Image Credit: GreenBuildingAdvisor

During the winter months, wall sheathing is usually cold. Cold sheathing is risky, since it tends to accumulate moisture during the winter. Unless the sheathing can dry out during the summer months, damp sheathing can rot.

Cold sheathing can get wet from two directions. It can get wet from the exterior, due to leaks through defective flashing or a poorly detailed water-resistive barrier (WRB). It can also get wet on the interior, due to a phenomenon traditionally called “condensation,” but more accurately called sorption. (As building scientist William Rose likes to say, “Capillary materials do not exhibit condensation at the dew point.”)

Most wood-framed walls are somewhat leaky. Interior air can leak into wall cavities through cracks around electrical boxes and cracks between the drywall and the wall’s bottom plate. When the warm air reaches the cold wall sheathing, one of two things usually happens: frost can form on the sheathing, or, at temperatures above freezing, the sheathing (which is hygroscopic or “sorptive”) can gain moisture from the air. (The source of the moisture taken on by sorption can be either interior or exterior moisture; for further details on moisture sources, see Bill Rose’s posted comment below.)

Why doesn’t every cold-climate wall have rotten sheathing?

Most cold-climate homes have wall sheathing that gains moisture every winter. Usually, however, the wall sheathing doesn’t rot, because:

- wood doesn’t rot when it’s cold, and

- the sheathing dries out every summer.

Building components can survive occasional wetting, as long as the rate of drying exceeds the rate of wetting. If, on an annual basis, the wall dries more than it gets wet, it will probably be okay.

Probably — but not necessarily. In many areas of the U.S., OSB-sheathed walls have failed at an alarming rate. A combination…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

71 Comments

OSB

Martin,

The state of MN did some test walls in various parts of the state, some with OSB. I asked about the results 10 months ago and have heard nothing. Maybe with your clout you could get the test results.

Response to Doug

Doug,

Do you have any idea which agency, university, or researcher was involved?

MN assembly studies

Doug and Martin,

There are researchers at the University of Minnesota who have conducted wall assembly studies both in hygrothermal modeling and physically at the Cloquet Residential Research Facility.

Two names I know are Louise F. Golderg Ph.D and Patrick H. Huelman. Patrick's affiliation at the UofM is the Cold Climate Housing Program in the Department of Bioproducts/Biosystems Engineering. Dr. Goldberg's program was fazed out I believe but I think she still is a researcher/ professor at the University but also heads a consulting firm.

Martin I'll email you a .pdf of a study that I have although it is not specifically about OSB. I would think the researchers of this study could help you track down the OSB study.

Good topic, good advice

Hello Martin,

Interesting question. I found John Straube’s response to be quite good.

OBS is produced under conditions of high temperature and pressure. So I figure that, over time it will relax. I imagine a stack of sheets, stickered, and placed in a park pavilion protected against rain and sun. What would the stack look like after 5 years? Most people say it’ll be just fine. After 500 years? Most say it’ll go to mush. After 50? Most people go hmmm… There are wide differences in the product of course, so there is no single answer on the 50 year question.

I recommend someone conduct a survey of unheated outbuildings sheathed with OSB. Any OSB on an unheated outbuilding, in any climate, assuming no undue moisture loads from the interior, should paint a pretty good picture of how the sheathing will hold up on a well-insulated wall. And it may do well for many decades, I don’t know.

Exterior sheathing gets wet by virtue of getting cold. (You assign the “Cold-wet; warm-dry” quote to Joe Lstiburek. It’s my quote; I’d let Joe have the credit if he wanted it, but I’m not sure he wants it. He’d probably have come up with it long before I did if it accurately captured his thinking.) Your discussion of “condensation” leaves a lingering impression that wetness in cold sheathing materials comes from the inside, that is, from the high-vapor-pressure side (Northern bias throughout). Actually it comes from both sides, and predominantly from the side it’s closest to—the outside. There are ways to tweak both steady-state and transient analysis to answer the question of where the water comes from. We’ll have to leave that as an exercise.

The advice you give here is good. Of course.

Credit where credit is due

Bill,

Thanks for your comments, which are always welcome. Your point that moisture absorbed by OSB during the winter is more likely to originate from the exterior than the interior is an important one.

I have corrected the attribution for the "Cold, wet; warm, dry" quote. Thanks for helping set the record straight.

Would a 'breathable'

Would a 'breathable' sheathing solve the problem of moisture forming on the back of the sheathing? I was aware of a product used in UK and Ireland, Panelvent was the name. I do not know the permability but, reading up on the product, it seems that using this type of sheathing would possibly help. To be honest, I have no idea if this product or any similar is available here in Canada or US.

Similarly, would the breathing barrier called Membrain, by Certain Teed, used on the inside also help?

http://www.excelfibre.com/building/products4.html

Response to Ray Smith

Ray,

I'm not familiar with Panelvent, which is made from wood waste and wax. It is possible that Panelvent shares some of the same durability concerns as OSB.

In general, though, you are right: highly permeable sheathings dry faster than impermeable sheathings. That's one reason why diagonal board sheathing -- and to a lesser extent, plywood -- are preferable to OSB.

