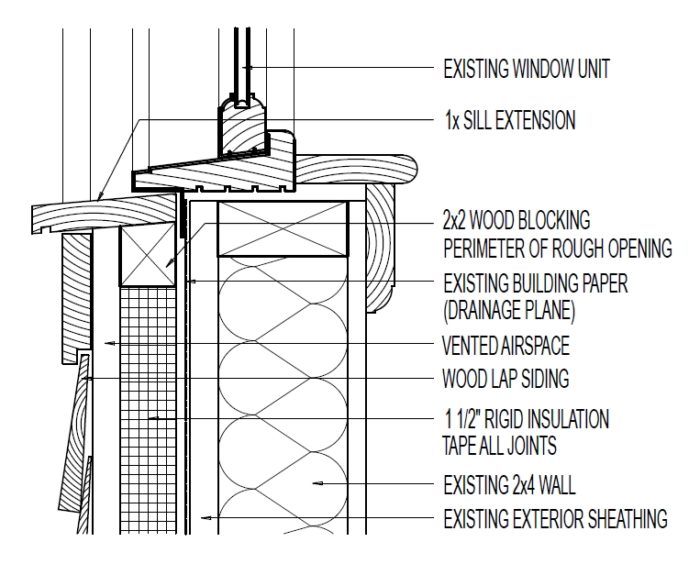

Image Credit: GreenBuildingAdvisor

Let’s say you’re building a house with plywood or OSB sheathing. You plan to install 2 or 4 inches of rigid foam on the exterior of the wall sheathing, followed by vertical rainscreen strapping and siding. Where does the housewrap go?

Depending on who you talk to, you get two different answers:

- It goes between the rigid foam and the vertical strapping, or

- It goes between the sheathing and the rigid foam.

I’ve heard a variety of arguments in favor of each position. For example, I’ve heard that the housewrap belongs between the foam and the strapping, “because that way it’s easier to integrate with the flashing at the logical drainage plane.”

On the other hand, I’ve heard that the housewrap belongs between the sheathing and the foam, “because that way it protects the sheathing,” or “to prevent the housewrap from flapping in the wind,” or even “to protect the housewrap from extreme temperatures which might degrade the plastic.”

Both sides of this argument have merit. If you have a strong opinion favoring either position, it’s safe to say that either approach can work well, as long as the housewrap is properly integrated with all of the window flashing, door flashing, and the flashings protecting other penetrations.

Simplifying the decision

If this quandary has you discombobulated, though, here’s an easy way through the thicket:

If you’re unfamiliar with the innie/outie terminology, an innie window’s flanges are in the same plane as the OSB or plywood wall sheathing, while an outie window’s flanges are in the same plane as the back of the siding. (For more on this topic,…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

47 Comments

polyiso

It's difficult for me to distinguish EPS and XPS. Both are fairly dense and appear to not sponge up liquid water. Polyiso on the other hand appears more fragile and porous.

Have you heard any concerns with locating polyiso outboard the WRB or are all the rigid foam products considered identical in this regard?

Response to J Chesnut

J,

If polyiso makes you nervous, there's nothing wrong with installing EPS on the outside of your wall sheathing. (I did that on my own house.)

However, I don't think your worries are justified. Commercial roofers have decades of experience using polyiso, which holds up well on roofs. If polyiso is installed on a wall under a rainscreen, it's hard to imagine how it could accumulate moisture.

Stucco

Martin, what are your thoughts about where the WRB should be located in an application with stucco. Wall>sheathing>foam board>lath>3 coat stucco. I know you advocate an air space between stucco and foam, but assume there isn't one.

Allan

Response to Allan

Allan,

I stand by the recommendation I made in my earlier blog, To Install Stucco Right, Include an Air Gap:

"If you’re installing stucco over foam, here’s how to create a ventilated rainscreen gap:

* Install 1x3 or 1x4 vertical strapping on top of the foam, screwed through the foam into the studs.

* Fasten paper-backed metal lath to the strapping, and proceed with a standard installation of three-coat stucco."

If you want further protection, there's nothing wrong with including a WRB between the foam and the vertical strapping.

