Feeding the stove

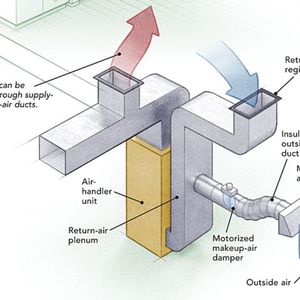

Wood stoves need air as well as wood. The question is, what is the best way to provide a source of outside combustion air in a very tight house?Image Credit: Justin Fink/Fine Homebuilding magazine

Wood stoves used to be pretty uncomplicated devices. Even though they weren’t airtight and they weren’t especially efficient, these cast-iron stoves warmed plenty of New England farmhouses in the dead of winter.

Our forebears never considered the source of makeup air to replace all the heated combustion gases that were going up the flue. They didn’t need to, because back then, houses were leaky. As the stove burned its load of oak or maple, makeup air had no trouble finding its way into the house.

In the era of airtight construction, however, a wood stove is a different animal altogether. For one thing, stoves are more efficient. For another, the current emphasis on air sealing has reduced the number of cracks and leaks that were traditional sources of makeup air.

Writing in a Q&A post at GreenBuildingAdvisor, David Meiland delves into the problem by describing two common methods of solving the problem.

“I’ve been wood stove shopping lately and noticed that ‘outside air’ for wood stoves is done in a couple of different ways,” Meiland writes. “The European stoves in general do not seem to have a direct connection for the outside air duct — it’s what the salespeople are calling ‘proximity’ air, meaning a 3-inch duct from outside terminates very close to the stove, but does not connect.

“The American stoves are much more likely to have a direct connection. To me, a direct connection makes perfect sense, whereas the ‘proximity’ air looks like an air leak.”

Anyone care to venture an opinion?

Adding a trap to control air intake

John Klingel is among those who wonders whether a trap could be installed in the incoming air duct…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

31 Comments

Stoichiometry

You can calculate the draw from the stoichiometric ratio. Dry wood is 6.1:1 (http://wiki.gekgasifier.com/w/page/6123822/Stoichiometric%20Combustion%20Ratios). Dry air at 70F is 0.075 lbs/cf, so one pound of wood burned over an hour will take in 81.3 cf of air, or 1.36 cfm.

Humidity adds to that of course, and the stove will likely admit a higher ratio of air.

Very Interesting

I received this from a friend (quoted in this article) a short time ago.

http://woodheat.org/outdoor-combustion-air-in-the-canadian-national-building-code.html

This is a very interesting conversation. So, There is NO data relative to combustion air in super air tight construction? I am talking Passive House and beyond...... .2-.6ACH/50. Now, I have to thank Kendall here..I get that if you only need 1.36 ish CFM to combust (completely), one pound of wood that you may not need make up air if the ambient mechanically ventilated airspace can with a supply rate of 80CFM can support burning...............10 lbs,20 lbs of wood at a time?

But what I dont understand is how when you close the door of the wood stove and that said door is truly airtight, where does the combustion air come from? .............IT CANT COME FROM THE HOUSE.

My gut tells me as well, that I want a well designed thoughtfully dampened make up inlet. I also want it connected to the stove. At the very least in new construction, I would want it available for the possible future use; so when that "oh shit" moment happens; when the fire goes out while someone decides they want to dry their clothes in the clothes dryer sucking 110cfm. i can then send someone over to connect it.

Thoughts?

This is a very interesting question.

Response to Christian Corson

Christian,

I think that even in a Passivhaus, when you close the airtight door on your woodstove, the fire gets its combustion air through the (dampered) air inlet that every stove has. This air inlet is usually part of the door itself. And yes, there should be enough air indoors to supply the fire with oxygen -- just as there should be enough air indoors to supply you with oxygen.

Moreover, when a powerful exhaust fan is turned on, reversing the flow of combustion gases up the chimney flue -- something that can easily happen with a range hood fan -- the fire won't go out. Rather, the combustion gases will be sucked down the chimney, and the increased draft will probably cause the fire to burn hotter, not go out. You'll probably see a puff of flame coming out the door of your wood stove.

