Image Credit: Johns Manville

Colleen A, planning a new house in Michigan’s Climate Zone 5, has discovered there’s a downside to the wealth of insulation products on the market: It’s hard to make a decision.

“There are so many options on exterior insulation that my head is spinning,” she writes in a Q&A post at GBA. So far, her research has led her to an exterior wall assembly that includes a 2×4 framed structural wall filled with 3 inches of closed-cell polyurethane foam, oriented strand board sheathing, 1 1/2 inches of extruded polystyrene rigid foam, and Tyvek DrainWrap as a water-resistant barrier.

She’s considered other possibilities, including a 2×6 framed wall, Roxul mineral wool insulation, and polyisocyanurate rigid insulation. There are drawbacks to all of them.

And then there’s the issue of building industry inertia, the difficulty of finding local builders as interested in the topic as she is.

“We will be our own contractors for the house,” Colleen writes. “I haven’t found any local builders that specialize in energy efficiency. From anyone I’ve talked to so far not many are interested in doing above and beyond code and seem to think it’s a waste of time and money. I don’t think so.”

Colleen’s questions are the topic for this Q&A Spotlight.

Exterior insulation is the right idea

Colleen is on the right track with exterior insulation, writes GBA senior editor Martin Holladay, even if some of the details in her wall assembly are less than ideal.

“Installing a layer of rigid foam on the exterior side of a 2×6 wall is a good idea,” he says. “This will increase the R-value of the wall, reduce thermal bridging, and reduce air leakage.”

But, he adds, installing spray polyurethane foam in the stud cavities is not a great…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

22 Comments

Seems par for the course. I can only imagine the push

back if the OP spec'd the house with 2x6's on 24" center.

easy to narrow down

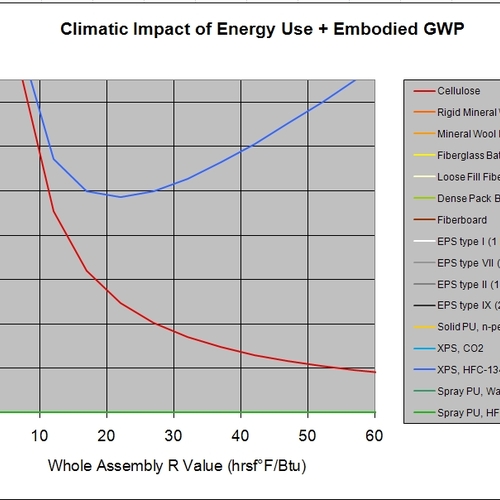

There are a variety of insulating materials, but as the article demonstrates, it is relatively easy to narrow down to one or a few based on cost and environmental impact. I find it hard to beat expanded polystyrene and mineral wool.

---

"In the stud cavities, cellulose, fiberglass, or open-cell foam are more environmentally friendly and cheaper," he adds. "Although they have lower R-values per inch than closed-cell foam, the impact on whole-wall equivalent R-value is pretty small because of the thermal bridging of the studs."

There are lots of options,but

There are lots of options,but when you know how they work, what the pros and cons are and the costs its not that hard to pin down what you need

That said you need to know more then the average person, you need to know their properties well.

John Clark

I guess it depends on local practice. Almost all houses here have been framed with 2"x6" @ 24" oc for decades. It is only recently, with more stringent seismic requirements, that 16" has become more common.

clarification

When Dana writes: "A 2x4 wall with 3 inches (R-20) of two-pound closed-cell foam has almost exactly the same thermal performance of a 2x4 wall with 3 1/2 inches (R-13) half-pound open-cell foam, despite the higher center-cavity R, due to the thermal bridging issues" does she mean open cell PLUS exterior rigid? If not, what about open cell helps with thermal bridging?

Many thanks.

-Isaac

Clarification 2

Dana is not a "she". Dana is the screen name of a team of building scientists who post here collectively.

But seriously:

https://www.greenbuildingadvisor.com/community/forum/general-questions/28198/who-dana-dorsett

Clarifications

DANA stands for Definitive ANAlysis.

Here's my not-definitive analysis of that comment. Once you fill a 2x4 stud will open cell foam, the open part is so well insulated that a large fraction of the heat leakage is through the studs, not through the foam. So improving the foam doesn't do much good. Neither foam does anything to solve the thermal bridging. That's why the net result is about the same.

