Planning a rainscreen

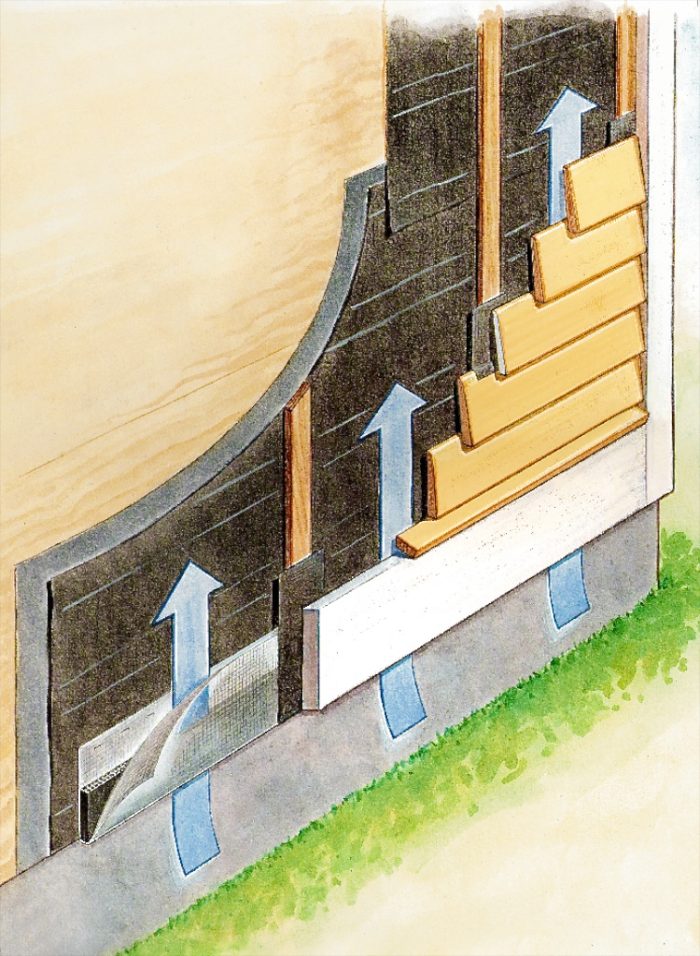

A rainscreen, designed to encourage air circulation behind the siding, typically includes furring strips applied vertically. A builder wonders whether he'd get the same benefits by applying furring horizontally.Image Credit: FHB

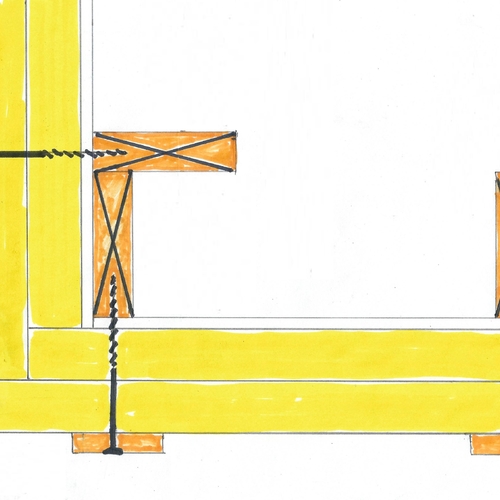

Aaron Vander Meulen is building a house whose exterior walls will consist of 2×4 framing with cellulose insulation, bracing, 2 in. of extruded polystyrene (XPS) foam, furring strips and, finally, Extira siding, an exterior grade wood composite.

Meulen is leaning toward horizontal rather than vertical furring strips because they’ll make it easier to install the 2-ft. by 4 ft. panels.

“Running the furring strips horizontally allows the panels to be fastened in a location the makes sense for the panels, as well as allowing some customization of panel size,” he writes in a Q&A post at GreenBuildingAdvisor. “What am I missing/overlooking?”

Horizontal furring is a problem

Installing the furring horizontally might make it easier to put up the siding, but it will to cut down on the flow of air behind the siding and will block the drainage of any water that gets past the siding.

Torsten Hansen suggests offsetting the furring away from the foam to allow back-venting of the panels. But William Geary suggests even this won’t be enough.

“The horizontal furring strips are the problem if you don’t provide for (1) sufficient drainage for the rainscreen (this will be blocked by the horizontal strips), and (2) sufficient vertical airflow behind the siding (this also will be blocked by the horizontal furring strips,” Geary writes. “I doubt you can cut enough kerfs to provide for adequate drainage AND airflow.”