Although there's nothing wrong with MemBrain, its use on the interior of a wall won't solve the "cold sheathing" problem.

air barriers

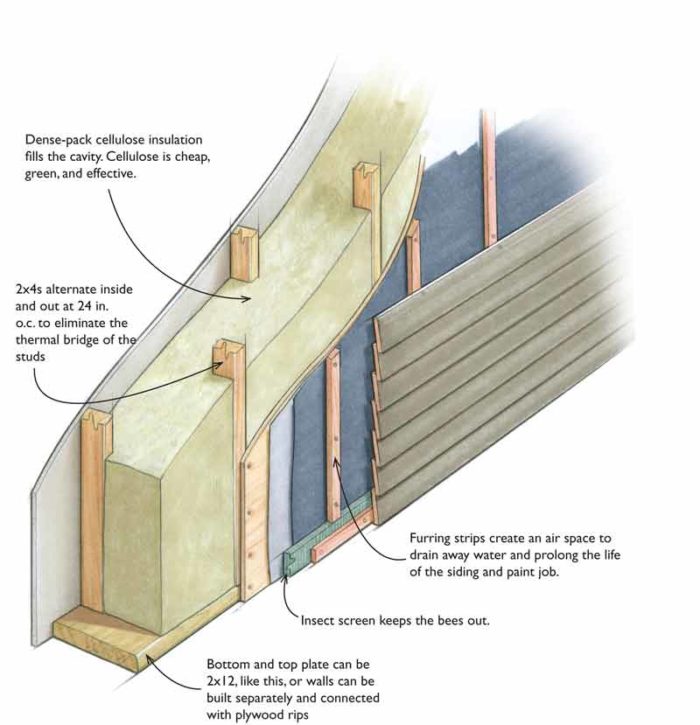

Just curious about the schematic at the top of the article and air barriers.

I'm assuming the sheetrock is intended as ADA.

Is there no exterior air barrier? Or is the plywood taped? What are the two layers of fabric between the sheathing and the rainscreen furring -- housewrap and ....?

Thanks.

Joe W.

Advantech

How long will Advantech sheathings last?

How much formeldihyde is in Advantech?

Why Sheath? use a diagonal brace.

This post points to a Bruce Brownell house being superior to 99% of homes built since Bruce started his Alternative Energy Home buildinng business.

a non mouse & god

Response to Joe W

Joe W,

Every house needs an air barrier. It is possible to establish the air barrier at the interior drywall, or at the exterior sheathing, or (perhaps) using housewrap. For more information on air barrier options, see, One Air Barrier or Two?

I'm not sure the intention of the artist who drew the detail on this page, but many builders install two layers of WRB -- for example, asphalt felt over housewrap. The idea of two layers of housewrap is to provide more protection against wind-driven rain.

Drying Out

Thanks. Great article. Here's some more convincing evidence that if you want sheathing that is permeable and will allow your walls to dry out, plywood is definitely better than OSB:

http://docs.google.com/viewer?a=v&q=cache:rCi8T00U63IJ:www.indagators.com/private/files/OSB_Swells.pdf+osb+failures&hl=en&gl=us&pid=bl&srcid=ADGEESh0xW3325eCugwOmrb0IwH1MhwRsN4Pid_YHRR4tA2llUUXLR_93UGOJaDqENfFAApBsjXF3Ea_ZKDNEPdVLyGdi_oMlWOYLTQQ4WJR0gweD9wd3IKoYY39Py_DFki1r1Rhh023&sig=AHIEtbTAQBb5fhs46ClOLNhzTCKBYStvcg

Brett.... ?

OSB is perfect for short term use... 20+ year homes that are to be ripped down after that... it's junk imhgo go without wood sheathing it's not needed.

Ventilation requirements

Martin, thanks for the article, this could end up being an important issue.

Could you get John's opinion on how much drain space & ventilation is enough?

Is using a spacer material like Cedar Breather with a 1/4" gap helpful, or not that helpful?

Is it important to create openings at top and bottom of the drain cavity for air to flow through, or is just the gap good enough?

Any suggestions on how to ventilate 20-25' vertical spaces behind masonry veneer or stucco, if it's important to do so?

Thanks for the article, this could end up being an important issue.

Response to Doug

Doug,

Q. "Could you get John's opinion on how much drain space & ventilation is enough?"

A. Most rainscreen gaps are between 1/4 in and 3/4 in. Any gap in that range will provide very significant benefits. You'll probably get slightly faster drying with the larger gaps, but I don't want to overemphasize the performance differences between 1/4 in. and 3/4 in. You might want to read an article by Jonh Straube's colleague, Joseph Lstiburek: "Mind the Gap."

Q. "Is using a spacer material like Cedar Breather with a 1/4" gap helpful, or not that helpful?"

A. It's definitely helpful. Cedar Breather counts as a rainscreen gap in my book.

Q. "Is it important to create openings at top and bottom of the drain cavity for air to flow through, or is just the gap good enough?"

A. Ideally you have air inlets on the bottom and air outlets on the top. That encourages ventilation. If you forgot the air inlets and outlets, there are still many benefits to the rainscreen gap, but you won't have the same ventilation drying effect.

Q. "Any suggestions on how to ventilate 20-25' vertical spaces behind masonry veneer or stucco, if it's important to do so?"

A. Any installation of brick veneer is supposed to include an air gap between the bricks and the WRB. Weep holes at the bottom of the wall provide air inlets. As long as you don't block the air gap at the top, you've got a ventilated cavity.