Air Gap for Stucco

Martin, I agree with you that it is obvious that an air gap between stucco and sheathing or foam makes sense. However, I would guess the % of homes with that detail is .00001%. That doesn't make it right or wrong, but the conventional method of not using an air gap seems to be working. Almost all problems with stucco are due to poor flashing, inadequate WRB, poor mixes of the stucco, or not painting properly with elastomeric paint.

Another problem is code requires fasteners to be 6" on center, so vertical stripping would be problematic.

If I had unlimited money I would use 3/4" or even 1-1/*8 plywood sheathing, foam, vertical 1x4's (treated #1 SYP), with 1x4 fastening into plywood. I would also creat a brickledge to accommodate the sheathing, foam, stripping, and stucco.

Allan

Response to Allan

Allan,

In some parts of the country, it's possible that few stucco homes have wet-wall problems. But in other parts of the country, the failure rates have been very high. As I wrote in the earlier blog, "According to Ron Glubka, the chief building official in Woodbury, Minnesota, the city’s wet walls represent ‘the largest construction defect problem in local history.’ … Glubka [reports that] the building department has issued permits for wall repair work for 344 out of the 670 stucco-clad homes built in Woodbury in the 1990s — a failure rate of 51%."

After extensive interviews with building scientists and stucco experts, I concluded that these problems have multiple causes. You have listed some of the possible causes in your last post. I would also add several more, including the use of OSB, the use of interior polyethylene, high indoor humidity, and inadequate clearance between the bottom of the stucco and grade.

Every contractor needs to decide (in consultation with an insurance company) what level of risk to live with. If you want to install stucco without an air gap, it's a risk that you are apparently comfortable with. I wouldn't do it.

General Response

What about permeability? It is important to know the permeability of the foam being used, and whether or not to include an interior vapor barrier. The dewpoint within the wall becomes as important as when installing 'flash and batt', especially with foil polyiso (0 perms). To me, this is the real question to ask.

(But thanks for the discussion anyhow, I just asked J H on facebook and was referred to the following link: http://www.jameshardie.com/pdf/USTB_Increased-Thermal-Performance-with-James-Hardie-2.pdf )

Response to Sam Marsico

Sam,

Q. "What about permeability?"

A. The permeability of the foam or the housewrap doesn't matter much, because such walls are designed to dry to the interior, not the exterior.

Q. "It is important to know the permeability of the foam being used."

A. I disagree. When installed at a thickness of 2 to 4 inches, most rigid foams are low permeance anyway.

Q. "It is important to know whether or not to include an interior vapor barrier."

A. You are right about that. You do not want an interior vapor barrier.

Q. "The dew point within the wall becomes as important as when installing 'flash and batt', especially with foil polyiso (0 perms)."

A. No, it is not necessary to perform a dew-point calculation, whether or not you use foil-faced polyiso. All you have to do is be sure that the foam is installed with the minimum R-value required for your climate and wall thickness. To learn more, see these two articles:

Calculating the Minimum Thickness of Rigid Foam Sheathing

Are Dew-Point Calculations Really Necessary?

Air Gaps & Stucco

Martin, I am just not convinced an air gap is necessary when using stucco, especially as you propose (furring strips). For one thing, how do you get around the nailing pattern requirement for lath (6”OC). I really think it is an overkill solution that is expensive and adds a design detail that has to be addressed: the added thickness of the furring strips in relation to foundation, windows, and doors. With sheathing, foam, furring strips, and stucco you could be talking about 3” of material past the frame. I would not want that much hanging out past the frame, you almost need a brick ledge like detail, and of course allow for this in your design.

Now if you advocated drainage mattes, I might agree. I also would not use a city in Minnesota as my sample data, I just don’t think of northern cold climates areas as hot beds for stucco use. It would be like using Houston as a test area for basement construction, we just don’t do enough to be proficient with them. If they are having 50% failure rate, they just don’t know what they’re doing in regards to stucco and flashing. Don't get me wrong, there are a lot of bad stucco (and mostly flashing) jobs out there, I just don't think adding furring strips is the solution. Although I will admit it is a bit idiot proof.