Instead, Geary suggests one of three options:

“Whatever you do, make sure…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

11 Comments

Life on the bleeding edge

Boy. Rainscreen or no rainscreen, looking back at the picture on the OP those long horizontal flush joints look awfully vulnerable to me, especially with a milled top edge to the siding material. If I were the contractor on a project where the client was insisting on this look I'd plug a serious disclaimer into my warranty document and recommend regular pre-emptive maintenance inspections. And to give the assembly a fighting chance I'd also recommend protecting the walls with a darn good roof overhang with no more than a single story height exposure, and making sure the bottom of the siding was well above the splash zone, certainly more than the code-minimum 8".

I see no mention of a location of this project - maybe I missed it - that could make a difference. If the location is in a dry climate with infrequent moisture events it'd probably be OK. In an exposed location subject to wind-driven rain I'd stay away from this altogether. Signage is signage. It's not expected to last forever. I'd sure want more than a 5-year warranty on an integral part of the weather enclosure of any home I was professionally responsible for.

Caulked seams

I also note this comment in the manufacturer's documentation:

"When designing products made with Extira, always allow for the natural expansion or contraction of Extira due to changes in its moisture content and assess interaction with other components in the final product. Like other wood composite material, the moisture content of Extira will change based on the ambient relative humidity and environmental conditions to which it is exposed."

In a trim piece that movement will be only a small fraction of a millimeter, while in a 2' vertical panel width movement could easily be enough to destabilize a caulked seam in a fairly short period of time - again, depending on local climate conditions. There's a reason traditional siding materials almost invariable rely on lapped joints which are free to move.

Siding

I would consider a rabbeted bevel cedar siding, it is still affordable and if primed on all sides before installation will hold paint for a long time.

alternative

alternative option...

vertical battens w/ a layer of horizontal counter battens. for rainscreen w/ vertical siding, is our preferred approach. detail is used throughout much of EU for walls (and especially roofs)

http://baublog.pichuraconsult.de/__oneclick_uploads/2009/06/sdc11469a.jpg

Mike, the failing point of

Mike, the failing point of the system in your picture is batten failure due to drying out the wood till it is brittle unstable junk.

But for sure until the battens or roofing fail, that roof will be dry!

To add longevity the battens should be beefier.

Home slicker and flashing details

We use "home slicker"/"cedar breather"/"whatever the same mesh material is called from some other supplier", precisely because it's thin enough that conventional flashing & window details work fine.

I'm looking forward to seeing this new Obdyke drainage wrap too, but the 1/4" deformed mesh materials work very well and are easy to detail.

I also agree with the specific concern over the siding materials in this thread, and with Martin's general point that any space behind siding will allow it to perform a lot better than none, even if the space isn't detailed for a vertical flow of air. Just changing from a sandwich of siding-wrap-sheathing with no gap, to an assembly with some gap, seems to make a huge difference.

Horizontal vs vertical furring strips

Just a question: - why not apply the furrings strips diagonally? - this will allow drainage and airflow required.

Question for Greg

Greg

Will your furring system work over a thick layer of foam insulation? Do your strips hold nails?

Question for Greg re: Furring Master over Thick foam

Hello Garth, yes the Furring-Master(TM) can be installed over thicker foams. We use the 20 gauge Furring master that we just came out with for this application. Yes you can apply the cladding to the Furring Strip on the 20 gauge. On our 22 gauge you must penetrate into the framing so the 22 gauge would not be the correct strip you need for this application. The 20 gauge is. You will need to use self drilling screws. What type of cladding are you applying over the rain screen? Please call me direct with any questions at 402-686-4257

Rain screen Furring Strips placed horizontally

Hello Martin, Greg Albracht here, we have a new Rainscreen strip that works fantastic for this exact application. It WILL allow air movement both vertically and horizontally. Its our Siding Master(TM) Product that you reviewed years ago in Energy Update Magazine.

This is far superior to wood furring strips, plastic batten or those expensive mesh rain screen products that can cause problems with wavy siding if nailed too tight. Our system includes top and bottom vents (Screened). James Hardie(R) Siding has referred many large companies to us who have used the Furring Master and who have re-ordered.

Patent Pending Furring Master (TM) is by far the BEST Choice for any rain screen application, that is not our opinion that is our customers.

New Furring Master (Two) Aluminum PVC Coated Furring Strips (Hat Channel)

https://sites.google.com/site/gorillagutterguard/our-products/furring-master-rain-screen-system

Furring Master Website:

http://sidingmaster.com/Furringmasterfibercement.htm

Horizontal furring strips are no problem

if you want vertical siding for your exterior layer, just install two layers of furring strips; the first is vertical, installed directly over the interior studs. Then apply a second layer horizontally, which will receive your exterior boards. The best part of this system is that you don't need to rely on expensive metal or plastic furring strips, and you don't need to rely on pressure treated wood. The double layer of furring strips creates a very airy cavity behind the exterior wall, allowing air to move vertically and horizontally at will.

But i am also curious... has anyone heard of installing the furring strips diagonally? Pros/cons of doing this?

Log in or become a member to post a comment.

Sign up Log in