The "Mind the Gap" article has a discussion of stucco details. One of my upcoming blogs will address air gaps behind stucco in more detail.

barn style homes

Martin,

would it be best to spray foam insulation right up against the metal or how would you suggest doing it? Or anyone else have a better suggestion of insulating 6" walls with drywall interior.

Response to D. Sayer

D. Sayer,

You didn't provide enough information for us to understand your questions. What metal are you talking about? Are you talking about galvanized steel panels used as siding?

Is this a retrofit job or new construction?

Please describe your planned wall assembly in detail. It's also a good idea to tell us your location or climate zone.

Most houses include wall sheathing. Does yours?

OSB on outbuildings...

Bill Rose wrote:

Wouldn't OSB-sheathed roofs over vented attics provide similar conditions? Surely we have OSB sheathed roofs over vented attics in every climate zone in North America by this point.

Response to John Semmelhack

Yes, OSB roof sheathing over vented attics makes a rather good test case. Roof sheathing goes through wider cycles of temperature than wall sheathing does. On a clear night, the sheathing is very cold--colder than any other part of the building. During the day it is hotter. For central Illinois, the net of these two effects is that roof sheathing is warmer than most other building parts, so it may be somewhat drier overall. The effect of the daily cycling may not penetrate too deeply into the OSB.

Still, it's a pretty good test case. I don't go into that many attics these days, but I don't see much swayback in roofs from the street, suggesting it's holding up pretty well. Other observations are welcome.

Response to John Semmelhack

John,

You're right that OSB roof sheathing above an unconditioned attic can absorb moisture every winter. However, the OSB roof sheathing will dry much faster than OSB wall sheathing, for two reasons:

1. There is more warming from the sun, and

2. There is usually no insulation on the attic side to slow drying.

OSB Roof Sheathing

I can spot the butt joints on the OSB roofs when 3 tab shingles are used, this tells me the edges have taken on some moisture.

cold osb

Excellent article! You considered and answered many questions for me. I'm surprised that no one has mentioned SIPs , however. They seem like an excellent example of what you're talking about. I know there have been some problems on SIPs roofs with air exfiltration condensing on the roof deck and rotting. Is this because the roof can't warm enough to overcome the moisture, or more likely that the condensed moisture is trapped? I realize that preventing warm moist air from getting to the deck is the first defense, however, if we're describing frost, it seems that you need to either make sure moisture can't get trapped or put a layer of rigid foam over the osb, this begins to get tedious.

OSB just seems so vulnerable over the long term, it hard to imagine it staying strong over years of repeated wetting/drying, I imagine those fibers just getting looser and looser. One writer mentioned Advantech, which seems much stronger and moisture resistant than standard OSB, but also seems like overkill at 3/4", Also would north walls be particularly vulnerable to this effect due the relative lack of drying potential?

thanks

Response to David Lanfear

David,

The most significant cluster of SIP failures occurred in Juneau, Alaska. There are many resources on the Web describing these SIP failures, including:

http://www.sips.org/content/technical/index.cfm?PageId=161

http://www.greenbuildingtalk.com/buildcentral/sip/2001-10_juneau.pdf

http://www.buildingscience.com/documents/insights/bsi-036-complex-three-dimensional-air-flow-networks

The rot in Juneau began at the exterior OSB facing near the seams. There were two mechanisms involved:

1. In some houses, moisture in exfiltrating air condensed on asphalt felt. These houses had seams that were not airtight.

2. In other houses, convection loops through gaps and channels in the SIP seams brought warm humid air in contact with cold materials in the seam area, even when no air was exfiltrating.

I don't know why 3/4-in. sheathing is necessarily overkill. Here in New England, most houses were sheathed with 1-in. or 3/4-in. boards, at least until the late 1940s or early 1950s.

Letting the moisture out

If plywood is a great improvement over OSB on a thick double stud wall, would

fiberboard be even a better choice?

Response to Bryan

Bryan,

Fiberboard can be a very good option. As you point out, it is very vapor-permeable, and it provides some racking resistance (bracing).

However, it doesn't hold a nail like plywood.

OSB sheathing

Great discussion. Thank you. What do you think about a 2x6 stud wall with 1" closed cell foam on the outside as sheathing, taped, two inches of closed cell foam sprayed against the inside of the foam sheathing, 3 1/2" of cellulose, and either 5/8" sheetrock for sheer or 1/2" OSB sheer with 1/2" sheetrock on the inside of the stud wall? The idea is to keep the insulation on the outside with the dew point somewhere in the insulation and the sheer on the inside. My engineer is letting me experiment with this idea on a simple custom.

Response to Anders Lewendal

Anders,

You don't mention your climate, but your suggested R-31 wall should work in just about any climate, so I think you are fine. (I'm not sure what type of foam sheathing you intend to use; all three types of foam sheathing -- EPS, XPS, and polyiso -- are closed-cell foams.)

SIS instead of OSB

In our most recent project we used the DOW Structural Insulated Sheathing product, taped at the seams, instead of OSB/Tyvek. We built with 2 x 6 exterior walls and used dense pack cellulose insulation. Our exterior consists of thin cut stone/efis up front and hardieplank around the rest of the house. Does anyone foresee any long-term moisture issues? If so, any remedies?

SIP walls

So, does this mean a house build with SIPs is vulnerable to OSB failure? From the discussion, it seems that one solution is to put rigid foam on the outside of the SIPs to move the dew point. How thick does that layer need to be in the mid-atlantic area to be enough to prevent the OSB from turning to mush?