For years my stucco contractor has talked about using a “rich mix” in regards to stucco, I found this article interesting. http://www.coastalcontractor.net/article/94.html I think this is another factor, the mix of the stucco. Also, as an extra precaution, I have always used 3 layers of WRB, and pay close attention to flashing detail. And of course I use nothing but copper flashing, I would never use galvanized. I also keep the stucco of the roof 3”-4” on rake walls, and as you mentioned keep the stucco minimum 6” above grade.

Another thing I’ve noticed is that I have never seen water or signs of water draining via the weep screeds. We build on foundations and you would think that there would be some kind of water staining after years of water weeping down thru stucco. Makes me wonder how much water really gets thru stucco.

Allan

Response to Allan

Allan,

I have never installed stucco, so I'm happy to defer to the stucco experts when it comes to attachment details. If any GBA readers want to share their preferred methods for attaching wire-backed lath to a foam-sheathed wall, ideally with an air gap behind the stucco, please share them. What's the maximum thickness of foam you have ever installed?

As I wrote before, Allan, you seem to have found a stucco installation method that works for you, at a level of risk that you feel comfortable with. I'm not trying to convince you to change your techniques.

A few more comments:

1. Integrating thick foam sheathing with stucco is difficult, especially if you want an air gap between the stucco and the foam. Anyone who insists on stucco cladding might prefer a wall construction method that doesn't require exterior foam -- for example, a double-stud wall or a wall with interior horizontal strapping to address thermal bridging.

2. It's up to you to decide: what's more important, the air gap or the foam?

3. Not every house needs stucco! Unless it's installed directly onto concrete blocks, mortared stone, or poured concrete -- the way it was originally installed in Europe -- it's a relatively risky siding.

4. You could always consider water-managed EIFS.

More Stucco

I don’t want to beat this to death, I think your blogs on stucco and WRB placement are very well written and good advice. It’s just that over the years I’ve heard some negative things about stucco (Atlanta in particular had a lot of problems). Since I started using stucco in the mid-late 80’s, maybe built 75-100 homes with stucco, I’ve had less callbacks, warranty, and problems with stucco than any other aspect of construction. In fact, amazingly I don’t remember any callbacks on stucco.

By the way, EIFS has a terrible reputation and not even sure it is allowed on residential.

In my climate (hot and humid), I really like the idea of foam board (even ¾”-1”) on the exterior. One difficult thing regarding double walls and the such, I feel I have to work within the confines of what local architects design and “traditional” building methods. It is very difficult to implement methods too much out of the mainstream, smaller incremental changes are a bit easier.

Allan

Martin,

If you follow the

Martin,

If you follow the link in my first post, scroll down to the table and read 'special considerations'. JH is recommending interior vapor barriers with foam sheathing in cold climates. What is your opinion?

I see your point about not needing to do dp analysis if you install at least the minimum foam thickness for the respective climates, but I'm still cautious about relying on drying to the interior. Osmosis occurs from high to low concentrations, so wont vapor always drive toward the exterior during a cold dry winter?

About Stucco:

I recently used Benjamin Obdyke homeslicker behind a stucco installation. I installed an air barrier, then the homeslicker, and had the subcontractor install 60lb jumbo tex with cap nails, so the stapler wouldn't rip the paper as the Obdyke product compressed. My stucco sub absolutely refused to use paper backed lath, claiming it is for bottom feeders.

Thanks for the links.

Response to Sam Marsico

Sam,

You wrote, "James Hardie is recommending interior vapor barriers with foam sheathing in cold climates."

No -- read it more carefully. They are recommending vapor retarders, not vapor barriers. The best vapor retarder for these applications would be vapor-retarder paint.

Q. "Won't vapor always drive toward the exterior during a cold dry winter?"

A. Yes, that will be the direction of the vapor drive. But not much vapor can drive through rigid foam. Moreover, if the entire wall assembly is warm, what harm is there? There aren't any cold surfaces that allow condensation or moisture accumulation.

The conditions in your wall will be closer to the indoor conditions in your living room than they would be in a house without foam sheathing.

Thanks,

I didn't realize

Thanks,

I didn't realize there was a difference.

