Although I wrote a 2012 article for Fine Homebuilding on ways to insulate the cramped attic behind a kneewall, I’ve never written such an article for GBA. So it’s clearly time for a comprehensive article on the topic.

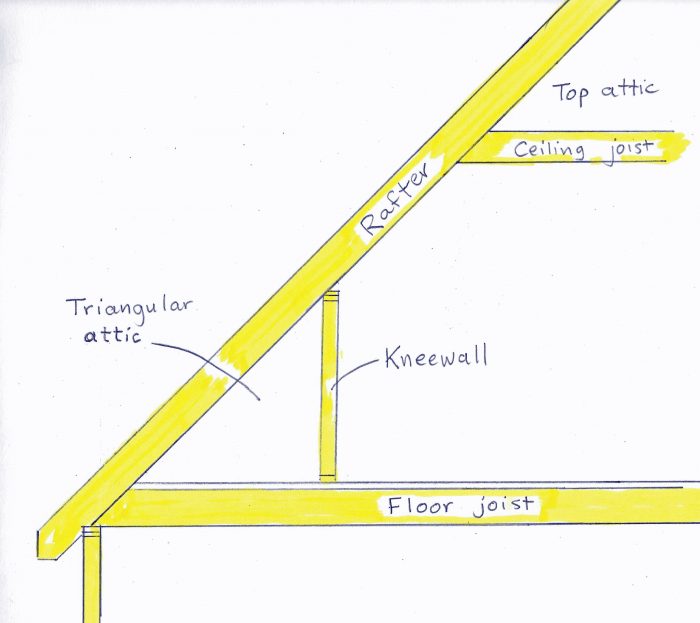

A kneewall is sometimes defined as “a short wall under a sloped ceiling.” A typical kneewall is between 3 and 5 feet high. In most cases, a room with a kneewall has a sloped ceiling that extends from the top of the kneewall to normal ceiling height—about 8 feet off the floor. At that point the sloped ceiling usually transitions to a horizontal ceiling.

This description applies to the top floor of many one-and-a-half-story homes (like Cape Cod homes) or to a typical bonus room above a garage. Kneewalls can also be found on the top floor of some three-story or four-story buildings.

The illustration below shows the various components I’m talking about. (Note that the word “kneewall” refers to the short wall—not to the cramped attic behind the kneewall.)

Insulation challenges

If you are insulating a house with kneewalls, you face an important decision: Should the triangular attics behind the kneewalls be included in the home’s conditioned space, or should they be excluded?

For a variety of reasons, the best approach is to include these triangular attics within the home’s conditioned space. Bringing the triangular attic into the home’s conditioned space makes the task of air sealing much simpler, and is the only acceptable method to use if the triangular attic includes ducts or plumbing pipes.

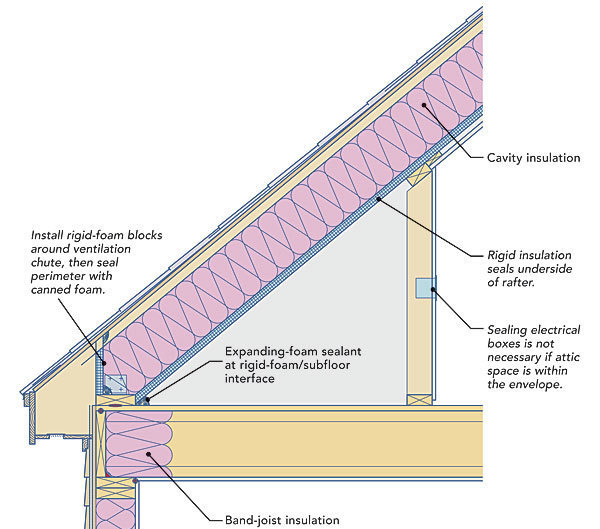

If you go this route, you’ll need to insulate along the sloped roof assembly, all the way from the area above the top plate of the exterior wall (at the floor of the attic) up to the “top attic” above the…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

24 Comments

What if the area below the devil's triangle is not a conditioned space? My new home will have a covered porch, and the devil's triangle is above it. Using your first diagram as an example, move the exterior wall under the joists so that it is directly below the knee wall, and the left side of the roof/joists is supported by columns. The underside of the covered porch has a ceiling, i.e., joists/rafters are not exposed.