I asked a question on here a couple of weeks ago about adding rigid foam on the exterior of SIPs and the recommendations I received were to not to sandwich OSB between two layers of relatively impermeable foam, due to the slow drying potential of EPS.

https://www.greenbuildingadvisor.com/community/forum/passivhaus/18736/xps-or-eps-foam-outside-sip

So, which one is right?

Response to Vic

Vic,

It's impossible to answer your question without knowing your climate. It's also important to know the thickness of the Dow SIS that you used.

Dow SIS comes in two thicknesses. The 1/2 inch panels are R-3, while the 1-inch panels are R-5.5.

To answer your question, you need to refer to the table I included in a different blog, "Calculating the Minimum Thickness of Rigid Foam Sheathing." From that table, you will see that R-3 foam sheathing is insufficient to keep you out of trouble with a 2x6 wall unless you are in a warm climate zone -- Climate Zone 1 through 4 (but not Marine 4).

If you have the thicker SIS, with an R-value of 5.5, your 2x6 wall will be OK in Marine Zone 4, but not in a colder climate.

Dow SIS is a two layer product consisting of polyisocyanurate foam bonded to a composite material made out of recycled cardboard. We don't have enough experience yet to determine how that fibrous layer holds up if it gets wet on a regular basis.

Response to Roger Lin

Roger,

Q. "Does this mean a house build with SIPs is vulnerable to OSB failure?"

A. Some experts are worried about the long-term durability of OSB facings on SIPs, especially the exterior facing. (The interior facing stays warm and dry, and is therefore at less risk.) There have already been SIP failures in Juneau, Alaska.

If I were building a SIP home in a cold climate, I would certainly include a ventilated rainscreen gap between the SIP and the siding, to encourage rapid drying. And I would avoid any siding (like stucco) that dries slowly.

RE: SIS instead of OSB

Martin, thanks for the reply. We are in the mid-atlantic, DC area. I believe its the northern part of climate zone 4. We used the 1/2" R-3 SIS.

Follow up question

Thanks Martin! Yes, I did hear about the Alaska failures. The other question I had was whether sandwiching OSB between two EPS foams is risky. Thanks

Second response to Roger Lin

Roger,

That question is hard to answer.

If the exterior OSB is dry when it is covered with another layer of EPS, then adding the extra foam should keep the OSB warmer and dryer than it would otherwise have been. However, it also makes it hard for it to dry out in the future.

My guess is that adding another layer of EPS will make the OSB last longer than it would have otherwise. But the bottom line is, we don't really know how long OSB is going to last. So I guess my conclusion is, "We really don't have enough data to answer your question."

Thanks Martin. I guess only

Thanks Martin. I guess only time can tell.

Exterior foam situation

Martin,

I've presently got foil faced fiberglass insulation in the stud wall and I want to add foam to the exterior. I'm in Zone 4, marine... the PNW. Will the foil facing cause me problems by inhibiting drying to the interior? Should I remove the foil? That would be a hassle, but doable.

Response to Jeff Patrick

Patrick,

My usual response to questions like yours is that you should keep your eyes peeled for any moisture problems when you remove your siding. Inspect your sheathing carefully. If you sheathing is dry and sound, with no signs of dampness or rot, proceed with your plan to add exterior foam.

If there are any signs of dampness or rot in your sheathing, though, it's time to put on the brakes. At that point you'll need to do a forensic investigation and determine the source of the moisture.

Seal the OSB?

I'm not a builder but I'm interested in the subject. I have an unheated workshop above my garage with fiberglass bats on the north side of the roof and rigid foam on the south side of the roof. The bats are covered (rather poorly) with plastic. I'm not concerned about the south side because it gets really hot between the foam and the OSB thanks to the abundance of sunshine here in Colorado. In fact I have two fans that draw that heat out during the day and blow it into the shop area. At night in the winter the temps in the shop may be in the 40s and daytime temps in the 50s or 60s.

Here is my question: would it be worth it to remove the fiberglass bats on the north side of the roof and coat the OSB with marine varnish or some other type of sealer? Thanks!

Response to Dan Russell

Dan,

The short answer to your question is No.

A couple of comments:

1. My blog is about walls, not roofs.

2. Are you worried about your OSB roof sheathing getting damp? There is probably not much reason for concern, since most garages and workshops don't generate a lot of moisture. (However, I don't know what activities you perform in your workshop.)

3. In general, the best way to address a concern about moisture buildup in roof sheathing in an insulated cathedral ceiling like the one you describe is to be sure there is a ventilated cavity between the top of the insulation and the bottom of the roof sheathing. You could also install an air barrier (gypsum wallboard) under your insulation. That will improve safety considerably compared to exposed polyethylene, which is a fire hazard.

About the Insulation

Have you ever considered rock-wool insulation. It has been used for many decades in Europe and more recently here in Canada with superior results. It is also a recycled content material from the waste of generations of industrial production - products such as Roxul are an example. I am not a rep simply a designer/builder/teacher who was fully aware of the product but had to wait some 18 years to finally have the product available in NA after researching it back in the 1980's.