Off topic, but today I was wondering why the snow was deeper where all the rafters were ghosting through on a comp roof. It seems to contradict what I thought I knew about thermal bridging. Do you have anything about this phenomenon in your blog?

Rafter ghosting

Sam,

The ghosting patterns on snow-covered roofs are always revealing. Different roofs show different melt patterns.

It's certainly possible for the rafters of a roof to be the most insulated part of the roof assembly. I have often seen the pattern you are describing -- a roof where each rafter shows a stripe of deep snow, but the snow between the rafters is melting.

What that means is the rafter is the best insulated part of the roof assembly. This is typically the case in an uninsulated roof over an unconditioned attic, a garage, or an outbuilding. If a little bit of heat is leaking from the building below, or if solar gain through windows has heated up the interior of an outbuilding, then snow will melt between the rafters. The rafters (being 9 inches of solid wood) have a higher R-value than the roof sheathing (which is often only 1/2 inch of plywood).

A comment from Kohta Ueno

[Kohta Ueno sent me the following comment by e-mail]

I have attached a shot of an installation of stucco over furring strips from BSC/Gauvin Construction's Coquitlam Vancouver test hut.

A 3/4" air space is a code requirement in Vancouver, so this installation of stucco is pretty much their standard solution now. They use a product called Hal-Tex Rainscreen Breatherboard.

However, I don't think that the installation here was over foam--I believe it was structural sheathing, building paper, 3/4" ventilated airspace, and BreatherBoard. Some of the folks who are closer to the experiment, like Joe Lstiburek, John Straube, or Chris Schumacher, would be able to confirm that.

But there's no physical reason why you couldn't do it over foam with furring strips; there's a boatload of compressive strength available.

Kohta

Santa Fe Stucco

Typical frame, rigid insulation, and stucco details here in Santa Fe, which is quickly becoming virtually everything built here, is rigid installed directly on full OSB sheathing with minimal usage of spiral capped nails. Then double layer jumbo-tex, again with minimal nails, (some even use short roofing nails just to hold the paper in place on the foam) then the stucco netting with a whole lot of spiral-capped nails to hold the entire, foam,paper, wire assembly firmly in place. The theory of the double paper is that the wet, three-coat cementious stucco wrinkles the exterior layer of paper enough to create drainage channels between the two layers of paper so that moisture that may get into the stucco by wind-driven moisture and and then travels along all the spiral nails won't make it to the OSB. Interior moisture is not presumed to get to the backside of the OSB because of the use of blown-in cellulose or fiberglass with no interior vapor barriers.

Our challenge is that our "innie" windows are REALLY "innie" with no jamb extensions because we like the look of deeply recessed windows with big rounded bullnoses on all four sides. Often we install an extra 2x4 "buck" inside a 2x6 rough opening to enhance the recess. Some of our fancier neighborhoods even have covenants that require the plane of the window glass to be 4" deeper than the plane of the stucco! The idea is to mimic the look of a classic thick-walled adobe. Flashing is our greatest challenge, but we strive to get any moisture inadvertantly coming in through the window/stucco interface to exit between the jumbo tex and the stucco and then down to the weep screeds.

We recognize that we are a unique climate with unique design details and that our experience does not readily transfer to very many markets, but what I describe seems to be working very well here. We are a cold, dry climate with most of our ambient moisture occurring during our "monsoon" season of July and August.

Response to Kim Shanahan

Kim,

What's the thickest layer of foam that can be used with the assembly you describe?

How long are the spiral capped nails?

thickness

2" R-10 is the thickest and most typical. Even Habitat for Humanity does it here because they get free material from Dow. The spiral nails are typically 3" , which mean penetration through the 7/16 OSB and occasionally into the 2' O.C. studs. Most good lathers will make an effort to hit the studs and then also fill the field to get the netting to lay flat. Habitat also glues their 2" rigid with a gun-grade adhesive, which I have advised them is overkill, but it keeps the unskilled volunteers busy and keeps the rigid tight to the OSB until the stucco pros show-up, which can be days later.

Photo in Comment 16:

With furring strips as wide as they show, how do you attach lath and satisfy the 6" OC requirement for fasteners?

