapor barrier is missing from underneath a concrete slab. The remaining 90% vapor barrier is adequate to reduce the vapor diffusion through the slab. No one notices the 10% problem.

So when does an air barrier become "useless"? With 0.1% holes? With 1% holes? With 3% holes?

I guess it depends on your airtightness goals. But if I install gypsum wallboard as my air barrier, I wouldn't want a 1 square foot hole in each sheet of drywall. (That's what a 3% defect in my air barrier means.)

Great Article

Great Article Martin. I read your posts but never seem to comment. Just wanted to thank you for your thoughtful blogging! I especially love the "Executive Summary" at the bottom. I do alot or whole house remodels in hot/humid Austin TX and I've seen firsthand the mold growing behind the poly sheeting of 90's houses I've remodeled. Attached is a photo of a 1995 built home I remodeled last year with mold behind the vapor barrier. Best, Matt Risinger

Response to Matt Risinger

Matt,

Thanks for the feedback, and thanks for sharing the photo. I wasn't aware that polyethylene stupidity reached as far south as Austin, Texas.

Tiny House Vapor issues

Thank you for the very informative articles, Martin. They are very useful.