In the Pacific Northwest we describe your furring space as a rainscreen and insist that it be used if we have any integrity at all.

regards

smalld

Response to Small D

Small D,

I call it a rainscreen too.

condensation in wall assemblies

I'm surprised John Straube didn't mention the report he wrote for CMHC.

http://www.cmhc.ca/odpub/pdf/66564.pdf

Response to EcoRalph

EcoRalph,

Thanks for the link. The information in the CMHC report is consistent with advice promulgated on the GBA Web site. Some interesting points from the report:

"Regardless of the vapour permeance of the materials used in a wall assembly, control of air flow through the enclosure must be provided by an effective air barrier system. Inadequate control of airflow remains by far the most significant source of condensation for both above- and below-grade assemblies. ...

"The addition of insulating sheathing controls both cold weather and warm weather condensation without the use of plastic sheeting, but the R-value of the insulation must be sufficient to control winter-time condensation for the interior humidity expected. ...

"Warm weather condensation on plastic sheet vapour barriers can occur in air-conditioned buildings with a rain-wetted absorbent cladding exposed to the sun. However, this specific and persistent combination of factors is required before condensation occurs. ...

"The study shows that above-grade walls with either polyethylene or vapour barrier paint can be made to work in Canadian environments. It also shows that the performance of either can be compromised under severe environments or without proper attention to details."

osb vs. plywood

I'm very confused by the contractors differing opinions. I have purchased a balloon frame building in New Orleans that, because of years of water intrusion needs the siding replaced and structural components replaced on both sides of the structure. Plan is to systematically remove the wood siding, make the internal repairs, sheet with OSB, install Drainwrap Housewrap with flashing system around existing windows, and install vinyl siding. Any comments are welcomed. Snyder

Response to Snyder

Snyder,

You didn't ask a question; you just invited comments.

What differing opinions are you encountering?

I used craft faced insulation

I used craft faced insulation instead of unfaced insulation and a polyethelene vapor retarder. I am located in montana. I am now finding that the craft facing is only a class II vapor retarder and I feel like I should have used the poly sheeting as it is a class 1 vapor retarder. As well as the fact that evert time I had to cut the insulation to fit stud spaces around windows and doors I now have a spot that is unfaced. I have already sheetrocked and sided and I am now wishing I had used the poly sheeting. my questions are: would a vapor retarding paint seal the sheetrock enough to eliminate issues, would installing an air exchanger remove enough moisture from the air, or am I just being overly paranoid? This is a shop space, I do heat it and like to have it at about 60 degrees. the exterior temp is regularly between 20F and -20F between november and april. most builders around here use the poly, however I was told that the faced fiberglass was the same as unfaced and poly. Any insight is appreciated in advance.

Response to Chris Wooster

Chris,

You have nothing to worry about. Vapor diffusion from the interior toward the exterior very rarely causes problems, and kraft facing is an adequate vapor retarder in any case.

It's always a good idea to seal any air leaks in your wall, especially around electrical boxes. But don't worry; your wall should be fine.

To learn more on this topic, see:

Vapor Retarders and Vapor Barriers

and

Forget Vapor Diffusion — Stop the Air Leaks!

gypsum a good air barrier?

Thank you for responding! . I have 1 more question for you: I was also under the impression that gypsum wallboard was not at all an effective air barrier. If you look at it under a microscope would it not look like swiss cheese? Thank you again!

Second response to Chris Wooster

Chris,

Gypsum drywall is an excellent air barrier. To use drywall as part of an air barrier system, it is of course necessary to prevent air leaks at the edges of drywall areas and at electrical boxes. To learn more about the Airtight Drywall Approach, see Airtight Drywall.

If you want to know whether a material makes a good air barrier, hold a piece of the material up to your mouth and try to blow through it. If you can blow through it, it isn't an air barrier. Examples of good air barriers include gypsum drywall, poured concrete, glass, plywood, OSB, and peel-and-stick rubber membrane.

Thanks again

Thank you I now am satisfied. You are a great resource and I appreciate you taking time out of your day to respond to me!

Gap over sheathing

A gap to the exterior side of the sheathing has been recommended (to allow air movement, with rainscreen, to allow sheathing to dry), using 1/4"' to 3/4" vertical strapping.

My question is where should the housewrap go, over the strapping or on the sheathing?

Where is the air barrier if we introduce air with the rainscreen?

Response to Richard Clark

Richard,

Q. "Where should the housewrap go, over the strapping or on the sheathing?"

A. Over the sheathing.

Q. "Where is the air barrier if we introduce air with the rainscreen?"

A. There are several possible locations for the air barrier. It can be at the sheathing, if the sheathing seams are taped. It can be within the wall cavities, if spray foam insulation is used. Or it can be at the drywall level, if the builder follows the Airtight Drywall Approach. For more information on air barriers, see Questions and Answers About Air Barriers.

plywood, OSB, or structural fiberboard

In rereading this post and the comments, I find that no one addresses the option of structural fiberboard sheathing as an alternative to OSB or plywood. It isn't always easy to find, but last I checked at least two U.S. companies made it, International Biltrite, and Georgia-Pacific. It has a permeability much higher than plywood (I believe the perm rating is about 15). Builders I work with don't love the product (think "buffalo board") but it isn't lost on me that when we open up old walls and find buffalo board sheathing it is always dry and I live in a very cold climate with a short drying season. Comments, anyone? Thanks, as always. I find myself going to the "musings of an energy nerd" often, and the topics are current and well researched. Thank you Martin!

