Image Credit: Fine Homebuilding

Eric Dymond lives in a 1920s Baltimore row house that needs a new roof. He plans on replacing the low-slope, built-up roof with an EPDM membrane, and the question is how to insulate it correctly.

Currently, the built-up asphalt roof is installed over Homasote (or something similar) and a roof deck made of wood planks. Although there’s some “sparsely distributed” insulation in the space between the ceilings and the roof deck, it won’t meet current recommendations for Dymond’s Climate Zone 4 house.

A roofing contractor has recommended that the EPDM membrane be installed over 2 in. of rigid polyisocyanurate insulation. “Does EPDM over foam board make sense?” Dymond asks in this Q&A post. “It doesn’t make sense to me to have 7 in. of foam board to meet R-38, and I’d be concerned about walking on the roof with that setup.”

In addition, Dymond is concerned that 2 in. of insulation is woefully inadequate. Would it make more sense, he asks, to eliminate the foam board recommended by the roofer and insulate beneath the roof deck with fiberglass batts or open-cell foam?

Dymond’s request for feedback and suggestions on other options is the topic for this week’s Q&A Spotlight.

EPDM over foam will work

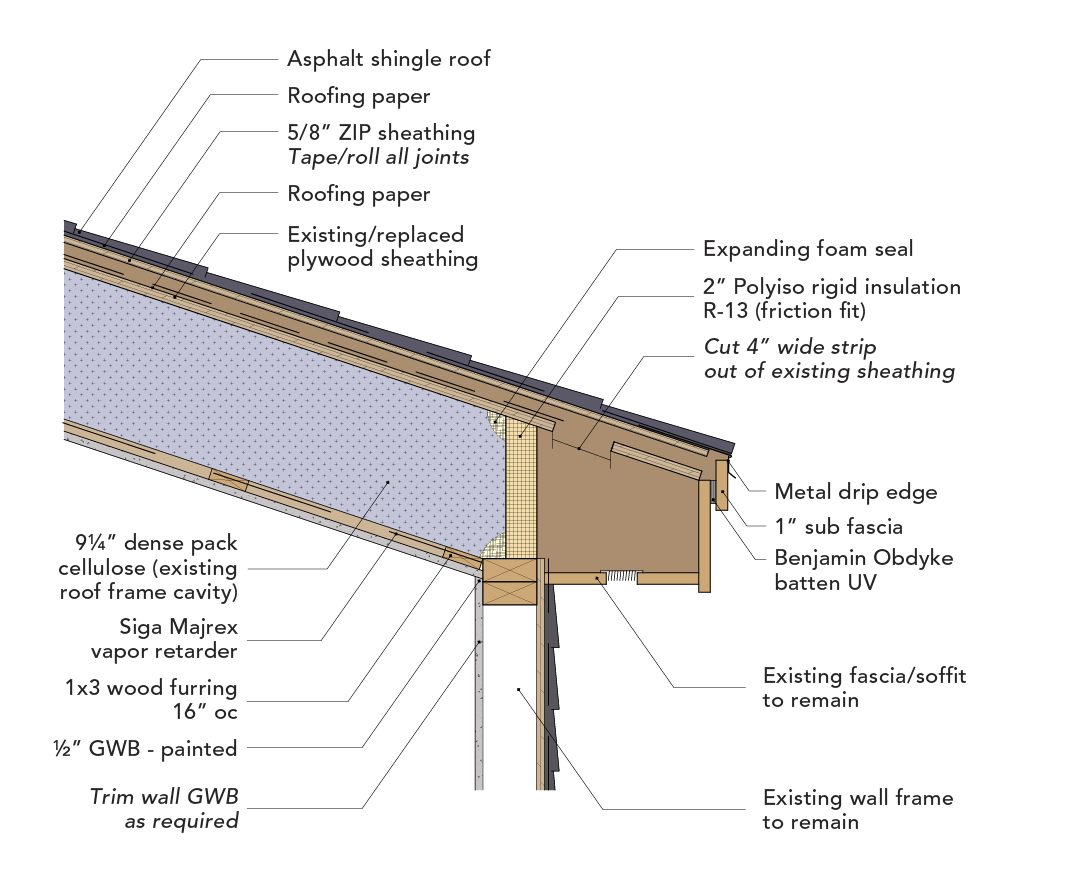

Despite Dymond’s trepidation, a roof consisting of an EPDM membrane over a thick layer of polyiso foam is common, Jesse Thompson replies.

He adds a link for Firestone roofing products, which include a number of the synthetic rubber products made from ethylene propylene diene mononer (EPDM). The company’s web site includes a number of drawings showing how the roofing should be installed.

