Basement wall insulation can be placed on the exterior side of the wall, on the interior side of the wall, or on both sides of the wall. In this article, I’ll discuss the three most common ways to insulate a basement wall from the interior. (For a comprehensive discussion of basement wall insulation, including exterior basement insulation, see my 2012 article, “How to Insulate a Basement Wall.”)

General principles

Make sure that your basement is dry. Before installing any interior wall insulation, verify that your basement doesn’t have a water-entry problem. For more information on this topic, see “Fixing a Wet Basement.”

R-value minimums. In Climate Zones 3 and higher, basement insulation is required by the 2012, 2015, and 2018 International Residential Codes as follows: at least R-5 in Climate Zone 3, R-10 in Zone 4 (except Marine Zone 4), and R-15 in Marine Zone 4 and Zones 5, 6, 7, and 8.

That said, local codes may differ from these general guidelines, so it’s worth asking your local building department about minimum R-value requirements in your community.

Note that the IRC lists two different R-value requirements for basement walls: a lower number (for example, R-15 in Zone 5) for continuous foam, and a higher number (for example, R-19 in Zone 5) for “cavity insulation”—usually interpreted as fluffy insulation like fiberglass installed between studs. Since it is inadvisable to insulate a basement wall with fluffy insulation like fiberglass unless the wall has first be insulated with a layer of continuous rigid foam or spray foam, it’s generally best to focus on an approach that uses continuous insulation, and to ignore the “cavity insulation” approach.

Insulation choices. On the interior side of a basement wall, all three common types of rigid foam insulation—polyisocyanurate, expanded polystyrene (EPS), or extruded polystyrene (XPS)—perform well. That said, green builders usually avoid the use of XPS,…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

89 Comments

What is the sill sealer doing in the illustration with the foam ?

It's keeping any moisture in the slab from wicking up into the wood or the polyiso, both of which can absorb moisture. It's a nice simple solution to that problem.

Normally I glue (few fasteners) .. I'm always doing heated slabs with insulation and VB. So, I hope my moisture is controlled. With the sill foam strip you have to power nail.

You glue the bottom plate instead of nail? Is that just to avoid the concrete fasteners? Specific glue preferred?

Does sill sealer need to be placed under poly iso if there is a 1" gap off the ground filled with one part spray foam?

Will,

Q. "Does sill sealer need to be placed under polyiso if there is a 1 inch gap off the ground filled with one-part spray foam?"

A. No. Although some others may disagree, I wouldn't worry about wicking with your detail.

Dear Martin: Based on personal experience and lab tests, I have to disagree. Polyiso foam board absorbs water like a sponge. Based on personal experience, water will travel up polyiso foam board from an exposed edge at least 3 inches. I wish someone would do a real test to determine how significant this problem is over time. For example, does moisture continue to migrate up a polyso panel? Or not? How exactly does this affect R-value?

It is also important to note that DOW created a new version of their Foamular XPS foam board with significantly lower GWP (claimed 90%). In short, market pressure worked!

This new version is called Foamular NGX. XPS does not absorb water and the R-value does not drop along with the temperature, like polyiso. See:

http://www.businesswire.com/news/home/20200807005036/en/Owens-Corning-Introduces-FOAMULAR®-NGX-Insulation and

http://www.owenscorning.com/en-us/insulation/commercial/foamular-ngx

Mark, Martin wasn't saying that moisture in polyiso is not a problem. Rather, he was saying that the specific detail that someone proposed to prevent that seemed adequate.

Yes, it is good that lower GWP XPS is available. There was a story about that a couple months ago:

https://www.greenbuildingadvisor.com/article/xps-makers-announce-more-planet-friendly-formulations

It seems like it's still hard to get your hands on, but I'd be curious to hear whether people are seeing it on the shelves at Home Depot in any of the regulated states yet.

Mark,

I agree with Charlie's points. The development of XPS products with better blowing agents -- that is, blowing agents with a lower global warming potential -- is, indeed, good news. Let's hope that in a short time, these products dominate the market, so that it will become easier to recommend XPS to green builders without caveats.

“Basement wall systems should never include polyethylene sheeting—neither between the concrete and the foam insulation”

There are diagrams on fhb/gba that recommend installing the vapor barrier from the ground, up the wall just below the sill plate in crawlspaces. This seems like a contradiction unless there is something inherently different with the basement. We just had such as installation done, is this now not recommended? I thought polyiso wasn’t supposed to be in direct contact with ground/concrete?