Response to Rachel Wagner

Rachel,

Thanks for your excellent suggestion. Structural fiberboard sheathing is a less expensive option than diagonal board sheathing. It is a popular sheathing choice for Passivhaus builders.

Here is the full contact information to manufacturers and Web links to the products you mentioned:

International Bildrite

101 Fourth Street East

International Falls, MN 56649

218-283-3900

Manufacturer of Bildrite fiberboard

http://www.bildrite.net/sheathing.htm

Georgia-Pacific

133 Peachtree St. NE

Atlanta, GA 30303

800-839-2588

Manufacturer of Stedi-R structural sheathing

http://www.gp.com/build/product.aspx?pid=6056

I have also edited my article to include your suggestion. Thanks.

Errata

Even below freezing, albeit slower. This is the key principle: hygroscopic materials change their moisture content according to the relative humidity on each side and the driving forces, including vapor pressure and heat flux.

Cold sheathing is not risky, since neither mold nor decay organisms can grow in the cold. And, if sheathing has to wait until the warm summer months to begin to dry, then it's likely vulnerable to mold, if not decay, as soon as it warms up. Sheathing in a cold climate should be able to dry out continuously to the outside through permeable claddings.

If the sheathing is separated from the outside air by clapboards or some other thin cladding, its temperature will closely track the outdoor temperature regardless of how much insulation is behind it (unless there is little to none or its entirely air permeable and vulnerable to convective currents).

As Straube points out, dense-pack cellulose dramatically lowers the risk to sheathing, mostly because of it's high moisture storage capacity and its high moisture diffusivity, which quickly redistributes moisture to reduce local concentrations.

And because today's cellulose contains a very effective fungicide which is non-toxic to humans and pets, and which also repels both the insects and rodents which tend to create air channels in insulation.

Since the primary wintertime drying potential comes from heat flux through the sheathing, adding impermeable exterior insulation reduces both the heat flux and the vapor flux in the dominant wintertime direction.

Thick foam will further reduce outward (or inward) heat flux as well as vapor flow and thereby reduce drying potential in both winter and summer seasons.

An exterior ventilated gap will aid in drying of the outer surface of the sheathing, which is more likely to be wetted by exterior rain or humidity, but it also brings the sheathing into more direct contact with cold, damp outside air (winter air in most of the US has higher RH than summer air). A vented gap will also reduce inward heat flux and summer drying potential.

Moisture flow and its consequences can no more be stopped than the US Army Corps of Engineers can dam up a river and prevent flooding. The dam (or exterior foam) may prevent routine seasonal flooding (or moisture damage) but is more than likely to eventually result in catastrophic flooding (or moisture damage).

Since we cannot fool Mother Nature nor push a river, we would be wise to design and build houses to cooperate with nature's forces. This means structural and thermal envelopes that are reasonably air-tight, insulated with dense hygrosocopic moisture-buffering material (like cellulose), and breatheable in both directions but most importantly to the outside in a cold climate. A good rule of thumb is to keep the outer skin at least five times as permeable as the inside skin.

Such a structure, built with moisture tolerant materials, like sawn lumber rather than either plywood or OSB, will be a durable and healthy structure (assuming proper flashing and rain shedding details). Then extra complexities, such as rainscreen gaps, are not necessary (except with reservoir claddings such as stucco or masonry).

Is my wall ok ?

In the article, "Calculating the minimum thickness of rigid foam sheathing", one paragraph states,

"What if I live in one of the warmer climate zones?

If you are building a house in one of the warmer climate zones — zone 1, 2, 3, or 4 (except for 4 Marine) — you don't have to worry about the thickness of your foam. Any foam thickness will work, because your sheathing will never get cold enough for “condensation” (moisture accumulation) to be a problem."

Would that "any foam thickness" also include no foam at all ?

I am at the point of needing to install my windows and then put on the vinyl siding, and I'm not sure if I can get by without using any foam over the sheathing (don't want to foam it if I don't really need to).

I am in zone 3 (mid-western Arkansas) and my walls currently are 2x6 with 1/2" Zip wall panels which are OSB coated with whatever that water repellent coating is that Huber puts on the panels; the panel seams are taped with the Zip tape. I didn't plan to use a housewrap because Huber says that the Zip panels after being taped make a sufficient air barrier. They also said that a layer of building felt over the sheathing was not necessary because of the coating on the panels.

Question 1:

Do the above two statements seem logical ?

I will be using Roxul 5.5" bats between the studs and 5/8" drywall on the inside with latex paint.

Question 2:

For my climate, can I get by with no foam without risking condensation on the inside of the sheathing ?

(The Roxul is supposed to hold and release moisture better than fiberglass, if that makes a difference.)

(The house will be heated with a wood stove, if that makes any difference either. I know wood stoves generally make for dryer inside air than central heat.)

Response to Jim Wright

Jim,

Q. "Would that [statement that] 'any foam thickness' [will be safe in a warm climate] also include no foam at all ?"

A. Yes. You don't have to worry about moisture accumulation in OSB during the winter in Arkansas. However, a wall without any foam sheathing will not perform as well as a wall with foam sheathing (even in Arkansas), because of thermal bridging through your studs. To put it simply, a 2x6 wall without foam sheathing isn't as well insulated as a 2x6 wall with foam sheathing.