I'm being told to spray foam between the rafters all the way down to the end of them, and to spray foam above the covered porch ceiling between the end of the rafters and the exterior wall under the knee wall, then spray foam the exterior wall. Do you agree with that approach? How much open cell foam should be used in the area above the covered porch ceilings?

There are actually two covered porches. The front porch is 50' wide and 8' deep. The back screened porch is 50' wide and 12' deep, so the total area is 1000 sqft. Both porches have 10' ceilings. The house architecture is "southern Louisiana".

Thanks,

Ira

Ira,

The basic principle of insulation is that the insulation boundary must be continuous around the building, with an air barrier adjacent to the insulation layer. In some cases, a builder can choose between two ways to proceed.

If you don't need your "devil's triangle" to be conditioned -- in other words, if there are no plumbing pipes, ducts, or vulnerable items in storage there -- it's OK to design your house so that the devil's triangle is outside of the home's thermal envelope. In most cases, this is tricky, though -- because it's hard to make the thermal boundary continuous and airtight.

In your case, it's your choice. If the roof assembly above the devil's triangle is insulated, you'll also need to insulate the floor of the devil's triangle (since you have a porch below). On the other hand, if you want to keep the devil's triangle unconditioned, you'll need to insulate the kneewall, and you'll need to make sure that the air barrier is uninterrupted -- especially between the floor joists directly under the kneewall.

Hey Ira,

Where is your new house going to be located? In Louisiana?

I'm to the point of considering converting a 1940's cape code into a "normal" two story with large overhangs. Mostly to get rid of all the issues with inability to properly insulate the areas mentioned in this article. The "back" half of roof is 4/12 sloped and has only 4" space between ceiling near end of rafter leaving no room for proper amount of insulation. It has all the typical problems shown here in GBA with moisture condensing on underside of roof sheathing and massive ice dams. The thought of being able to just dump 2' of cellulose across an entire vented attic floor sounds so nice compared to the nightmare of fixing all the intricacies of a cape cod style.

David,

You're right. A Cape Cod style house is a nightmare to detail right. In most cases, establishing a continuous air barrier is extremely difficult, and the sloped ceilings aren't deep enough for adequate insulation.

Compared to a Cape, an ordinary two-story house with an attic above the second story is a pleasure to insulate. If the house has raised-heel trusses, you just blow 16 inches or 24 inches of cellulose on the air-sealed ceiling, and you're done.

Dear Martin: Great article on a major problem -- particularly with remodels and upgrades for homes in New England built in the mid-1900s. Our home in Massachusetts has classic knee walls, and when we hired a company to install poly spray foam I wondered "How can we also solve the knee wall problem?" Cold winter air flows directly into the joist bays -- cooling the entire floor / ceiling. I did not want to tear out all of the interior knee walls, however, and pay for all of the plaster and paint repairs. More than half were also inaccessible.

We found a good solution: remove the soffit trim board on the exterior, which opened the end of all of the knee walls. Our foam installer simply filled half of the knee wall 'triangle' (including the end of the joist bay) insulating and air-sealing these pockets. We also replaced the soffit trim with cellular PVC -- which will never rot and never needs to be painted.

I hope this tip is helpful to other readers with similar homes. Thanks again for all of your excellent work!

Mark Hays

Mark,

Thanks for your comment. Indeed, it's often easier to access this tight area from the exterior of the house (by temporarily removing the soffit) than from the interior. There are a lot of variables, though, so this approach won't work on every house.

Hi Martin,

I’m very glad to have found your article. I am collecting bids to insulate the attic in my 1936 Georgian located in Northeast Ohio. It’s a large attic space (60’x30’). The knee wall is probably 5 feet high, and there is plenty of clearance in the top attic. I have found two insulation companies who will spray closed cell foam to the top attic and devil’s triangle. There are 6 inch rafters between the knee wall and the top attic that are the issue. One contractor said I would have to tear down the plaster walls to spray in foam properly. Another contractor said he would spray the rafters with dense packed cellulose (6 inches).

Is it okay to use two types of insulation on the same wall? Ripping down the plaster walls is cost prohibitive.

Thanks for your help!