CO2

I insulated my attic over the weekend. Also, I added a new boiler in the basement with a power vent last summer. Sunday, our first fire of the year in my Jotul 500, was a struggle all day. I got continuous smoke rolls in the house even with the vent open all the way and opening the door slowly. I finally got it going good by opening a window. I closed the window that night to go to sleep. The next morning my wife put clothes in the dryer and jumped in the shower with the bathroom vent on. Then the heating system kicked on. A minute after that all the CO2 detectors went off. We evacuated and opened all the doors to air out. I determined the smoldering fire and the negative pressure in the house sucked the gas down the flue into the house. I definitely need makeup air. I would love to see a plan or get instructions for the wood stove and my boiler. Any suggestions?

Outside Air Kit

James, the Jotul 500 has an outside air kit, which direct-connects to the stove.

http://www.jotul.com/en-US/wwwjotulus/Main-menu/Products/Wood/Wood-stoves/Jotul-F-500-Oslo/

Airtightness

As I understand it, an EPA stove can't be completely closed off. The various joints and seals in the stove are airtight, but the air supply has to be sufficient to keep the stove burning cleanly. Since the stove doesn't know if it's burning or not, there's no "off" setting.

I'm not sure if that's an explicit regulation, or a side-effect of the clean burning requirement, but it definitely interferes with the ability to shut down the stove, or close the air leak when it's not operating.

More on outside air kits

There is an interesting document containing information on outside air kits at the Hearth.com website:

http://www.hearth.com/econtent/index.php/wiki/Outside_Air_Kit_-_Why

"The Outside Air Kit (OAK) enables a stove to pull air from outside of the house rather than from the room the stove is sitting in. Unless you have a draft problem (difficult starts and backpuffing), an OAK probably will be of no value to you. Some argue that OAKs increase overall heating efficiency because the stove is no longer pulling cold outside air indirectly though the entire house but instead is pulling directly from the outside. However others would argue that home ventilation is actually very important, especially in modern tight houses, and that the effects of an applicance slowly replacing indoor air is actually quite beneficial."

More information on Jotul's outside air kits can be found here:

http://www.jotul.com/FileArchive/Technical%20Documentation/Wood%20Stoves/J%C3%B8tul%20F%20500%20Oslo/Manual_F_500_USA_P15_310111.pdf

Martin

Thank you for your response. First I realize that all wood stove have dampers. Those dampers allow air into the stove in a regulated fashion to allow for effective combustion. Ok, granted. If you need an additional 5-25 cfm for combustion which to me in reality seems low( I think these numbers are based on truly seasoned hardwood 2+years seasoned, ) Segue, to occupancy habits for a sec. Most people do not burn seasoned hardwood. they are sold "seasoned" wood that is one season old...three months. This greatly affects the amount combustion air necessary to make the stove operate, thus increasing the amount of make up air necessary.

Second. Passive House. Having designed and built a few,what I consider to be pretty airtight homes, I have noticed a couple of things. Besides the obvious and primary benefit of air tight construction; increasing the durability of the structure(i am a wood guy, we build with wood)by mitigating air infiltration and thus controlling moisture infiltration as well. There is the comfort factor. Now i am talking homes < .8ACH/50. There are NO drafts. The natural comfort of the house is increased considerably by adding high quality triple glazed windows thus eliminating even naturally occurring convective currents. Fine. Now we need to ventilate, so we do that in a balanced way while adhering to the ASHRAE 62.2 standard. Now that being said, we have established a ventilation rate of say 84 CFM for a two bedroom two bedroom home of 1600sf. 24 CFM from each bathroom 35CFM from the Kitchen and then match the supply, voila. Now 25CFM which to me is a LOW number for combustion is one third of the entire ventilation rate. That air is designed to be breathed by the occupants. Occupants trump wood stove. Another note.

"even the best rated airtight firebox will still have minimal leakage and secondly, the ventilation system could potentially significantly depressurize the house, if for example one of the two fans breaks. If the failure goes unnoticed until the house has been depressurized smoke can be drawn into the living space from the firebox or stove, no matter how airtight it is."