Reference: https://www.greenbuildingadvisor.com/article/building-an-unvented-crawl-space

Carson,

You're right; the recommendations for crawl spaces and basements are contradictory. I wrote my crawl space article a long time ago, and included advice on polyethylene that was commonly expressed by sources I respected. In retrospect, I now believe that including polyethylene on crawl space walls, between the foundation wall and the rigid foam or spray foam, serves no useful purpose.

That said, polyethylene in that location in a crawl space doesn't really cause any harm. So either way, don't sweat your decision.

Crawl spaces tend to be more damp than basements, for a variety of reasons. (One reason: basements are more likely to have mechanical equipment like furnaces and water heaters than basements.) For basements, I would stick to my recommendation -- no polyethylene on the wall.

The worst place for polyethylene on a basement wall would be between the drywall and the fiberglass-insulated studs. This is a very bad idea, and plenty of remodelers in Minnesota know what lurks behind poly in that position: mold and soggy fiberglass. Such assemblies have filled many dumpsters.

Our local building inspections require 6 mil poly on any proposed basement (and above ground) wall assembly unless it is 100% foam insulation to specified thickness/R value/vapor. New Brunswick Canada. We just did one as described in your Assembly 2, but with 6mil between studs and drywall. What reference (code) should I use to have "the talk" with our inspector/permit application process next time?

Ex in Reno,

First of all, you might want to read this Q&A thread:

"Poly and Canadian Building Codes."

Second, here's my advice: If a stubborn code official wants 6 mil polyethylene in the wrong place, do your best to convince the code official to accept a variable-permeance material like MemBrain instead of poly. In this location, the MemBrain is unnecessary, but at least it won't cause as much damage as polyethylene.

My last two projects were in the city and when dealing with 16' wide spaces -- doing the 2" gap and 3.5 stud wall is a lot of space to give up when you need the lower level for living space.

It's the same with my current project .... while not in the city it's in an historic village and I was restricted in building size. The lower level is living space and the architect wanted to minimize the look of the foundation. I'm in zone 4. I did the R10 (-2x) .... there is not much of the foundation out of the ground. This is only a one story so we could use a strengthened 8" wall. Inches matter sometimes.

Yeldog,

I agree that inches matter sometimes. (That said, I have no idea what you mean by "I did the R10 -2x." Sounds like an algebraic equation.)

If inches matter, the best solution is polyiso topped by 1x4 strapping.

If you're really space constrained, a few options to minimize the thickness of your build-in:

- THERMAX polyiso with taped seams (see Marc Rosenbaum's blog, https://blog.energysmiths.com/2011/08/basement-insulation-part-3.html)

- PVC Z-furring attached to the wall, with spray foam between--unlike metal studs, doesn't cause thermal bridging problems (http://ecostud.com/category/z-furring)

- Prefabricated panel system like InSoFast (https://www.insofast.com/lc/basement-insulation-panels.html)

- Rigid foam with 1-5/8" steel studs for services; leave stud cavities empty. Unlike wood studs, you can get them to stay straight even at this depth. Could also use this for a spray foam retrofit.

Contractor already put stud walls against basement wall, no sill sealer underneath or vapor barrier behind. Is the best solution cut and cobble with eps? I suspect I can’t put foam over the studs, as there would be no drying potential other than back through the wet concrete.

Carson,

Q. "Is the best solution cut and cobble with EPS?"

A. No. The best solution is to dismantle the stud wall. Use a Sawzall to cut some of the nails -- that should allow you to reuse the studs.

Oi, not sure how that’s going to go over with the contractor. This is just so I can put foam behind them instead of in them, and rebuild the stud wall? This is for a tiny engineer spec’d utilty room in the crawl. The walls are all well below grade.

Carson,

Of course, the decision on how to proceed is up to you. I'm a former builder, and my instinct is to side with builders in most disputes. But I think you are a little too worried about the contractor's feelings in this case. He or she should know better.

thanks Martin, going to try to remove it and go with your strapping over foam approach instead of the studs.

I also had to do this. It's not that bad to get done, especially on a new build.

Question--are the studs tight against the concrete wall, or is there a gap? If there's a gap, closed-cell spray foam might be an option to consider. Also, if you can simply remove fasteners to the slab and the framing above, could you simply "shift" the wall inward a few inches for this type of retrofit?

unfortunately, they are tight against the wall. Cutting out part of the walls to move them inward sounds like a good suggestion and I may try that, though that may end up being more work than removing them entirely and using furring strips against the foam. It sounds like I would also need to raise them a bit and fit sill sealer to the bottoms. I'm not sure what the primary issue is - I assume moisture/mold potential of the wood against the concrete. The walls are far enough below grade I don't think thermal losses would be high enough alone to warrant the effort.