Brett

Brett,

Q. "There are 6 inch rafters between the kneewall and the top attic that are the issue. One contractor said I would have to tear down the plaster walls to spray in foam properly. Another contractor said he would spray the rafters with dense-packed cellulose (6 inches)."

A. If you are talking about a sloped ceiling framed with 6-inch rafters, I'm not sure why a contractor would recommend "tearing down the plaster walls." Perhaps the contractor meant "remove the plaster ceiling" on the sloped portion? If that's what the contractor meant, the contractor is probably right. For spray foam, you need good access.

The second recommendation -- to "spray the rafters with dense packed cellulose (6 inches)" -- is also confusing. Dense-packed cellulose is blown through a hose -- it isn't sprayed. If you are insulating a sloped ceiling with cellulose, you first need to establish a ventilation space that has no insulation, between the top of the insulation and the underside of the roof sheathing, and that ventilation space must extend from soffit vents at the bottom to the top attic above. To install that type of ventilation space, you almost always need to remove the plaster or drywall on the sloped ceiling for good access.

For more information on another (somewhat tricky) approach, see "Sliding Insulation Between Rafters From Above."

Q. "Is it okay to use two types of insulation on the same wall?"

A. Yes, as long as the insulation materials are placed in such a way that condensation risk is avoided. Not all combinations work. If your question is a reference to the flash-and-batt method, you should read this article: "Flash-and-batt insulation."

And remember -- if you are talking about a sloped ceiling rather than a wall, any air-permeable insulation (including cellulose) can only be installed if there is a ventilation gap between the top of the insulation and the underside of the roof sheathing. Omitting the ventilation space is a code violation.

My 1960's Cape Cod has the same sloppy traditional insulation in the devil's triangle, but the sloping ceiling is filled with blown-in fiberglass, with no baffles or any air vent channel whatsoever. The house does have soffit vents, ridge vent and gable vents. Also the space above the stairs veiling has little to no insulation and a small gap to the space above the horizontal ceiling is visible. It seems like this setup is original. Should I worry about the lack of proper ventilation? I just moved in a few months ago and I noticed ice dams, but there's no visible damage/humidity on the roof deck visible in the devil's triangle area.

What is your IECC climate zone?

What type of roofing material? Color= ?

How deep are the rafters/insulation in the insulated sloped area?

In zones 3 or lower the risk to the roof deck is pretty low in zones 6 & higher the risk can be substantial.

Some mitigating factors would be low insulation depth (say 3.5" deep insulation in 2x4 rafters/trusses), dark roofing & reasonable exposure to sunlight, all of which increases the average wintertime temperature of the roof deck, or slate/wood shingles, which allow drying of the roof deck toward the exterior.

Factors that raise risk are light, reflective roofing (limits the drying effects of the sun), membrane roof or impermeable membrane underlayment (eliminating all drying toward the exterior), heavy shading from landcape, adjacent buildings or trees, limiting the drying effects of the sun.

When it's time to re-roof, consider installing a layer of exterior insulation with performance sufficient to deliver dew point control at the roof deck in the fiberglass insulated portion.

Thank you for the reply. This is new territory for me.

Yes, the contractor recommended removing the plaster ceiling on the sloped portion in order to spray foam. It sounds like the correct method, but will be too expensive to remove 2, 60 foot lengths and put back together.

You are also correct that the second contractor will be blowing in dense packed cellulose to the rafter space behind the sloped ceiling. I will have to find out how they propose to vent it. However, after doing more research, it seems like the this suggestion is counterproductive. The closed cell foam would be used to created an unvented attic but then the blown in cellulose would allow venting. So am I throwing good money after bad by spray foaming only portions of the roof? Should I just plan for a conventional vented attic?

(Do you provide consulting? I'd love to talk to you about this)

Thanks so much for your feedback!

Brett

Brett,

1. You don't want to use dense-packed cellulose in the sloped portion of the roof assembly without a ventilation channel that connects with outdoor air at the bottom and a vented attic at the top.

2. If you are creating an unvented roof assembly above the triangular attic (the attic behind the kneewall), then there won't be any room for vent channels because the rafter bays will be filled with spray foam.