Response to Allan Edwards

Allan,

See this technical bulletin from HAL Industries on the product in question:

http://www.halind.com/assets/pdf/RBP500_Tech_Bltn_2009-04-13.pdf

See also the attached image, which reproduces the relevant paragraph:

Response to Martin

The document you referred to seems to be in conflict with the code spacing requirement as I understand it. We actually have a City inspection of lath (to verify spacing) and weep screeds before we can apply stucco. I will confirm.

It also recommends 1x2 furring strips 8: on center, I assume these run vertically. If your framing members are 16", 19.2", or 24" OC, that means the 1x2 only attach to sheathing. If your plate is 12' high, not sure I feel comfortable with that detail from a structural viewpoint.

Response to Chris

Chris,

First of all, several suppliers, including Maze Nails, makes cap nails up to 6 inches long. (Maze doesn't mention them on their website, but they do make them. Call Maze at 800-435-5949.)

Secondly, there are many ways to flash a window. If you want to be a student of the issue, you can order ASTM E2112, the industry's window installation standard: "Standard Practice for Installation of Exterior Windows, Doors and Skylights." It is 89 pages long.

Or you can follow the instructions provided by your window manufacturer.

Or you can watch an 8-part video series on the topic on the GBA website.

still confused

So I've got my 2 layers of foam installed and have the picture frames for the openings made. I'm ready to install my typar house wrap but I'm not sure the order of events. Should I install the the peel and stick flashing on the openings and then wrap the typar over it, or should I secure the house wrap in the jambs and head and just do the peel and stick flashing on the widow sills? Also how do I even secure the house wrap over so much foam, The typar website just recommends nails with plastic washers but those are all too short. I bought the nails anyway and intend to remove all the washers and use them with 3" galvanized drywall screws but it seem like there must be a better way. I used roofing tins and screws to secure the foam like my local building supply place recommended, but they're already rusting and I could see them eventually staining the vinyl siding, so I definitely want to go a different route on the house wrap. I can't seem to find this info anywhere on the site, please help. -Chris

foil housewrap?

I am planning the following wall system for my house (inside to outside):

wallboard => 2x6 studs w/R23 Roxul Comfortbatt => OSB => exterior foamboard (probably 3" of XPS) => housewrap => 1"x4" rainscreen strapping => hardie siding

While I have tried to go through most of the articles and comments on the subject here at GBA, I have not found anybody who has discussed the value of a foil layer facing the rainscreen air gap. It seems like this could add some value (especially in the summer) to the wall system. This could be accomplished in a couple of ways but 2 I can think of are by using foil faced foam as the last layer before the air gap, or use one of the foil products like Arma Foil, or RadiantGuard as the housewrap over the foam.

My questions are:

1. has anybody done this or have opinions on the value of foil facing the rainscreen air gap

2. if it sounds valuable, what solution would you use

3. is it possible this could actually be a useful application of foil housewrap products?

4. if using a foil based housewrap, would it be better to go with the perferated ones (with a permiability rating of 6.9 perms) or a vapor barrier version (rated at .006 perms)?

Thanks for your help.

- MikeB

Response to Mike B

Mike,

The main problem with using foil as a housewrap is that it is a wrong-side vapor barrier. In most walls, foil in this location would trap moisture that accumulates in the sheathing over the winter, and would prevent the wall from drying to the exterior.

Housewraps are designed to be vapor-permeable; foil is a vapor barrier.

The only way to do this safely is on a wall with an adequate thickness of exterior rigid foam. It sounds like you have figured this out. Walls with exterior foam are designed to dry to the interior, not the exterior -- but they only work if the rigid foam is thick enough to keep the sheathing above the dew point during the winter. For more information on these issues, see Calculating the Minimum Thickness of Rigid Foam Sheathing.

If you are installing thick foam on the exterior of your wall, then you've already prevented drying to the exterior -- so the foil layer does no additional harm. Most builders who want exterior foil simply use foil-faced polyisocyanurate. It's also possible to buy foil-faced EPS. In general, green builders avoid the use of XPS, because it is manufactured with a blowing agent with a high global warming potential.

