Mhenson has broken ground on a new house in the Colorado mountains, and he’s having second thoughts about his plans to use double-stud walls, a construction method in which two framed stud walls are separated by a gap with the entire assembly filled with insulation.

“I have done a lot of reading and had settled on double-stud walls until I read a couple of articles that said they may be risky,” Mhenson writes in this recent Q&A post. He worries that moisture may accumulate in the wall cavities, so he’s switching gears and now wants to use a wall with a continuous layer of foam insulation on the exterior.

The house will be at an elevation of 10,500 ft., and while it’s a high-altitude desert it’s still wetter than most of the state.

“My framing contractor is not a fan of this over the double-stud wall,” he adds. “Time is of the essence. Can someone set me straight on what is now considered to be the best method? Especially if neither of these is best!”

So what’s it going to be? A double-stud wall, or exterior foam over a conventionally framed wall? That’s where we start this Q&A Spotlight.

Risks are ‘mostly theoretical’

Malcolm Taylor believes that although there are theoretical risks of moisture accumulation in double-stud walls, “it doesn’t seem to be occurring in practice.”

Taylor refers Mhenson to an article Ben Bogie wrote for GBA, in which he refers to the moisture potential of double-stud walls as the “yeti of building science”—a beast of myth not reality.

That said, Taylor recommends that Mhenson make sure the assembly is well air-sealed, and that it includes a rainscreen to promote drying to the exterior.

Taylor adds: “Both double-stud walls…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

9 Comments

When we did our double stud wall, we made sure that the Advantek sheathing seams were taped, as were the housewrap seams. And we used a membrane on the outside of the inner stud wall as an air/ moisture barrier. Doing the membrane kept penetrations for plumbing and wiring inside the air barrier.

A big advantage to double stud walls is that they are simple to build.

I personally just used google to search “Double stud dense pack cellulose wall failures”, and “exterior insulation wall failures”.

I tried different words in the search box, but in the end it was really easy to find pictures / reports of exterior wall failures with foam, and challenging to find reports of dense pack cellulose double stud wall failures.

Admittedly, this could be due to far more houses being built with exterior foam, as opposed to double stud walls. But I don’t have any data to back this up.

I was also unable to find images or reports of wall failures when the house used exterior wood fiberboard, or rockwool.

If anyone has any info that is different than what I found, I’d be interested.

Ben

I think I mislead Bill a bit. A big part of why you don't hear about failures (or successes) of double-stud walls in the PNW, is that no one builds them. The climate is too temperate for most people to consider them as a wall assembly here.

As an example of the mildness of the climate in the PNW: The Pretty Good House book recommends a whole wall R-value of around R-25 for a PGH in CZ4 (which is much of the PNW).

You can get that with a 2x6 wall with R-21+6c.i., or a 2x8 Wall with R-30. Why go to the extra hassle of a double stud wall, when there are simpler and thinner solutions?

I imagine the majority of the double stud walls in the PNW are on houses targeting passive house certification.

This article is great to have summarized into one spot, especially including the links. I've said for years when the time comes to build my own home that I'd go with a double stud... but this article just gives me more food for thought.

If one is considering using exterior CI, GBA has a great post on how much is necessary.

That crew really looks like they know what they're doing. I'd trust whatever they say.

Well, that was a good read and a little embarrassing, but when you are the least experienced guy in the forum, humility is a good place to work from. What I decided to do in the end is:

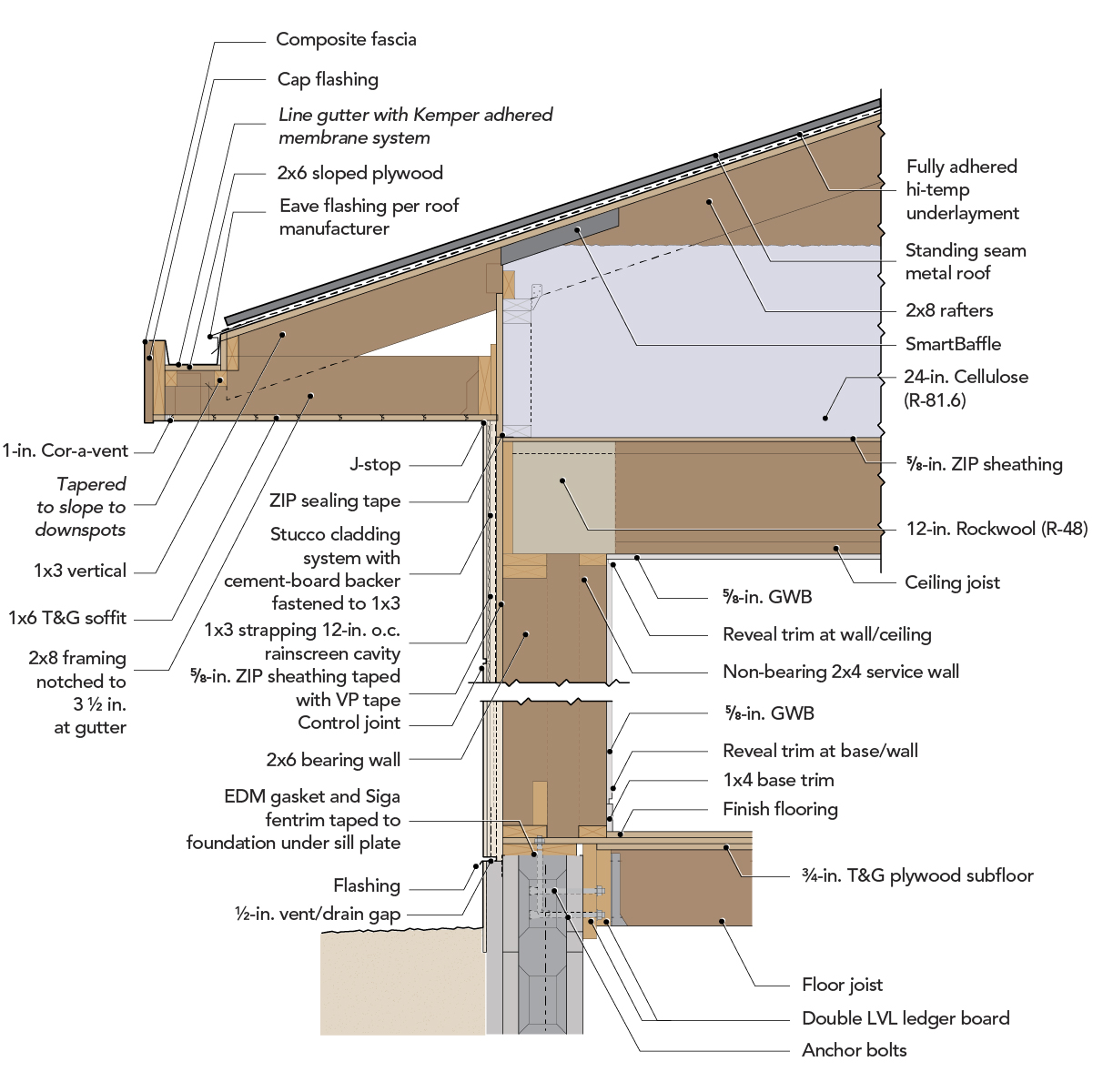

A well sealed and taped rain-screened offset double stud wall with polyurethane sealant between all plates, 24"-on-center, unfaced R21 HD fiberglass batts between the 2x6" wall, followed by a membrane attached to the 2x6" wall. Then a layer of faced R21 HD Fiberglass batts in the 2x4" wall covered by drywall.

On some level I feel like I am in the car with a crazy driver because:

While I can order in cellulose, there isn't a competent installer anywhere within 100 miles of me, I spent days calling and trying.

Blown-in fiberglass is cheaper and easier but I have seen it settle over time, I have torn down a lot of old walls and batts seem to hold their form much better and HD fiberglass should do better still. Yes, the average blower door is worse on batt installations, but I am betting on batts beating a 1/2" sag over 10 years, and am detailing the living #&%@ out of the exterior wall.

I am working with the only available subs in the area for almost every part of the construction. Not the best or worst, the ones I can hire in a market where every sub is scheduled out a year or more! Most have seemingly never seen an energy efficient house.

They range between fascinated and irritated by my insistence on the details of every part of the construction. I am trying to go over all the details and why they are important BEFORE they actually start working and may lose some of them because "there is easier work out there." They liked California corners, but didn't like the effort involved in build them, they wanted to charge way more for detailing the bottom 1/3rd of the walls with sealant on over driven nails etc. They like taping seams, "great idea", they have seen that before, but think it is ridiculous to buy tape that works best with primer and must be rolled when you can get cheap "Force Field" tape that doesn't require any rolling and "works really good". They also think I am wasting money on Tyvek Commercial D wrap, but it is easier to install so they like it. Please let me know of any mistakes you see!!

In the end I and my son will do the sealing on the over driven nails etc. as it is easy and avoids a 20% increase in the framing labor cost. Thank God, I found a plumber that knows what he is doing and can get the in-slab PEX installed correctly.

Just doing my honest best to build a "pretty good house", with a budget/loan that was made when labor and materials were at 2020/21 pricing, and skilled labor was much more available.

I am deeply appreciative of the help everyone has given via articles and the forum.

Warning there will be more dumb questions before this house is complete.

We are in a similar situation - planning to build a double stud home in interior BC where there is no local hi-density cellulose installer within a couple hours drive. Someone in town is planning to bring in the equipment for his own build & then lease out to others, but after reading articles like this I'm not certain we want to be one of the first projects.

It makes me lean towards mineral wool. Worse on the embodied carbon calculation. But this is our "forever" retirement home so want it to pass the test of time.

Thoughts appreciated. Thx.

The risks of double stud walls with cellulose lie more in the realm of modeling and theory compared to the risks of exterior rigid foam where the real chance of poor workmanship will lead to a significantly higher chance for failure given the attention to detail needed to install window/outlets/hvac penetrations/outdoor faucets through sheathing and exterior foam.

Log in or become a member to post a comment.

Sign up Log in