Lastly ......."Moreover, when a powerful exhaust fan is turned on, reversing the flow of combustion gases up the chimney flue -- something that can easily happen with a range hood fan -- the fire won't go out. Rather, the combustion gases will be sucked down the chimney, and the increased draft will probably cause the fire to burn hotter, not go out. You'll probably see a puff of flame coming out the door of your wood stove."

This is a backdraft, and it is very dangerous. I dont want gases coming out of the chimney into the house.

I am in a hurry, and trying to quickly have a thoughtful discussion about this, so forgive me if I left out something obvious.

cheers

Response to Christian Corson

Christian,

You wrote, "This is a backdraft, and it is very dangerous." No kidding! That's why I advise people that powerful range hood fans are incompatible with wood-burning fireplaces, wood stoves, or atmospherically vented water heaters or furnaces.

More information here: Makeup Air for Range Hoods.

Saskatoon Loop

Around here (Toronto), the combustion air inlet 'P trap' was known as a "Saskatoon loop" and though the idea was promising, it didn't take alot of pressure to overcome the dense air "trapped" at the bottom of the loop.. maybe if the P was really deep.. Not used much anymore.

Regarding Passive houses, do wood stoves belong in PH?

Outside air and HRVs

I've been round and round with this issue on the Jotul stove we're planning to install soon in a little 1550 sf house that is built tight, but vented with an HRV. Our first instinct, going on advice from the HVAC folks, was to install makeup air.

We encountered a little trouble as to exactly how much air the little stove would need, and in calling a Jotul representative directly, were told we'd actually need a damper on the metal chimney flue to keep the stove from overheating! His thinking was that the straight shot of 25' metal chimney that is all interior(first floor through second floor and cathedral ceiling to the peak) would become a strong enough updraft to suck more air through the stove than was intended.

My fear is that when she turns on her kitchen hood, she could backdraft the stove, but it sounds like the HRV is essentially setup to allow more air through already, so why poke another hole in a house we're trying to keep tight!

Based on numerous discussion with everyone we could talk to that had an official or informed opinion is that the HRV will allow enough makeup outside air. No one can give a definitive answer as to how this exact setup will work in this particular house, so before cutting another hole in the side of the house, we'll install the stove and monitor it's behavior closely, adding a duct for makeup air only if necessary.

Martin- Thanks.That was

Martin- Thanks.That was funny. I actually laughed out loud as I was waiting for a sandwich yesterday. I understand what you are saying. My trepidation is relative to PH specifically. Can a dryer vent cause a backdraft in truly airtight construction? I dont know a bout that, probably not. Could it prevent the stove from completely combusting..........Maybe? I think with the combination of unseasoned wood ,low volume air supply, occupancy habits, and a dryer thrown in there, raises some valid questions.

Greg

In the first PH that we built I really pushed for a condensing dryer and NO wood stove. We have double sized our heat load with a small ASHP in a 7345 HDD environment. So...that being said, a wood stove is totally unnecessary. However, I am one of those guys who is ALWAYS looking for a different solution. Even when the solutions we have are adequate. To me that is how we evolve.

There are a few things that appeal greatly to me in regards to wood stoves in PH.

1st -By returning to biomass we can further reduce our primary energy demands. What if one day in my lifetime I can design and build a house that has a SPED(specific primary energy demand)of 0. That is probably not possible, but it is a cool idea and worth working towards.

2- If the power goes out there is not only heat but the capacity for boiling water and baking bread.

3- increases the potential for off grid living.

4- Client driven requests. I dont want to put a fireplace in any home. So.... when I have a prospective client say " I am a leo, and I have to have fire" I think Rais Rondo w/ the turntable. hence these other concerns

final note- as far as I know PHIUS strongly urges to stay away from wood. If wood is used they are adamant about make-up air. I am on the fence myself, I can definitely see both sides. And I feel there are VERY valid points but NO actual "real life"data. Having seen how "air tight " construction performs, I tend to think make up air MIGHT be needed in certain situation.

We built a house 7-8 years ago with a masonry heater (with no MU air) and the clients still tell me we love the house everything is great (we never had a single call back) but we cant get a fire lit unless we open the dining room window. It still bothers me. Even though it is in a predominately cooling climate and that heater gets used probably twice a year. Christmas and New years.