Q. "Should I just plan for a conventional vented attic?"

A. There is nothing wrong with a conventional vented attic. But you still need a plan to insulate the sloped ceiling. If your construction budget won't allow for removal of the plaster and installation of a new drywall ceiling, the usual solution is to apply for a construction loan at your local bank.

Hello Martin,

I am facing the same configuration and challenges as Brett in a 1938 cape-style home in Portland, Oregon, Zone 4c.

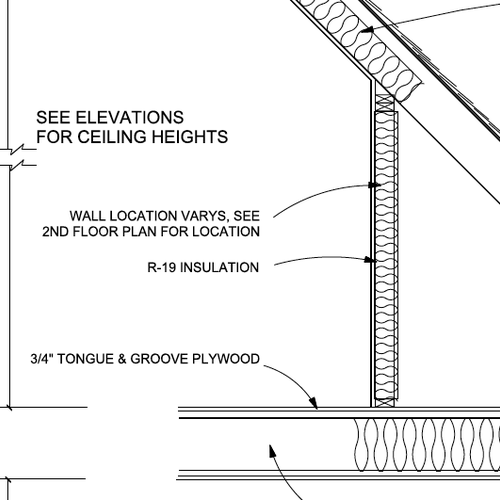

All of the contractors which provided quotes have proposed blowing in dense-packed insulation (either fiberglass or cellulose) in the sloped sections of ceiling above the knee walls up to the flat portion of the attic. There will first be rigid foam blocking installed at the bottom of these channels. These sections are short - between 2 and 4 feet at most, depending on the room.

Each knee-attic/triangle area will then become its own passively ventilated space with a single "mushroom vent" in the roof. There are four knee-attic spaces and range from appx 50 to 100 ft^2.

The floor joist blocking will be installed as described in your article and the space under the decked knee-attic blown with dense-packed insulation and the area over the decking topped to reach R-38, while the knee walls themselves receive R-15 batts and a vapor permeable air barrier. Doors are to be weatherstripped/insulated/detailed.

This is obviously a mix of R values and methods, but the air barrier seems solid (I am air sealing all of the electrical outlets and there are no utilities in any of the spaces), even if the insulation does not meet code in all locations.

The rafters are 2x4 so there is no way to provide code-required insulation with or without a vent channel (without re-roofing with rigid foam above).

This approach seems reasonable to me (although there is some risk of condensation in the sloped sections of ceiling) and appears to meet the local quasi-governmental organization's specifications for rebates, etc., The Energy Trust of Oregon (Specifications Manual at https://www.energytrust.org/incentives/self-installed-insulation/).

The risk of condensation seems very low as these short sections of roof can dry to both the inside and out as they will not have air barriers installed.

So, my questions are:

1. In relation to your point "1." to Brett above - why not put dense-packed cellulose insulation in these sections? Is it only because it does not meet (new construction) code?

2. What are your thoughts on this proposal?

3. The alternative I am considering is to bring the spaces inside the envelope as you outline, but without a ventilation channel due to how shallow the rafters are. I was thinking to do "cut/cobble and batt" in the roof of these spaces (instead of "flash and batt"), and still dense-pack cellulose under the decking as a method of insulating the Band Joist (even though it is a little bit Belt-and-Braces, it seems prudent to do the best to insulate almost over the top plates). This would involve building out the rafters as outlined, and planned for two layers of 1.5" XPS against the skip sheathing (OSB decking is installed over that), with seams taped and edges foamed. Then fiberglass batts below to reach R-38 and finally a vapor permeable air barrier showing to the inside. How does this strike you as an alternative to the flash and batt method?

thanks for all you do with the forum, this has been a fantastic place to learn.

Kevin

From ETO document:

AT 2.4—Vented Vaulted Ceilings

If insulation is added to a vented vaulted ceiling, a 1” air space shall be maintained above the insulation. Each cavity shall have an upper and a lower vent.

AT 2.5—Unvented Vaulted Ceilings

If insulation is added to an unvented vaulted ceiling, it shall be filled with tightly packed insulation.

Kevin,

Anyone trying to insulate an older house soon learns that it can be difficult to do a good job. Compromises are often necessary. It's often necessary to settle for lower R-values than desired, or riskier assemblies than optimal. I get it.

Only you can balance these risks and costs to determine the outcome you're comfortable with.