When foil faces an air space as your propose, it raises the R-value of the air space from R-1 to R-2 or R-3, so you get a small boost in R-value from the foil. For more information on radiant barriers, see Radiant Barriers: A Solution in Search of a Problem.

In the wall you are planning to build, either an ordinary radiant barrier or a perforated radiant barrier will work. In general, I'm skeptical of the perm ratings provided by manufacturers of perforated radiant barriers. The materials probably don't allow as much drying as the perm ratings indicate, and perforated radiant barriers have the potential to trap moisture -- so I wouldn't use this product where a vapor-permeable layer is needed.

Thanks Martin

Thanks Martin, I appreciate your quick response.

Yes, I did the calculations for foam thickness in my area (6b by the map). I get a 3 month winter average temp around 24.5F according to some hand calculations with historical temps, and decided that R15 should be sufficient to avoid in-wall moisture conditions.

As you say, with that amount of foam on the outside, my assumption is the wall will be forced to dry to the inside, so if I decide to use foil wrap, I am hoping the foil shouldn't make that problem any worse than what the foam would already be doing.

Since I am planning to use some sort of house wrap on the outside of the foam anyway, using a foil product instead of Tyvek, etc. would give me an extra 1 or 2 R factor (due to radiant effects) with very little extra work or cost.

For what it's worth, I have not yet decided what kind of exterior insulation board I want to use and am debating with myself on a regular basis. Balancing R-factor, "green-ness", cost, fire resistance, and insect concerns creates a nice little storm in my head that I haven't found my way out of just yet. :-)

At any rate, thank you for your insights.

- MikeB

Shouldn't this be "Where does the WRB go?"

I wouldn't think that this article is specific to housewrap and not to WRB's in general, but the wording suggests that it is. The title is, "Where does the HOUSEWRAP go?", and the subheads also specifically refer to housewrap rather than WRB's. Is this article (or parts of it) indeed specific to housewrap, or does everything here apply equally to asphalt felt paper?

Response to Michael Bluejay

Michael,

I was definitely thinking about housewrap when I wrote this article. (And by the way, from a journalistic perspective, "Where Does the Housewrap Go?" works way better as a headline than "Where does the WRB go?")

Every WRB is different. For example, you wouldn't want to try to install a liquid-applied WRB over rigid foam (unless, of course, the manufacturer of the liquid-applied WRB specifically recommended that application).

Asphalt felt is very awkward to apply over rigid foam, for a variety of reasons, and few people use it in that location. It would be fine to install asphalt felt between your wall sheathing and rigid foam if you wanted to do that, however.

Purpose of housewrap under foam board

Can you tell me if the housewrap actually serves a purpose underneath foam board?

First post, I have been researching for about a year, read every article and link I was able to. Current project is crawl encapsulation and insulation. Replacing 3 exterior doors and 1 window (Innie). I had a quote to encaps from inside, but after researching I like the idea of exterior insulation. I have since set aside a healthy budget and am trying to do this in best practice. I'm excavating to footer, clean stone and french drain, Carlisle 860 peel and stick up to and past rim joist 24" onto house, 2 layers of 2" of EPS staggered seams, a protective barrier 12" below grade and 4" above, firing strips and corrugated metal or stone veneer for aesthetics. This was an effort to ensure the sill and rim joist was air sealed. In a year or so when I do siding and the rest of the windows I will add the rest of the 4" of foam up the wall. My original thought was the peel and stick up the walls and on roof, but in reality this may be a little too lofty for my goals and time staying in house. Plus it's a 12/12 or 14/12 and the roofers I asked weren't keen on 8" of foam. So this brings me to my house wrap question, and it's pertinent now, because I am replacing doors and a window and flashing correctly. So if the housewrap serves a purpose under foam, I will do it on the wall that will be exposed. I just don't understand the function. I originally thought you wanted a foam wall completely air sealed under foam, but in further research, that doesn't seem to be critical, just R requirement for zone 5 (R-5 walls). Tyvek recommends their drainage wrap, to break capillary action if water does get under foam, I just am not sure it would perform. House wrap I think would allow me to ignore the roof for the time being, without causing sealing issues, correct?

