Image Credit: National Renewable Energy Laboratory

Ben Rush likes the idea of a ground-source heat pump, despite their reputation for higher cost than other heating and cooling alternatives.

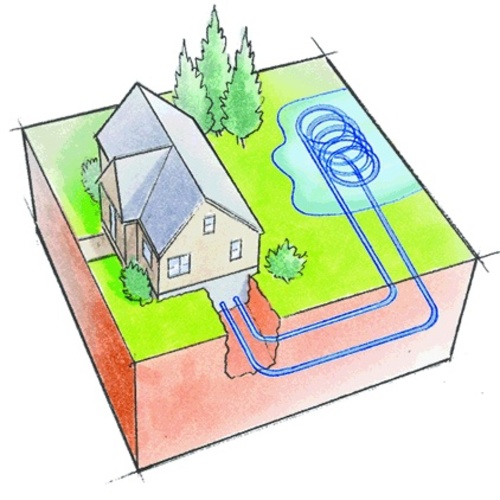

A ground-source heat pump (GSHPs) requires heat-exchange tubing buried in the ground or inserted in a well or pond. The excavation required to bury the lines (or drill an extra well or two) helps to make GSHPs more expensive than air-source units. In addition, the equipment itself tends to be more costly. In all, GSHPs suffer a significant disadvantage when it comes to cost.

Even so, Rush thinks they make sense, and he wonders if he’s put his finger on a way to bring down the cost of installing a new system.

“To address the first issue, could the ground loop go under a basement floor?” he asks in a Q&A post at GreenBuildingAdvisor. “Would any additional excavation be required? How much? Would 2 or 3 inches of sub-slab foam insulation be enough to separate the conditioned basement from the year-round +/-55F (Climate Zone 5) soil? Bottom line: would this be an inexpensive — yet effective — way to install the ground loop?

“I really like the idea of GSHPs,” he continues, “for two theoretical reasons, and one practical one: A) In zone 5, the soil is cooler than the air in summer — and warmer than the air in winter. Why would I want to put heat into 90° F. air or take heat out of 10° F. air? B) The volumetric heat capacity of soil is about 1000 times that of air; and C) in Chicago, occasionally it might be too cold to heat with a minisplit (not sure if that’s three times a year — or once every three years — but it could happen), but it will never be too cold to heat…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

11 Comments

In the process of installing. Tax credit was the difference

I am currently having a geothermal system installed in North Carolina. We are using the waterfurnace 7 series. This was a full remodel, with all new ductwork as well. We used the horizontal boring method, as we had room on the property. It was amazing how they bored horizontally and combined the pipes in a header pit, and then brought them to the variable speed pumps and the units. The federal tax credit made the difference. I had 4 real world quotes for top of the line air source heat pump systems, and net of the tax credit the geothermal was actually cheaper to install. So if the ground source is cheaper to operate, I am ahead of the game. Also nice not to have noisy units outside, and trying to figure out the benefit of the desuperheaters for hot water as well.

Thanks to Dean Sandbo

Thanks for your report. I am pleased to hear that you have what should be an excellent system at a reasonable net cost. If you are willing to share details of the cost and size, that would be interesting to many here.

air seal and insulate

Our midwest home, directly west of Chicago, with hot humid summers and snowy winters, is well insulated and heated with a portable air source heat pump. A Friedrich bought on sale under $300.

It is amazing the gyrations people will go through for bragging rights.

Air seal and insulate. Eat plants.

Geo in Chicago

We are leading energy consultants in Chicago, and I want to say thank you for laying out and supporting a repeated discussion I have with clients. On historic residential retrofits, geothermal may make sense. On commercial buildings, maybe worth evaluating. But if you are doing a gut rehab or new construction single home, we find it often isn't worth it.

It will be great to now have this resource to point single-family homeowners to, and save my breath for discussing high-performance enclosures. Thanks again!

The importance of load calculations.

The importance of accurate load calculations goes WAY up when considering a mechanical solution as expensive as a ground source heat pump (GSHP). There is usually quite a bit of low(er) hanging fruit on thermal retrofitting of existing houses that are more cost effective too.

In dean sandbo's North Carolina, a state of the art right-sized modulating air source heat pump can hit pretty close to average GSHP system efficiency, with lower system design risk.

The 30% Federal Income Tax subsidy that was extended for many efficiency & renewable energy measures late last year was NOT extended for GSHP systems. That subsidy will end at midnight on 31 December 2016. After that the industry has to fly on it's own (or state & local subsidies), but I'm not too hopeful that it will be as cost effective as air source heat pumps + rooftop solar by the time the solar subsidies also dry up completely in 2022. Solar is becoming dramatically cheaper year-on-year, and air source heat pumps continue to improve incrementally with every model release.

In my area (southern New England) GSHP systems cost ~ $9000/ton (before subsidy) installed, high efficiency ductless costs ~$3.5-4K/ ton installed. At the current local pricing of $3-3.25/watt for PV the $6-6.5K difference buys about 2000 watts of rooftop PV, that delivers ~2300-2500 kwh of AC electricity every year. A typical 2500' house would take 2- 2.5 tons of ductless to heat & cool the place, and even assuming the total output of the PV is only 2000 kwh/year due to unfavorable shading factors, the 4000-5000kwh of electricity would cover well over half of the heating power use, even at a paltry HPSF of 10, , far more than the difference in power use between GSHP and ductless. (The best in class ductless units test in the HSPF 13-14 range, and would pretty much cover all of the power use.)