Q. "Do the above two statements [about the Huber Zip system] seem logical ?"

A. Yes, the Huber Zip system creates an effective air barrier (although you still have to worry about air leakage at the bottom and top edges of your wall, as well as air leakage through your floor system and ceiling). And yes, Huber has demonstrated that you can skip the installation of housewrap if you want. (However, conservative builders worry about the longevity of the Zip system tape, and often install housewrap as cheap insurance, in case the tape gives out in 30 years.)

Q. "For my climate, can I get by with no foam without risking condensation on the inside of the sheathing?"

A. Yes.

Will OSB dry to the outside?

I am building in Nova Scotia and have sheathed my house with osb. The exterior has been covered with house wrap and sided with vinyl siding ( but not strapped ). Now I am in the process of installing my 6' fibreglass batts in the 2x6 walls which I will then cover with 1" high density foil faced foam as my vapour barrier under my gyproc. My problem is, because it's winter here now, the inside of my sheathing and wall cavities are getting wet from the condensation of all the moisture within which freezes once it touches the osb. I've has some heat on from a wood stove I've installed, but that seems to make it worse. My question/concern is; once I install the batts and cover with my foam and seal all the interior joints, will the osb sheathing dry to the outside atmosphere? The builders gapped some of the osb sheathing, but not all. Should I drill holes within the wall cavities to the outside to assist in drying? I'm not sure how I could do that from within without breaking my house wrap.

Response to Doug Pulsifer

Doug,

Before I address your questions, here is some advice to GBA readers: don't do what Doug did. Remember, rigid foam belongs on the outside of the wall, where it can help keep the OSB warm and dry, not on the inside of the wall.

Don't worry, Doug, everything will probably be OK.

Ideally, you will wait until spring to install your insulation, so that the OSB can warm up and the walls can dry out. If that's not possible, crank up your wood stove, and at least wait for a warm, sunny day to get the OSB as warm and dry was you can before you enclose it.

Once your walls are insulated, you need to pay meticulous attention to air sealing to be sure that more interior moisture doesn't migrate into your wall cavities. That means using airtight electrical boxes (your electrician installed those, I hope -- the ones with flanges) and sealing the drywall or the rigid foam at the top plates and bottom plates with gaskets or caulk.

More information on the Airtight Drywall Approach can be found here:

http://www.finehomebuilding.com/how-to/departments/energy-smart-details/airtight-drywall.aspx?ac=fp

If you follow this advice, your OSB will dry to the exterior next summer.

Blown fiberglass

In all these articles I've read, the talk is to change from Fiberglas to blown cellulose. I assume you mean fiberglass batts. We have been using blown fiberglass , BIB, blown in blanket . It won't settle like cellulose, but it doesn't have the sorptive factor either .

What are your thoughts on blown fiberglass vs blown cellulose?

i build in the high desert of Central Oregon. Zone five . High, dry and cold. The best , affordable solution I've developed from research for this cold climate construction is; Air Drywall application , air barrier at the dry wall to keep conditioned air out of the wall cavity. ACH 1-11/2,50Psc. Double wall 7 1/2" BIB fiberglass wall. Ply wood wall sheeting. And using a vented air gap with reservoir sidings. We dont get much rain here, 10"/annual, so my concern with outside moisture is from solar driven moisture. I think the Hardie lap will provide an air gap with the laps eliminating the need for a vented air gap. I think if I'm incorporating a well vented attic, I can get by with OSB roof sheeting. Any suggestions ?

Response to Michael Scannell

Michael,

Blown-in fiberglass isn't quite as good as dense-packed cellulose at reducing air leakage, and it is less able to provide a hygric buffer to lessen the impacts of moisture changes in the wall assembly.

In spite of those two disadvantages compared to cellulose, blown-in fiberglass can work well.

You asked, "Any suggestions?" That's a pretty wide-open question.

Your wall has an R-value of about R-27 or R-28. That's pretty good, but some builders are aiming higher. Other than that, your wall sounds fine.

Insulation options overwhelming

Martin,

I have been a framing contractor for 19 years and now I am able to build my own home.

I am paying attention to all the options and ROI out there. I am almost to the point that the old ways are best, such as plywood not Zip or OSB and felt paper not synthetic for breath ability.

I am framing with traditional techniques because I like the strength of a good framed building, just not into the new sparce spaced framing right now.

My question to you is with insulation, I am putting in a geothermal system ,so am I crazy to just put in fiberglass batts in 2x6 walls and then spray foam the roof so to not run into any moisture issues. Also would I not need to vent the roof and everything under would be conditioned space?

I don't want the thick foam outside for the flashing and deep well details. Allowing the sheathing to dry out still seems best. Also flash and batt is risky because of human error.

Any opinion advice would be much appreciated

Thanks Keith

Response to Keith Miller

Keith,

1. If you install spray foam on the underside of your roof sheathing, it's clear that your roof assembly won't be ventilated. However, there are plenty of ways to build a ventilated roof if you prefer to have it ventilated. For more information on this topic, see How to Build an Insulated Cathedral Ceiling.

2. You asked, "I am putting in a geothermal system, so am I crazy to just put in fiberglass batts in 2x6 walls?" The answer is probably, "Yes." You didn't mention where you live, but that sounds like a lousy wall. In most parts of the country, a ground-source heat pump system costs $18,000 to $30,000. Why spend so much money on your heating and cooling system if you aren't even willing to invest in a high-R wall? There are plenty of ways to build a high-R wall that will avoid moisture problems.

