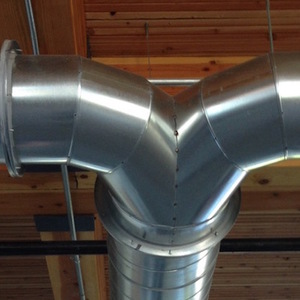

Image Credit: Energy Vanguard

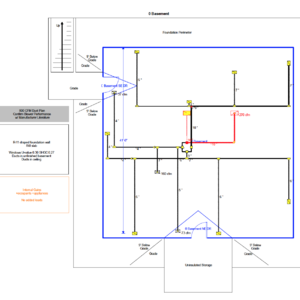

Image Credit: Energy Vanguard This duct design shows the layout of a duct system, including the fittings and duct sizes.

Image Credit: Energy Vanguard This table shows the equivalent lengths of various types of rigid elbows.

Image Credit: ACCA Manual D This screenshot from RightSuite Universal shows total effective length for a particular duct design.

Image Credit: Energy Vanguard

Today I’m going to explain an important concept in one of the most popular ways of doing duct design. I’ve been writing a series on duct design over at my blog and began with a look at the basic physics of air moving through ducts. The short version is that friction and turbulence in ducts results in pressure drops. Then in part 2 I covered available static pressure. The blower gives us a pressure rise. The duct system is a series of pressure drops.

We can divide the pressure drops into two categories: those resulting from the ducts and fittings and those resulting from all of the components that aren’t ducts and fittings (e.g., registers, grilles, filters…). When we subtract the non-duct/fitting pressure drops from the rated pressure rise (total external static pressure) of the blower, we get the available static pressure. That’s the total pressure drop we have available for the ducts and fittings and is what sets our duct pressure budget.

What we want to get out of this in the end is the proper duct and fitting sizes. We have a certain amount of available static pressure to use up. If our ducts are too small, we can end up with either too little air flow in the case of a fixed-speed blower (PSC, which stands for permanent split capacitor), or we get the air flow but use too much energy with a variable-speed blower (ECM, which stands for electronically-commutated motor). The first step in finding the proper duct and fitting sizes is to find the total effective length (often called equivalent length), the topic of today’s article.

What is effective length?

Length is length, right? Why do we need something else called effective length? The answer lies in fittings, those duct components that allow you to take air out of a trunkline, split a single duct into two runs, turn the air, and more.

For straight duct sections, pressure drop depends only on the length. Well, that’s the idea anyway. If we use flex duct and don’t pull it tight, the pressure drop will be greater than if it were pulled tight. Texas A&M did a study on the effect of flex duct not pulled tight and the results are astounding. In my article on this research, I showed from their results that a 6″ duct moving 110 cfm when pulled tight will move only about 70 cfm with 4% linear (longitudinal) compression and about 40 cfm or less at 15% compression. (I’ll write more about the effect of different duct types in the HVAC design process later in this series.)

For our purposes here, I’m going to assume that the ducts we’re using are either rigid metal or flex pulled tight. ASHRAE now has a duct calculator with options for 4%, 15%, and 30% longitudinal compression, but that’s not for use in designing duct systems. It’s to show how bad existing systems are if the flex isn’t pulled tight or to scare installers into pulling it tight.

So, we’ve got straight sections of duct with their pressure drops depending on the actual length. And then we’ve got fittings. Each fitting — whether it’s splitting the air flow, reducing the duct size, or turning the air — will cause a pressure drop. In the duct design process, however, it’s more convenient to categorize these pressure drops by the length of straight duct run that would create the same pressure drop. And that, my friend, is the definition of equivalent length.

But wait, you say! You were talking about effective length and now you’re talking about equivalent length. What’s going on here? ACCA’s Manual D uses both terms, although without clearly distinguishing them. From the context, though, here’s what I’ve surmised: The effective length is the combination of actual lengths of straight duct and equivalent lengths of fittings. Most people use the term equivalent length for both, though.

Adding up all the lengths and equivalent lengths

Before sizing a duct system, we have to lay out all the ducts. Below you can see an example of one we did recently. It shows the duct layout with all vents, fittings, air flows, and duct sizes. To find those duct sizes, the software we use (RightSuite Universal) calculates the effective length of the most restrictive run. From the return grille to the supply register in that run, it adds the lengths of the straight runs and the equivalent lengths of all the fittings.

Each fitting we choose has an effect on the pressure drop and total effective length (TEL). We can look them up in tables, like the one below showing equivalent lengths for various elbows.

The main variables we have to work with for this fitting type are:

- Radius of the turn (R)

- Diameter of the duct (D)

- Number of pieces

- Round or oval

When we choose fittings, we pick them based on what’s commonly available at HVAC supply houses. We also go a little conservative here because we’re doing third party HVAC design and don’t have control over the installation. For example, most of the elbows used in actual duct systems have 4 or 5 pieces. We often choose a 3 piece elbow in our design, though, because it gives us a little slack in the design. If the installer uses the 4 or 5 piece elbow instead, with 5 feet less equivalent length, the actual duct system will be less restrictive than the designed duct system, at least in that part.

The total effective length (TEL) is the sum of all those fitting equivalent lengths plus the lengths of straight duct. If you’re doing it by hand, you have to go through the process for every single duct run. Then you choose the one that has the greatest total effective length. You do NOT use the sum of all the ducts and fittings.

The last image below is a screenshot from RightSuite Universal showing the total effective length in one of our designs. The lengths of straight sections of duct add up to 36 feet for the supply side and 13 feet for the return side. The fittings add up to 290 feet and 85 feet respectively. This is typical. Fittings dominate when it comes to using up the available static pressure, so you have to choose them carefully. Just take a look at that table of elbows above. If you choose well, you can be at 10 or 20 feet of equivalent length. If you choose that smooth mitered elbow, however, you end up with 75 feet.

The next step

Once you lay out your ducts and choose your fittings, you have a total effective length. But here’s a little caveat: Those equivalent lengths for fittings depend on the velocity of the air, too, and it’s not a linear relationship. There are corrections for that effect, which, as far as I know, aren’t currently built into the software.

To summarize:

- The blower creates a pressure rise to move air through the ducts.

- It’s rated for a certain amount of air flow at a specific total external static pressure.

- The ducts, fittings, and other components cause pressure drops.

- Subtracting the pressure drops for all the things that aren’t ducts or fittings from the total external static pressure yields the available static pressure.

- The available static pressure is the pressure drop budget you have to work with when designing the ducts.

- Each fitting has an equivalent length that equates its pressure drop to an equivalent amount of straight duct.

- When you add up the equivalent lengths of all the fittings and then add that number to the length of the straight sections in the most restrictive runs in the return and supply ducts, you find the total effective length (TEL).

The next step in designing a duct system would be to take your available static pressure and figure out what friction rate you have to work with in sizing the ducts.

Allison Bailes of Decatur, Georgia, is a speaker, writer, building science consultant, and the author of the Energy Vanguard Blog. You can follow him on Twitter at @EnergyVanguard.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

0 Comments

Log in or create an account to post a comment.

Sign up Log in