Regular house wrap can't act as a drainage plane if there isn't a gap and a gap negates the foam insulative properties; to my knowledge and is vapor permeable, but even EPS foam in 4" will negate drying to the outside. So is the housewrap at that point not just a waste? What purpose does it serve?

The purpose of housewrap under the foam board...

The purpose of housewrap under the foam board is to provide a drain plane for managing bulk water being directed to that layer by the window flashing. This is sometimes referred to is "innie" mounted windows. If the windows are pushed a bit out to further to the exterior with the flashing directing water to the exterior of the foam, the housewrap goes on the exterior side of the foam. (If the foam is detailed as a weather resistant barrier the housewrap may be omitted in "outie" window mounts.)

The crinkly housewrap provides a reasonable drain space, and measurably better drying capacity for the sheathing, while taking a very miniscule (hard to measure, really) hit in thermal performance. Not a lot of air can move through the crinkle channels, but it doesn't need a lot of space for gravity to do it's business with the bulk water, and air to finish the rest.

Drainage plane daylighting on roof headwall

I'm doing an exterior foam retrofit on walls that will lie above a standing seam metal roof. An "innie" design will be used for windows so I understand its best to use the wall's original drainage plane as the final one. I'm having trouble though visualizing how the drainage plane lying behind the exterior added foam is daylighted at the bottom of the wall and integrated with the roof flashing. I've searched construction details and discussion but have not found anything related. Could you please direct me to content or advise? Thanks.

Response to Andy Alden

Alden,

The type of wall you describe will need some type of flashing at the base of the wall -- flashing to address the interface between the bottom of the wall and the roofing below the wall. Your WRB should lap over the top of this base flashing.

If the rigid foam is exterior to your WRB, the rigid foam and siding will create a thick layer of wall components exterior to the flashing at the base of the wall, so the base flashing will be in a type of cave at the base of the wall. This works, especially if the cave is at least 4 inches high, but it may be aesthetically unsatisfying. The solution would be to move your wall's WRB to a new location (on the exterior side of the rigid foam).

One final point: It's almost impossible to get a significant amount of liquid water draining off the WRB in a wall like the one you describe, so you may feel confident in breaking the usual flashing rules. However, do so with your eyes open, and at your own risk.

I have yet to fine detailed information on best practices in how to configure housewrap and flashing tape elements where it involves the use of extended wooden bucks and outie flanged windows. I'm specifically after details in which mineral fiber is being used, and the wrap is behind the insulation on the sheathing. How does one bring the WRB around these projections of the buck and flash them ? If you then picture-frame the buck with 3/4" x 4" furring stock (after installing insulation up to the buck) to produce a wide, flat surface for the window flanges to be nailed, the flashing of the window flange cannot be taped to the WRB because the wrap is now hidden by the flanges. Is caulking under the flange sufficient?

To bring the WRB to the plane of the flange further out from the window beyond the flanges, what are the best methods, if they are done routinely?

Or do installers of windows in projecting bucks prefer flangeless windows so that so they can directly tape the front window-frame gap, thus bridging the frame, buck face (with wrap), and picture-window furring ?

Regarding the statement: "All you have to do is come up with exterior “jamb extensions” — including a sloped secondary sill tucked under the sill that comes with the window — to cover the edges of the foam at the window and door openings,"

...can you point to videos or guides how to do this with cellular PVC for vinyl windows?

Are there any major window manufacturers that have such trim extensions as part of their vinyl product line? They all have interior extensions and various brick mold options, but deep brick mold options appear uncommon.

Richard,

See this article: "Deep-Set Brickmold Trim for ‘Innie’ Windows."

If installing the housewrap on the sheathing, would it be standard to seal the bottom ends of the foam to the housewrap to keep it air tight? Or would it be a better idea to leave the bottom unsealed for any potential water that would need to drain out from between the foam and sheathing?

Austin,

In most cases, the air barrier will be at the sheathing layer -- so you will tape the sheathing seams. I wouldn't install any caulk at the bottom of the rigid foam (between the rigid foam and the housewrap), although there won't be any problems if you do, since there isn't really any chance that liquid water will ever get past the rigid foam.