More on Passivhaus and wood stoves

Christian,

1. As you know, most Passivhaus advocates advise against the use of a wood stove in a Passivhaus building. For those who live in rural, forested areas of the North, that raises many questions -- including, "Why bother with Passivhaus? A small wood stove meets my needs, and I know it works. So I don't need to aim for 0.6 ach50."

2. Every HRV and ERV manufacturer is in agreement on one point: they all explain that an HRV is not intended to provide combustion makeup air because it is a balanced ventilation appliance. Air in = air out.

3. Nevertheless, Passivhaus advocates (and others) often overstress this point. I call it the "smart air fallacy": namely, the false belief that air always follows the "smart arrows" you see in the ventilation diagrams. In fact, even in a house with an air leakage rate of 0.6 ach50, makeup air usually finds its way in to the house when a bathroom exhaust fan is turned on or when wood smoke goes up the chimney. This air comes from all the usual cracks around windows, doors, and framing members, as well as through the ventilation intake ports. If the house needs more makeup air, it finds its way in.

4. Nevertheless, if an exhaust fan is big enough -- the classic example being a huge range hood fan -- atmospherically vented appliances will backdraft. That's why we should be very careful to keep exhaust fans as small as possible, and to whittle down (or even eliminate) the number of atmospherically vented appliances in our homes.

Modulating air loads

With all of these variables, a tight home construction needs comprehensive air management. An HRV at one setting will suffice for a woodstove alone, however, with other de-pressurizing appliances operating, more air is needed. Hence, an HRV that can modulate with the air-load requirements of the home. Do these exist? Or, alternatively, an OAK for the stove.

Makeup air via HRV

At least with some HRVs, if it is on when some other exhausting device is operated, the in/out air flow via the HRV will become unbalanced and tends to allow more air in than is sent out. I know this is the case with the Lifebreath 195ECM that I have. When the blower door test was done, we had to turn off the HRV, of course. With it on, I could feel the difference in the air temperature coming in while the blower door fan was running. With the HRV off, an internal damper closes the outside air flow so as to prevent unwanted air intrusion.

A woodstove is a mildly exhausting device, in that there is a strong stack effect due to the large difference in flue gas density vs that of the combustion air entering. Still, I would expect that a strong exhausting device (the proverbial huge range hood fan) could backdraft a woodstove without a directly connected OAK, despite any tendency of an HRV to makeup air by running out of balance.

Have had outside combustion air source for several years....

I have a Jotul 500 and used it for a couple years without an outside combustion air source, and it worked well. Then I installed a metal duct from the outside to supply combustion air to the stove using the connection kit from Jotul. It works even better now than before. I have a pretty tall interior chimney (30') with a strong draft and have never noticed any backdraft issues mentioned above with hot embers being puffed back into the intake duct.

I only have anecdotal evidence but I am convinced that when we use a humidifier now, it seems to have to run less often because of the combustion air supply for the stove being in place now.

Another added benefit in my mind is that when the fire goes out there is not a supply of warm house air slowly drifting up the chimney being pulled by the natural draft of the chimney. All it can do now is suck some cold air from the outdoor air supply! I am sold on using a dedicated and connected combustion air supply for a woodstove.

Clarifying

My understanding of the proximate air duct is that outdoor air, usually cold, when added to the hopefully hot firebox, reduces the fire temperature and so the efficiency of the burn, increasing pollutants. After reading everything out there, I will soon be adding a proximate air port to the exterior wall behind my woodstove. Yes, in a <1 house.

Flow rate based on stoichiometric ratio?

It appears as if the low flow rates tossed around are based on the stoichiometric combustion ratio mentioned at the beginning of the thread. Won't a fire draw a much larger volume of air than the simple ratio? In addition to the chemical reactions between the fuel and the air, there is expansion due to heat which pushes gases up the exhaust and draws in a correspondingly larger volume of air.