More info on open-cell vs. closed-cell between the studs

Isaac,

Closed-cell spray foam is so dense that it is difficult to trim. That's why installers of closed-cell spray foam never fill a cavity completely. In a 2x4 wall, the installer will stop at about 3 inches instead of 3.5 inches, leaving the typical bumpy surface of foam. This type of installation doesn't need to be trimmed.

Open-cell spray foam is easy to trim. Installers of open-cell spray foam fill the 3.5-inch-deep cavity completely, allowing the foam to be proud of the studs. Once cured, it is trimmed flush with the studs.

With closed-cell spray foam, the exposed sides of the studs (the portions that extend inwards beyond the 3 inches of foam) make the thermal bridging penalty worse.

With open-cell spray foam, the sides of the studs are not exposed, lessening the thermal bridging penalty. Even though the open-cell spray foam has a lower R-value per inch, the thermal performance of the wall assembly is better than you might think, because the assembly benefits from the fact that you can completely fill the stud cavities.

-- Martin Holladay

Re: clarification (response to #5)

Martin's explanation is correct. With closed cell foam ~3" path through the R1.2/inch wood is about R3.6 for the ~25% framing fraction, whereas with a complete cavity fill the framing fraction is 3.5" deep, good for ~R4.2. The ~R0.6 difference may not seem like much when expressed as R value but the heat transfer is a funcition of 1/R

1/3.6= 0.28

1/4.2= 0.24

0.28/0.24= 1.17 x, or 17% more heat transfer through the framing fraction, which already has a disproportionately high heat transfer than the 75% of the wall area that has cavity insulation at ~4x the R-value of the wood ( or 1/4 the heat transfer per square foot) with 3.5" of open cell foam or ~5x the R value ( or 1/5 the heat transfer per square foot) with the 3" of closed cell foam. With the closed cell foam MOST of the heat transfer through the wall is through the framing fraction.

Put another way, when you factor-in the thermal bridging a 2x4/R13 wall with typical sheathing & siding options has roughly the same heat transfer rates as a continuous R10 insulation or a "whole-wall R" of R10.

A 2x4/R20 wall with 3" of closed cell foam with the same options comes in at about R11 whole-wall, about a 9% reduction in heat flow.

That makes the 3"/ R20 closed cell option a VERY expensive ~R1 compared to other ways of achieving the same whole-wall performance gain, eg: (an additional) 1/4" of continuous foam sheathing, which is an almost negligible cost adder- at most 10 cents per square foot. 3" of closed cell foam costs about $3 per square foot, 3.5" of open cell foam about $1.20 per square foot, so that additional R1 performance for going with closed cell costs about $1.80 per square foot, more than 15x the cost of fattening up a continuous foam layer.

clarification

Makes perfect sense Martin and DANA ;) ! I gotta say...the information on this site is amazing, so happy to have access to it.

I ask for clarification mainly because my because I am in the midst of a not-so-deep energy retrofit of an old farm house from the 1930s in Long island, and I am about to install 2" of closed cell foam in my 2x6 roof rafters, and the contractor gave me an attractive price to do the same on my exterior walls. My alternative is to use Roxul ComfortBatt at R-15 with a certainteed membrane on the interior side, which I will install myself. I asked the contractor (as well as the other company I got my backup quote from) about using open cell instead of closed on the exterior walls as I read about so often on this site, and both said they wouldn't do it. They seem to be die hard closed cell converts. Is that a bad sign?

-Isaac

PS: Can I put 1/4" continuos foam (i.e. OC fanfold) on the interior of a wall? Between the studs and drywall?

Response to Isaac Brest

Isaac,

Q. "I asked the contractor (as well as the other company I got my backup quote from) about using open cell instead of closed on the exterior walls as I read about so often on this site, and both said they wouldn't do it. They seem to be die hard closed cell converts. Is that a bad sign?"

A. I wouldn't call it a bad sign. Lots of contractors specialize in certain specific materials. But if you have decided to specify open-cell spray foam, you need to find a contractor who is willing to install it.

Q. "Can I put 1/4 inch continuous foam (i.e. OC fanfold) on the interior of a wall? Between the studs and drywall?"

A. Yes. For more information on this approach, see Walls With Interior Rigid Foam.

-- Martin Holladay

Exterior only? Double stud?