Martin

Have enjoyed reading your articles and advice for a while now and have subscribed to GBA Premium for myself and our carpenters to continue our learning journey.

We are located in Winnipeg, MB, Canada and I am a big fan of exterior foam insulation with 1/2 or 3/4" rainscreen detail (regardless of exterior finish product). We must be cognizant of our assemblies drying to the outside as our local building code absolutely mandates the use of a 6 mil poly vapour barrier inside. This is why we favour 1" EPS (Halo Exterra specifically) with a rainscreen to reduce the double vapour barrier effect.

In our case, what would you suggest as the best detail. Typically we'd also be installing the windows as "outties".

Thanks!

Oswald,

Q. "What would you suggest as the best detail?"

A. There are several issues here. One issue is the ratio of the exterior rigid foam to the total R-value of the wall. One inch of EPS is only about R-4, which isn't enough for your climate zone. For more information, see "Calculating the Minimum Thickness of Rigid Foam Sheathing."

Winnipeg is probably Climate Zone 7, so your continuous exterior insulation should have a minimum R-value of R-10 for 2x4 walls, or R-15 for 2x6 walls.

There are two possible solutions:

1. Instead of interior polyethylene, use a variable-permeance interior vapor retarder -- something like MemBrain -- if your local inspector will accept that option.

2. Use semi-rigid mineral wool instead of EPS as your layer of continuous exterior insulation layer. Mineral wool is vapor-permeable.

This is a complicated issue. One relevant article you might want to read is "Rethinking the Rules on Minimum Foam Thickness."

Martin: I've just recently read about every article I can find on GBA (and other sites), and the rigid foam thing in cold climates is throwing me for a mental loop. My understanding is that in cold climates (like zone 6 or colder), you want the house to dry outward. However, once you put on, say, 3" or more of rigid foam, aren't you now forcing the house to dry inward? Isn't there a battle of wills that occurs at the sheathing (assuming you have drywall, stud + batt, sheathing, membrane, foam, rainscreen).

It seems like the detail between using thick foam or something like semi-rigid mineral wool is identical in layout, but they behave completely opposite of one another in terms of drying. I'm having a hard time squaring this up in my head...

Kenmore,

Moisture accumulation in sheathing happens when the sheathing is cold in winter. That's when interior moisture, carried to the sheathing by the mechanism of moisture diffusion, can accumulate in the sheathing. The process is similar to condensation, but it's called sorption when it occurs in a porous material like wood, plywood, or OSB.

When you install an adequately thick continuous layer of insulation (either rigid foam or semi-rigid mineral wool) on the exterior side of the sheathing, the sheathing stays warm in winter, and so the moisture sorption never occurs. Warm sheathing is dry sheathing. Countless field studies (using moisture meters that monitor the moisture content of sheathing) have confirmed this.

Walls with a continuous layer of exterior insulation will stay dry, but they should be able to dry in at least one direction in case of moisture intrusion from rain. So you should never install interior polyethylene on a wall with exterior rigid foam. These walls should be able to dry inward.

All of this is explained in my article, "Calculating the Minimum Thickness of Rigid Foam Sheathing."

If you want to install "innie" doors and "outie" windows on a foam sheathed wall is it permissible to change the plane of the house wrap as wall features (doors/windows) change? For example, if you have a door on one end of a wall followed by a series of windows could you install the house wrap on the plywood/osb sheathing (around the door) and then move it to the outside of the foam by cutting it (so the foam layer can be continuously taped) and overlapping it for a couple of feet in preparation for the upcoming windows?

PVO,

What you suggest is possible, but it requires meticulous detailing at the complicated seams. I'm not sure it's the best approach. But if you can think through all the details, and lap all of your materials so that the laps shed water, it's possible to make it work.

If installing the WRB on top of the foam, do you need to use a selfadhering wrb? Or does it just get tacked to the foam for temporary holding and then the strapping will provide further support once installed?

Chris,

Attach the housewrap to the rigid foam temporarily. The strapping will provide further support.

You'll probably be needing long cap nails to fasten the rigid foam to the sheathing or studs, so just use a few of the same type of cap nail for attaching the housewrap.

Thanks!

Log in or become a member to post a comment.

Sign up Log in