In a sealed fireplace with combustion air supply, this isn't an issue. However, my particular problem is with a wood-fired oven. I have a tight house and am hoping to minimize the volume of interior air exhausted due to burning in the wood oven. To that end, I have constructed a makeup air apparatus consisting of a 4" duct vented to the outside and terminating in close proximity to the mouth of the wood burning oven. Spent some time trying to figure the fire draw, but in the end just went with a 5" duct on a guess.

outside air efficiency gain?

Using outside combustion air makes all the sense in the world to me. why draw cold air into a house and send conditioned air up the chimney. I've installed 3" duct outside air on all inspected jobs per code. On un inspected job our local stove guy says don't bother, I suspect he does not want to crawl underfloor.

I wish I could tell my clients that they will get X% more heat per wood burned. Does anyone know if outside combustion air, fully piped, not proximity adds 5% or 10% or 15% greater efficiency? I'd love a ballpark # for a typical wood stove.

Response to Tom Tharp

Tom,

A technically accurate answer to your question is difficult -- perhaps close to impossible. Monitoring data might be useful, but its very hard to set up an experiment in which two wood stoves are fed fuel in an identical manner. It would be an expensive study.

Suffice it to say that I doubt whether the savings would be significant. It's true that providing combustion air directly to a wood stove will reduce the amount of infiltration entering the house through random cracks. But ducted combustion air is colder than combustion air that enters the stove from your living room, and that means that the ducted combustion air steals some of the heat from the stove compared to the warmer unducted combustion air.

Still confused

We built a house that is probably around 0.6-1.0 ACH50 (not tested yet).

I'm undecided on the outside air kit (OAK).

The home has an HRV (of course).

We have a gas range with hood.

Each bathroom has an exhaust fan, but each bathroom also has an HRV ducted exhaust (so the independent exhaust may not really be needed...).

The dryer has no vent (Whirlpool hybridcare).

The chimney is long, tall and straight. Probably 30'+ from stove to top.

Currently the wood stove has no outside air kit. But we're not moved in yet and it's never been used yet.

Our primary heat will be the ASHP.

Should we install an outside air kit?

Response to Patrick Campbell

Patrick,

Once a house gets as tight as you are talking about, wood stoves get a little iffy.

For more information on this issue, I suggest you read All About Wood Stoves. Focus on the section that begins, "Can you put a wood stove in a Passivhaus?"

Wood Stove Makeup Air

Some poorly designed houses with powerful vent fans or more than two bathroom fans (80 cfm X 3)that may be on in the morning at the same time as the wood stove is needed to warm up the house at the same time as someone is burning the bacon making breakfast (160 cfm) will benefit greatly from a wood stove outside air intake. Thoughtful design (a baffle on the outside of the intake orifice if needed) will prevent the Venturi effect (like blowing across the top of a bottle) that could potentially draw the air out of the intake opening. A house like mine with trees that have grown tall around the house and no makeup air recovery system could not support consistent wood stove combustion even with a chimney extension. With the outside air intake it works fine.

For most installations though it is redundant and carries a tiny risk if sloppily installed.

Follow up from builders?

This article was written 5 years ago. I am hoping that in that time, a number of you may have built "pretty good houses" that approach PH standards and have some feedback on this issue. We are planning a pretty good house and would love to have a small wood stove in conjunction with mini-splits. Thanks in advance for any input from builders and the writing community!

Response to Robert Young

Robert,

Two years after this article was published, I wrote an article that included an extensive discussion of this issue. In case you missed it, here is the link: All About Wood Stoves.

And just last week, Elden Lindamood posted a relevant article on the topic. Here is the link: Relative Humidity and Makeup Air at a Tight Minnesota House.