1. Given the superiority of continuous external insulation, why insulate the wall cavity at all? Could you just put enough exterior EPS or mineral wool on (even if you might have to build out a ledge for support), use furring strips and long screws (to secure and penetrate to studs) for the siding, and leave the interior cavity insulation-free? Would that be less expensive to do (one labor pass on one side of the wall rather than two)? Or does it violate fire code to have exterior, load bearing walls with open cavities, despite blocking?

2. Also, I've been enamored of mineral wool ever since hearing some Lstiburek talks on insulation/wall assemblies; is it competitive in cost with EPS, as exterior "boards?"

3. If we're talking about insulating a wall cavity, and the complicating factor is thermal bridging, why not consider a double stud wall? 2x4s 24" OC staggered, should be stronger than 2x6, too. Is it significantly more expensive, or hard to find contractors who can do it?

4. On wall cavity insulation, I've seen dense packed cellulose held in by some sort of clear plastic sheeting (for inspection, before the drywall goes up). Doesn't that prevent the "dry-to-the-inside" capability that is supposed to be more attractive for cellulose?

Response to Stuart Miller

Stuart,

Q. "Could you just put enough exterior EPS or mineral wool on (even if you might have to build out a ledge for support), use furring strips and long screws (to secure and penetrate to studs) for the siding, and leave the interior cavity insulation-free?"

A. Yes. That approach is called PERSIST. For more on the PERSIST approach, see Getting Insulation Out of Your Walls and Ceilings.

Q. "Would that be less expensive to do (one labor pass on one side of the wall rather than two)?"

A. Probably not.

Q. "Or does it violate fire code to have exterior, load bearing walls with open cavities, despite blocking?"

A. Talk to your local code official. Most builders still install drywall on the interior side of the studs.

Q. "I've been enamored of mineral wool ever since hearing some Lstiburek talks on insulation/wall assemblies; is it competitive in cost with EPS?

A. No. It usually costs more. If you can obtain recycled or reclaimed EPS, the price for the EPS will be many times less than the mineral wool

Q. "If we're talking about insulating a wall cavity, and the complicating factor is thermal bridging, why not consider a double stud wall? 2x4s 24" OC staggered, should be stronger than 2x6, too. Is it significantly more expensive, or hard to find contractors who can do it?"

A. Lots of builders specify double-stud walls. For more information, see How to Design a Wall.

Q. "On wall cavity insulation, I've seen dense-packed cellulose held in by some sort of clear plastic sheeting (for inspection, before the drywall goes up). Doesn't that prevent the dry-to-the-inside capability that is supposed to be more attractive for cellulose?"

A. The fabric you are describing is called InsulWeb. It is air-permeable and vapor-permeable, so the answer is: No, it doesn't prevent inward drying. For more information, see How to Install Cellulose Insulation.

-- Martin Holladay

Closed Cell vs. Driven Wind Infiltration

A comment; Port Huron sits on a lake, and is definitely well in climate zone 6; you have to go south of Detroit generally to get into 5. It is often subject to extended 50+ mph winds in winter.

Would the air sealing capability of closed cell foam in this climate readjust the decision on insulation use? I am in Detroit, a teeny bit warmer but just as windy so closed cell seems popular for this reason.

Thank you, Mark Reynolds

Insulation Information Black Hole

I too have found myself getting sucked down the black hole of insulation information for a new construction. I am going to be building a new home in North Central Massachusetts. The wall will be 2x6 with Zip System Sheathing as my air barrier. I can't decide if I should go with R21 Fiberglass batts, dense cellulose or dense pack fiberglass? The dense packing is coming in at a bit of premium to the batts? Is the dense pack worth the premium? Would I notice a difference between the 3? Would I notice a difference between loose fill cellulose and loose fill fiberglass in my vented attic space? It was pretty obvious that a made sense to use a 12" raised heel truss because I gain Rvalue over the top plate. With this decision I get essentially the same R value and my air barrier is the exterior sheathing.

Response to Kurtis Cormier

Kurtis,

When comparing cellulose, blown-in fiberglass, and fiberglass batts, the decision always comes down to installation quality. All three of these insulation materials can work well, as long as the team has paid attention to airtightness, and as long as the insulation installers are conscientious.

Conscientious installers of fiberglass batts are quite rare, but they exist. For more information on this issue, see Installing Fiberglass Right.

Blown-in products like dense-packed cellulose or dense-packed fiberglass are harder to screw up than fiberglass batts, but it's possible to screw up anything. You want to choose insulation installers who sound like they know what they are talking about, and who have a reputation for quality work.