Insulation can be installed in the attic or on top of the roof deck, says GBA senior editor Martin Holladay. The key is making sure…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

12 Comments

Thermal bypass

But if you insulate on top of the existing roof, how are you going to deal with the thermal bypass that will occur around the walls in the attic cavity where the existing batt insulation is poorly installed?

Baltimore City Codes

FYI, Baltimore City often lags in code adoption so they may be using an older code than what the state of MD has adopted.

re: Amanda

I would think insulating the walls/edges is much less complex than the whole ceiling

I think either way is

I think either way is difificult - walls or ceiling - when you can't access easily from the inside and you don't know what it in the cavity.

Also be careful insulating in existing cavities

Especially in older, existing building, insulating in wall and ceiling cavities can be a bit dangerous considering the state of some older wiring and connections. There is some talk brewing about on whether fires have occurred due to insulation around wires and insulation. If a wire is over insulated or the insulator is degraded, an arc can occur along the surface of the wire insulation, causing a fire. Note the difference between wall insulation and wire insulation in this context. Basically, if you spray or stuff insulation into a wall cavity in an existing building, pay close attention to the type and condition of the wiring that may be in the cavity. The insulation itself can burn or melt in some cases or can over insulate a wire or connection, causing a fire, which causes the structure itself to burn. Just an FYI.

And as well, the number of amps the old wire is carrying. Since lighting loads have dropped so dramatically, and high use areas get modern circuits, changes are those wires are carrying very little load, and can be protected with a smaller breaker.

Agreed - that's why it is so

Agreed - that's why it is so difficult to do and why the thermal bypass ends up being an issue if you just insulate above the roof.

Amanda is right

If you want to add insulation on top of the roof then you must also deal with the entire perimeter of the attic/roof cavity -- which is quite challenging unless you rip open / trench the roof from above or else cut an access and send in people to crawl and seal. if you are going in to crawl and seal in the roof cavity to get the perimeter, it would actually be easier to just seal the bypasses and do some dense pack in the small section in the rear that is too small to crawl. You can then blow cellulose in the rest of the cavity. This approach can be done for about $1.50/sqft -- far less than any of the foam approaches. it also leaves you with a solid roof for adding a deck.

You should perform voltage drop tests on all of the wiring that runs through the attic before and after the work and fix any problems found or created.

Amanda ususually is

If the joist space has been ventilated, as would have been proper and expected, then adding insulation above a ventilated space will provide no insulation value. Unscrupulous and/or ignorant spray foam roofing contractors in our market, of which there are many, will often tear off old built-up tar and gravel roofs and replace them with sprayed on polyiso systems. They make good roofs and provide good insulation, but not when the space below the polyiso is ventilated. These contractors make false claims to the homeowners on improved efficiency and lower energy bills. Incidentally, it is common for gravel to be placed on the foam roofs to protect them from UV degredation rather than elastomeric paint, which is only used around pipes, penetrations, flashings, etc, that the gravel does not cover. The skin of the polyiso is considered durable enough in and of itself. Most reputable roofing contractors offer 10 year warranties.

Gaco silicone liquid applied roof?

I know this is a very old thread, but in case someone else checks it out...

How about this : http://www.gacoretail.com/gacoroof.html

It's a silicone based liquid applied roofing 'coating.'

You can DIY pretty easily..

I've done it on a couple very small 'low-slope roofs'.. and so far so good (I have no long term experience with these roofs however).

In terms of insulation, I've also done a lot of blown-in cellulose installations in pitches roofs, and low-slope roofs... in really old buildings (usually are 80-100 years old).

I blew in about 10" of cellulose in my own cathedral ceiling...and has been doing well for at least the past 2 years.... I'm thinking about using Gaco coating for roof too... as I will need a new roof soon...

Anyone else have experience with Gaco coating?

-Todd

Don't forget the coverboard!

I note that "coverboard" (such as DensDeck) is not mentioned in this post. Putting coverboard between the foam and the EPDM (or TPO) membrane is recommended in the manufacturer's installation instructions, may be required by fire code, and is the only smart thing to do if there is any chance that the roof will be walked on (i.e. if there ever will be a roof deck or drains that need to be cleaned) because it will keep the foam from breaking down at the edges of the panels. It's just a bad idea to put a membrane that should last 40 years down on a substrate that will start failing decades earlier.

Consider also in some areas a Class A fire rating is required for such roofs, which ends up as a layer of glorified drywall just below the roofing membrane.

Log in or become a member to post a comment.

Sign up Log in