Before 2020 the installed price of solar will be under $1.50/watt, unless there is severe canges in Federal and state policy support. It's already that cheap in Australia (~USD$1.26 /watt in a 2016 survey of small scale rooftop systems), using the same panels, inverters, & racking systems used here. There is no reason it won't hit those price points in the US soon, even though the national average is more like $3.50/watt. At $1.50/watt the price difference buys 4000 watts of PV per ton, which is way more than needed to cover the entire heating & cooling energy use of the ductless heat pumps.

But there are plenty of local markets where GSHP is cheaper than it is in my neighborhood. Only time will tell if it's going to be able to successfully surf the tsunami of cheap PV in the GSHP cost markets.

IBACOS Research

For what it's worth, it looks like IBACOS researched this under Building America. If my memory is correct, they have researched both GSHP tubing below the basement slab, and in the foundation excavation around the exterior. I have only read the executive summary, not the full report.

http://www1.eere.energy.gov/buildings/publications/pdfs/building_america/heat_exchange_loop_cold.pdf

Under slab? Bad idea

Ben: Martin lists several excellent reasons why installing GSHP looping under the slab of your home is a bad idea. I'm no expert, but I can add one more, which is that the lifespan of the piping is usually set at about 25 years. I'm hoping your house will stand longer than that, and it would not be fun to bust up the basement to replace the piping.

Mike.

Thanks for that example, Kohta!

"For the 1.5-ton system installed in the cold-climate, 2,772-ft2 , two-story unoccupied test house in Pittsburgh, Pennsylvania (hereinafter referred to as the Pittsburgh Lab Home), a traditional vertical well system is expected to cost $17,800, compared to $14,000 for the horizontal sub-slab coils."

The $14K for a 1.5 ton system is $9333/ton, which is typical of recent years' per-ton costs even for systems 2-3x that size in my neighborhood.

Compared to a 1.5 ton ducted mini-split system that might costs $7000, even the cheaper version leaves $7000 on the table for rooftop solar, which at this year's unsubsidized $3.50/watt national average buys 2kw of PV, which in Pittsburgh would deliver about 2300 kwh of annual output, more than covering any difference in system efficiency.

If a 1.5 ton system fully covers the heat load at Pittsburgh's ~+5F 99% outside design temp the design load would be something like 18

,000 BTU/hr. Assuming a 65F heating/cooling balance point that's 60F heating degrees, so the house would need about 300 BTU per hour for every degree-F below the balance point. Pittsburgh average about 5700 base 65F heating degree days per year, so the average annual heating energy use wold be about 41 MMBTU.

At a COP of 1 (electric baseboards) that would take about 12,000 kwh of power use, but with a best in class GSHP with an average COP of 4.5 it would only take about 2675 kwh, and a more likely pretty-good GSHP system averaging a COP of 4 it would use about 3000 kwh.

A fairly modest efficiency ducted mini-split might only deliver an annualized COP of 2.5, which would burn through 4800 kwh, and a better class ducted system would average a COP of 3, only using 4000 kwh.

The subtracting out 2300 kwh reaped by the PV the net use of the CRUMMIER minisplit + PV is only 2500 kwh that has to be purchased, which is already less purchased power than the better class GSHP. Subtracting it from the better class mini-split yields 1700 kwh/year purchased power, which is well under that of the better class GSHP.

When rooftop PV is half the price that it currently is (which will happen well before 2025, maybe even before 2020, since it's already cheaper than that in someother first-world nations) it becomes a no-brainer, since the the difference in GSHP and mini-split heat pump cost buys enough solar to cover more than 100% of the power used by a by a better class mini-split, and over 95% of the power used by the crummier mini-split.

In short, GSHP has to get a LOT cheaper going forward to compete against mini-splits + PV (on either an annual operating cost basis, or lifecycle cost basis. ) To get there with additional subsidy would require a major increase above the 30% income tax subsidy, spending far more in just subsidy for the GSHP than it would cost to install a mini-split (unsubsidized.) Without a dramatic reduction in price/performance GSHP has no larger scale future, and will be relegated a boutique market of retrofits or commercial buildings.

(GBA, if this would be better posted elsewhere, just let me know.)

Dear Scott, Martin, Dana, Charlie, Peter, Dean, Erich, Jason, Kohta, Mike, and anyone else,

- Climate Zone 5, Chicago's western 'burbs -

Could you please recommend some architects? I recently realized that ours is not the right one for the project. (By the way- it's important that our current architect is treated fairly, respectfully, and kindly- during and after any transition.)

The project involves remodeling our 1900-ish, balloon-framed home. At some point it had been converted into two apartments. I had clumsily recombined the units into one home, but the result was a house with lots of small rooms- and a layout that just didn't work very well.

I was clear up-front that I wanted to add rigid foam insulation at the exterior (since we're replacing the roofing and siding anyway), but we focused on the interior changes first. When our attention shifted to the exterior insulation, I realized too late that our architect didn't understand or share my passion for this part of the project.

I briefly imagined that with enough research and help, I could provide him with the details and data he needs- but have since realized this won't be enough. I need someone who knows more about this than I do; not less. After it's designed, we'll have more challenges ahead of us: getting the design thru the local building dept., finding qualified subs, verifying that the details are followed carefully, and surely others.

So, can you please recommend some architects that would be a good fit?

Thank you,

Ben

Hi Ben.

You may have better luck in the Q&A forums: https://www.greenbuildingadvisor.com/qa. I don't think I have worked with any Chicago-area architects, familiar with high-performance assemblies, but if someone jumps to mind, I'll let you know.

Brian,

Will do. Thanks.

Log in or become a member to post a comment.

Sign up Log in