Follow up to Martin

I am in zone 5, so I know the fiberglass batts are lousy, what is a good option without any moisture issues . With staying inside a 2x6 cavity without spray foam?

I am thinking only option is closed cell spray foam in the walls and roof, bite the bullet and get the cost savings over the long haul.

Or option 2 possibly the flash and batt with closed cell but after all I've read that seems risky with getting the right thickness

of foam

Your thoughts?

Thanks Keith

Response to Keith Miller

Keith,

Q. "What is a good option without any moisture issues, staying inside a 2x6 cavity, without spray foam?"

A. C'mon, Keith -- that's not fair. You're asking for a unicorn. Insulation between the studs doesn't make much sense. The best location for insulation is outside the studs, on the exterior side of the wall sheathing.

reply to keith miller and osb thoughts

As an diy'er and rental owner I also have an interested in doing things right/better. I saw (TOH) newer ways to insulate walls which was to spray the inside wall cavities with a latex sealer (to address convection) and finish the bay with regular glass batts. The intent that it should be less costly than a full spray foam fill.

I took real interest in seeing a room addition method in a rather low income neighborhood being executed. The roofers painted the osb roof sheathing seams with asphalt lap cement before applying the tar paper and shingles. Amazingly, they were addressing the tendency for the cut (and non cut) edges prone to absorb moisture and it was a practice I never saw being done in the multi million dollar home nearby neighborhoods! So maybe just like asphalt lap cement is used to waterproof cmu block walls, maybe that or even gloss latex paint might be used to waterproof the exterior walls - yeah not very economical or practical though.

I am still amazed at the building products that don't stand the test of time: compressed wood siding, aluminum wiring, cpvc water supply, pex fittings that leak with hard water, vermiculite insulation, lead paint, clay sewer pipe that lets roots in at the rubber gasket or won't take water jetting, steel drain pipe rusts through at the thinner threaded sections, steel water pipe that constricts (also used in the earliest radiant floor systems), and here's one you probably didn't know: abs drain pipe that rats chew through. In a vacancy, sewer rats chewed through the "Y" conjunction to build a nest in the walls - a rare downside, but obviously wouldn't have happened in steel or cast iron systems.

Alternative to the double stud wall

I'm curious how this issue would apply to an alternative wall assembly that I first discovered from builder Chris Corson who builds a basic 2x4 structural wall with OSB wall sheathing (taped on the outside to form an air barrier) then hang deep I-Joists on the outside of this. The outer edge of these I-Joists is wrapped in a vapor open and air tight material like house wrap or a ProClima membrane and then filled with dense packed cellulose. The 2x4 wall is also insulated but this assembly seems to completely eliminate any risk of cold OSB sheathing as there is no sheathing on the outside. The OSB structural sheathing is placed closer to the inside and should stay nice and warm, with drying paths in or out.

Am I right in thinking that this wall system is much safer than the traditional double stud wall?

Response to Mark Fredericks

Mark,

Q. "Am I right in thinking that this wall system is much safer than the traditional double stud wall?"

A. Theoretically, the answer to your question is yes. However, there may be practical issues with these walls that we won't know about until we have more experience with their long-term performance. For more information about the type of wall you describe, see The Klingenberg Wall.

Exterior Insulation

I live in Zone 6 ( dry ) in the Rockies. My builder wants to build the walls with 2x8 plates and staggered 2x4 studs. On the exterior we want to put rock wool sheets ( Roxul ) instead of foam. Of course we will have a WRB on the OSB. Would this be a better drying to the exterior option? Also how thick should the sheets be? Are the rock wool batts a good option for wall cavity insulation or should we use blown cellulose? On the interior would poly work or is vapour- permeable to the interior necessary?

Kevin

From Roxul's own literature available on their website the ComfortBoard IS w/a rain screen would be fine. Their website has ComforBoard IS going up to R12 (3" thick) and proposes a variety of wall solutions.

I don't know if it would be "better" than multiple layers of foam board with staggered and taped seams..

walls : 2x6 with roxul and 2" zip

Planning a new house and wondering about walls. The roxul is rated at r 22 and the 2" zip board with 1.5 " foam at r 9.6 ; this article and others seem to talk about the foam on the outside but the zip boards have the osb outside so.. is this a bad combination ; will interior humidity get through the drywall, roxul and foam zip to rot the foam osb ?

Response to Eugene Hunter

Eugene,

If you're using Zip-R sheathing -- which is OSB glued to polyiso foam -- you don't really have to worry about the OSB rotting. You have to worry that condensation will form on the inner surface of the sheathing, which in this case consists of polyiso.

If the R-value of the sheathing is too low, you'll get condensation on the polyiso (which faces the stud cavity), and the water will dribble down to the bottom plate and rot the bottom plate.

In short, the usual rules apply: the R-value of the Zip-R sheathing must meet the minimum R-value requirements shown in these two articles:

Calculating the Minimum Thickness of Rigid Foam Sheathing

Combining Exterior Rigid Foam With Fluffy Insulation

In your case, the total R-value of your insulation layers is R-31.6, and the Zip-R sheathing represents 31% of the total R-value of your wall assembly. That approach will work in Climate Zone 5 or anywhere warmer.

If you live in Climate Zone 6, 7, or 8, the R-value of the Zip-R layer isn't enough to keep your wall out of trouble.

Log in or become a member to post a comment.

Sign up Log in