Many insulation contractors advocate the use of dense-packed cellulose without any ventilation channels for short sections of sloped roof. Although this approach is somewhat risky, most such jobs don't result in moisture disasters. Your mileage may vary.

I give advice over the internet, and I'm conservative. Lots of cathedral ceilings fail, and moisture disasters (and ice dam disasters) are a dime a dozen. I tend to advise homeowners that it's best to do the job right, even if it's expensive.

Here are the risk factors for failure: the colder the climate, the riskier the approach you describe. The more humid your home's interior, the riskier the approach. Your roof may be saved by the fact that your climate is relatively mild, and by the fact that you will try to keep your interior relative humidity in a reasonable range. (You will do that, won't you?)

A couple of points:

1. You wrote, "The risk of condensation seems very low as these short sections of roof can dry to both the inside and out as they will not have air barriers installed." Are you sure that the roof assembly can dry to the exterior? It certainly can't dry to the exterior if you have asphalt shingle roofing or metal roofing, or if your roofer used synthetic roofing underlayment. (Most brands of synthetic roofing underlayment are vapor-impermeable.). Perhaps your house has cedar shingle roofing or concrete tile roofing -- if it does, you're right about the exterior drying. Note as well that the lack of an air barrier makes the assembly more risky, not less risky. The main way that moisture enters the assembly is through air leaks, so you want an air barrier.

2. One of the big problems with a roof assembly that consists of dense-packed cellulose in 2x4 rafters is the low R-value. Another problem is the thermal bridging through the rafters. Low R-value and thermal bridging can contribute to ice dams.

Whatever you choose to do, I wish you good luck.

Thank you for your reply. It has been a lot of fun to study options for retrofitting this old house, but it is additionally maddening at times - no answer is 100% correct in retrofitting - as you said.

1. After I wrote my question I realized that I was incorrect regarding the drying of the roof to the outside. As you point out, the assembly cannot dry to the exterior due to the asphalt roofing.

These short sections could dry to the inside (through the plaster) and (subject to the ability of the cellulose to support it) upwards to the flat open section of the attic in each rafter channel. There are no penetrations in any of these sections, so the only moisture that will enter would be through the plaster, or driven inwards through the roof. Both seem low probability/quantity.

2. I will read further on ice dams. We rarely get snow or freezing temps with rain, but we just had such an event this past weekend and it got me thinking about (and looking at) ice dams.

3. Can you offer any thoughts regarding my third point - the possibility of bringing the knee-attic spaces inside the envelope with an unvented approach? I read further last night in your post https://www.greenbuildingadvisor.com/article/cut-and-cobble-insulation

and you clearly do not recommend this, and it sounds like you have become more conservative regarding this over the years, presumably due to further evidence of issues from the field? I'm wondering if dense packing under the floor to reach the rim joist and further prevent moisture from entering the knee space will help mitigate the risk of moisture entering the unvented roof (assuming that the spray foam seal on the XPS failed due to expansion/contraction). Does the presence of skip sheathing in addition to the OSB overlayment increase or decrease the risk of failure?

thanks again!

Kevin

Kevin,

Q. "Can you offer any thoughts regarding my third point - the possibility of bringing the knee-attic spaces inside the envelope with an unvented approach?"

A. Bringing the kneewall attic (the triangular attic behind the kneewall) inside the home's thermal envelope is the best approach. If you want to create an unvented insulated roof assembly above this attic, and you are working from the interior, you should install closed-cell spray foam on the underside of the roof sheathing. The two most common ways to do this are (1) to hire a spray foam contractor to do the work, or (2) to use two-component spray foam kits (available at most lumberyards and building materials supply houses).

As you discovered by reading my article, I don't recommend using the cut-and-cobble approach for unvented roof assemblies. That approach is associated with moisture problems.

Dear Kevin and Martin: First, I agree with Martin that an unvented attic is the best approach - by far - for a home like yours. This is what we did with our previous home, an early 50s Cape with inaccessible knee walls. Spraying foam under the roof deck also air seals the surface and delivered a significant improvement in our home heating bills the next winter -- before we made a bunch of additional upgrades. Second, I strongly recommend hiring a spray foam contractor. Spraying lots of foam inside an unventilated space is risky. At a minimum, you would need a professional level mask with cartridges designed for that type of hydrocarbon vapor. Many professionals go a step further with an air-supplied mask/helmet that delivers fresh air from the exterior. Finallly, a number of new closed cell foam products have been released with new blowing agents that have very low GWP (Global Warming Potential), e.g. Icynene ProSeal HFO and Gaco OnePass Low GWP. This also means reduced odor following installaiton.