I wanted to comment on this post with something I have not tried yet, but I'm assuming would work quite well for using a wood burning appliance "without" the hood fan on. There is an ERV by Panasonic called the Intelli-Ballance 100 FV-10VEC1, and it has not only auto balancing, which I'd assume on it's own, would probably auto-adjust the incoming air stream to add somewhat conditioned (and at least filtered) makeup air automatically when it detected the negative pressure created by the wood-stove's ever increasing draft during start up... it also has manually and independently adjustable CFM (from 50 to 100) on both the incoming air intake as well as the outgoing air outlet. Thus, you can create positively or negatively pressurize your home as you see fit with the turn of a knob. One great use I can think of for this is if you normally have a difficult time getting your wood-stove started, you can give a short twist-click of the incoming air knob on the Intelli-Ballance ERV, and it will automatically create slight positive pressure in your home thus most likely making it much easier to get it started (think gently fanning a campfire at start up with a piece of cardboard for those who have done so). Note that when adjusting the Intelli-ballance (IB) ERV, it states that it will "remember" the new pressure setting, and use it's (IB) feature to maintain it at that pressure. So, if you have 15 CFM of additional airflow into the house, and your house is closed up, other than the wood-stove flue, most of this 15 CFM would be running up it's flue. Now, as the wood-stove ramps up, the (IB) will auto adjust to add even more incoming air into the house via the ERV's venting sytem. Anyway, this seems like it would solve a lot of issues people are having with such things. On the negative side, currently, this ERV only comes in a 100 CFM version, so, from my calcs. under the new ventilation requirements, this stove would serve up to approx. 2000 square feet, but that's only if you had it on full power, which means you could only adjust one of the fan speeds down to create to create - or + pressure, which means you'd have to cut your ventilation rates in down in order to mess with the manual pressure balancing feature the unit offers. Plus, even at 100 CFM, this meets only the new minimum standard for a house of around 2,000 feet, so if you have a bad air quality issue you want to account for be increasing the ventilation rate, your out of luck. IMO, this unit is ideal for a house of up to around 1,200 square feet with average height ceilings. The manual says up to 3000 square feet and 7 BRs... not sure where they are getting that from, but I think it's way off. There is the option of adding two units for handily ventilating up to around 2,400 feet or so, maybe on different floors, but if these two areas are connected, then one of the units will always auto-counterbalance any manual adjusting you try to do to the other unit with it's integrated (IB) feature, which a rep from the company told me could not be turned off. The other disadvantage is that this unit can be controlled to turn on or off by a remote switch, but that's about it. You cannot control the fan speeds or the time on vs time off of the unit from afar, so you'd have to physically go to the unit to adjust any of those controls. It also does not integrate with other functions as far as I'm aware. So all in all, if you have a smaller, tight house, with a wood stove, and are looking for a simple, quiet, quality unit to ventilate your house for you, this could be a great option.

Jeff_LDC and Benneaf3,

Creating positive pressure with an adjustable ERV might work as a source of make up air when nothing else is operating, but the problem with back-drafting occurs when appliances like the vent-hood, bathroom exhausts and dryers are going. ERVs don't have the capacity to overcome the high CFM being exhausted by those.

Couldn't you just install a Panasonic erv to bring some fresh air into the house? https://na.panasonic.com/us/home-and-building-solutions/ventilation-indoor-air-quality/energy-recovery-ventilators/whispercomforttm-erv-balanced-air-solution

we installed a wood stove in our basement during our remodel. we installed it before we spray foamed. before insulating it lit up quickly but since then, as more and more air gaps are filled, it’s gotten slower to lite. cracking the window for 5-10 minutes helps get the stove humming.

so, i’m looking at options for an outside air kit. one possibility is using the air coming into the sump pit from the bottom of the basement stairwell. we have a 3’ trench drain with 4” pipe leading to a 3’x4’ fiberglass sump pit inside the house. there are already a few holes in the lid and when the stove is lit you can really feel it the air moving through these holes.

so i’m thinking about cutting a new 3” hole in the lid and inserting the outside air kit from the sump to the woodstove. do you all think this is a reasonable design?

homeowner007,

Before getting into a discussion on whether it's a good idea or not, the two places to start are your building code and the wood stove manufacturer's requirements. Both would preclude using the trench drain here in BC.

A common approach to mitigating radon is to seal the sump pump well and stick a tube into it with a fan that vents it outside. That sounds like what you are doing but instead you are venting it passively into the fireplace. The risk is that if there is any leak at any point or a backdraft into your house at any point you could be pulling radon into your house. Both when the fireplace is operating or when it is not.

Log in or become a member to post a comment.

Sign up Log in