-- Martin Holladay

Neighborly choices

Colleen,

We are located in South Haven, Michigan, and are experiencing much the same choices and difficulties. We are also self-contracting and DIY building our new barn home with little insight from builders who think this building system/style is a waste of time and "un-necessary." Most have never heard of numerous products we are using (Roxul, Prosoco, Intus or any windows w/ U-factors well under 0.20 and high SHGC). They all think we are looney!! GBA is our saving grace :-)

We are aiming for a wall R-value of at least 7.5 and have elected the following wall composition from inside out: 2x6 wall packed with either cellulose or Roxul ComfortBatt R-?, plywood (vs. OSB) sheathing w/Prosoco painted on, Roxul ComfortBoard 80 x3 inches or Johns Manville CI Max® 1-1/4" Polyiso Foam Insulation, 1x3 furring, metal siding. We knew right away that we wanted to stay as "green" as possible in construction to avoid off-gassing of synthetic materials, and, though it may cost a bit more, it will be worth the positive footprint and peace of mind in the end.

Response to Brant Quinn

Brant,

You write that you "are aiming for a wall R-value of at least 7.5." Fortunately, the details you describe will give you an R-value that is much higher than that -- because R-7.5 would be less than code minimum requirements.

One of your proposed alternatives -- installing 1 1/4 inch of polyiso on the exterior side of an insulated 2x6 wall -- is a little marginal. Your location appears to be in Climate Zone 5 -- close to the border of Climate Zone 6. If you are in Zone 5, the minimum R-value for any exterior rigid foam installed on a 2x6 wall is R-7.5. Polyiso doesn't perform well at cold temperatures -- call it R-5 per inch (at best) in cold weather, giving your rigid foam layer an R-value of about R-6.2, not R-7.5.

If you want to build a wall that performs well in Climate Zone 6 -- after all, your location is near the border -- then the rigid foam layer needs a minimum R-value of R-11.25.

Here are links to articles you should read:

Calculating the Minimum Thickness of Rigid Foam Sheathing

Cold-Weather Performance of Polyisocyanurate

In Cold Climates, R-5 Foam Beats R-6

-- Martin Holladay

Response to Martin Holladay

As always, thank you for your input, Martin. As noted, we were deciding between the 1-1/4" Polyiso Foam Insulation and the Roxul ComfortBoard 80 x3 inch thickness (R-12). Looks as though the Roxul will once again be the better choice. We are having a very difficult time sourcing the 3" thickness, even though Roxul manufacturing said that local distributors should be able to get it. Therefore, we are planning on doubling up on the 1.5" boards (R-6) to get the 3" (R-12). With this wall composition in mind, any suggestions on what R-value we should shoot for in the Roxul ComfortBatt interior walls and/or cellulose?

You may have thoughts on this as well: We are also planning on metal/steel siding; however, I just found out that our selection needs to be installed over a solid substrate, not just furring strips. Any input on whether it is wise to put another layer of plywood sheathing over the furring strips to support the metal siding or should we elect a different siding/manufacturer that can be installed over the furring?

-Leslie Q.

Response to Brant Quinn

Brant,

This is an aesthetic decision, not a building science decision. If you have your heart set on a certain brand of steel siding, you have to follow the manufacturer's instructions.

Personally, I might choose a different siding that I could install on furring strips. But it's not my house.

-- Martin Holladay

Response to Martin Holladay

I sincerely appreciate the input either way, Martin. We just wanted a second opinion to make sure that the idea of an extra layer of plywood would not create a problem with the function of the wall system. Thank you and best regards!!

-Leslie Q.

Insulation isn't the only

Insulation isn't the only overwhelming area of building a new home. There are endless space heating, window, and other options too. More so, you can't just pick the best insulation then move on and pick the best furnace; the home in total needs to be the highest value to the homeowner. We've found that nearly every homeowner wants maximum return on a minimized investment. Some homeowners care about the environmental side and will pay more, but all homeowners care about money. We stepped back from building and began advising a few years ago and it's been an incredible way to reach more homeowners and builders across the entire nation. Between energy modeling software (e.g. REM) plus build cost optimization software (eFree SmartSpend), the perfect mix of building components can be identified up front without any guesswork. It answers all of the questions without any bias from a subcontractor "selling" a particular product.

Log in or become a member to post a comment.

Sign up Log in