I hope this is helpful,

Mark

Mark,

Thanks for you comments. One clarification: I never said that "an unvented attic is the best approach." Where a vented approach is possible, I usually prefer a vented approach.

Martin and Mark,

Thank you both for your comments and input, it is very much appreciated.

I agree with Mark; I had our rim joist spray-foam insulated several years ago - the efficiency of a contractor setting up and getting the job done is worth hiring one - before even considering that their safety protocols are already in place.

I am going to try the unvented approach for one of the knee attic spaces, although it will be a cut and cobble approach. I understand the risk, but a) I will be doing the work myself, b) it is a small attic and c) we have not seen any moisture issues in our 1930 house, even though there were foil-faced batts under the rafters and on top of blown in cellulose for years before I removed it all. I think the risk of moisture-related damage is quite low, even though the house will become tighter with additional insulation and (for the first time) wall insulation! Yea :) I have previously done a bunch of air sealing and the balance will be done in this project.

Given time and cost constraints the other 3 spaces will be as recommended by the contractors - they will remain outside of the envelope. Perhaps if I had started my research earlier I might have been able to do the flash and batt method and bring them in the envelope, but in either case I must weight the risks and costs...

thanks again.

Kevin

I also have 1960 Cape Code style house, with a finished attic with knee walls. We just got the entire roof redone. Currently the kneewall triangular attic is outside the conditioned space. Batt fiberglass on the outside of the knee walls, and the floor of the triangular attic. Also, there are insulation batts in the rafters themselves. However, many of rafter batts are either hanging down, or have fallen down. These go all the way up to the roof peak, but either tore in half when the lost support, or they just used two separate pieces (one for the top half and one for the bottom half rafters).

We have gable vents on both ends of the house, so top attic is vented. I want to reattach/replace the rafter batt insulation that's hanging/fallen in the kneewall attic, and then put in 1 or 2 inch XPS or poly iso over the rafter batts. My intent is to bring the kneewall triangular attic into conditioned space.

Do I need to remove the kneewall batts both on the floor and on the kneewall itself?

Also, there are no soffit vents, as the roof assembly terminates at the exterior wall. Will there be a problem with my approach in terms of heat buildup on the lower part of the roof deck? Or given that mineral wool/fiberglass allows air to pass, then in theory, the hot air from the lower roof deck will eventually make it's way to the top vented attic? I'm assuming that air will somehow get into the lower roof assembly from the outside.

Cool Viper,

If it's impossible to provide a vent channel in each rafter bay between the underside of the roof sheathing and the top of your fiberglass batts (an option that requires soffit vents), then your only options are (a) install rigid foam insulation on the exterior side of your roof sheathing (which you aren't going to do because you just replaced your roofing), or (b) install closed-cell spray foam between your rafters.

Does anyone have details on building the subfloor for the "devil's triangle"? The issue is that that area is not only awkward with trusses intersecting the floor, but the lumber in that portion isn't the same size as the rest of the truss. Is the best approach to sister the trusses with the same sized lumber as the rest of the trusses, add blocking to form a rectangle for each bay, and then cutout one panel per bay with notches around the trusses? Or would it be better to run long lengths of lumber on top in the opposite direction so that the cumulative height matches the rest of the floor? This also seems difficult to air seal well, which is important to separate the garage below.

I've got a knee wall situation in which I have attic trusses with 2 x 12s until the knee wall where the truss drops down to a 2 x 4. Technically that 2 x 4 area in the devil's triangle isn't deep enough for the R38 insulation. But one Contractor told me he'd just "twine" them to hold them in place. On the other hand we planned on un-faced batts with a 4 mil VB. Can't figure out how we're supposed to run 4 mil in that area? Is there an acceptable way to run those R38s all the way down without a bunch of extra framing? Or another solution? I don't want to insulate the knee wall.

Log in or become a member to post a comment.

Sign up Log in