Carson,

Your original question asked about "the best solution," and my answer was based on your desire for the best solution. If you are willing to accept the second-best solution, cut-and-cobble will work.

Fair enough, I suppose I should have worded it "what would you suggest I do"? Though it sounds like it may be the same answer. For cut and cobble, would the concern primarily be mold/rot of the studs in contact with the concrete?

the air is exchanged with the house, so mold issues are big ones.

Carson,

Without continuous insulation, several risks increase. There will be more thermal bridging, as you note, and there is a risk of rot (due to the fact that some of the studs are in contact with the damp concrete). Moreover, the cut-and-cobble approach raises the risk of air leakage due to the high number of seams that need to be sealed -- and this raises the risk that interior air will contact the cold concrete. I'm not saying the risks are significant, but there are several factors that make this the second-best way to proceed as opposed to the best way to proceed.

The diagrams show 1/2" plywood fire block. My understanding is that a minimum of 3/4" plywood or 2x lumber are required as fire block.

There are a few other option, including 1/2" drywall, but you're correct that the IRC does not allow 1/2" plywood as fire blocking: https://codes.iccsafe.org/content/IRC2015/chapter-3-building-planning#IRC2015_Pt03_Ch03_SecR302.11.1

Robert,

Good catch! You're right. I regret the error. The labels on the illustrations have been corrected. Thanks for your help.

Thanks Martin for all your work over the decades educating us about a wide range of sustainable building issues. Thanks also to progressive builders like Maines and others who share their knowledge. Great community here.

I'm struggling to understand the need for below grade insulation. If the basement ground is not typically insulated, and in crawlspaces it's said to not be worth insulating if the walls are, what is the difference between a below grade wall and the floor? Is it purely to reduce moisture? If so, why isn't the slab the same condensing surface with the same temperature as the below grade portion of the wall?

Carson,

Q. "What is the difference between a below grade wall and the floor?"

A. During the winter, there is a temperature gradient in the first few feet of soil. The actual temperatures depend on your geographical location, the winter weather, and the depth of the snow cover (if any), but I'll describe what's possible in Vermont on a January day when there is 4 inches of snow on the ground. Let's assume that the outdoor air temperature is 0°F. Directly under the snow, the top few inches of soil might be 15°F. Two feet lower, the soil temperature might be 32°F. At 5 feet below grade, the soil temperature might be 40°F. Under the basement slab, the soil temperature might be 50°F or 55°F.

Now let's look at the foundation wall. The top 12 inches of the foundation wall is exposed to the outside air -- so that section of the wall is at 0°F. The concrete is even colder than the top few inches of soil. Since the top of the concrete is so cold, you'll see a layer of frost on the interior of the basement wall, in a band near the top of the wall (assuming, of course, that the basement wall is uninsulated).

If you go down to the bottom of the wall, the concrete might be at 50°F.

The temperature gradient I just described is the reason why basement walls -- especially the tops of basement walls -- are so much colder than basement slabs during the winter.

Martin,

Would phenloic foam rigid insulation for the foundation walls be even more ideal since it has a higher R-value per inch and avoids the flame retardants that are in some (most?) other foam plastic insulation panel products?

https://www.greenbuildingadvisor.com/article/phenolic-foam-insulation-revisited

Also, how much does the vapor permeance of the insulation matter? I have always thought that with ccSPF the low vapor permeance was fine / good since it aggressively adheres to the foundation wall filling every nook and cranny and there is much less chance for water vapor to make it through the foundation wall at all.

When applying any rigid insulation panel, in recent years, I have come to think that it is important to use a material that has more vapor permeance and allow drying to the interior since those insulation panels are not continuously adhered to the foundation wall, I believe water vapor could more easily get through the foundation wall and into the tiny air interface between the back side of the insulation panel and the face of the foundation wall. Thus I ponder whether foil faced polyiso insulation in particular should be avoided since foil has basically zero vapor permeance?

Attached are photos from a basement that was remodeled about 20 years ago in Minnesota. The basement was build in the 1970's and has moisture resistant parging on the exterior but not a robust waterproof membrane that we normally used on new homes today. Roof overhangs are about 3 feet deep, soil is very sandy and slopes away from the house well. Despite all of this and 20 years of good performance, this past summer they had record rain of about 20" in the span of about 2 weeks and the lower portion of the paper faced drywall got moist and moldy. After removing the drywall and some of the 1.5" thick foil faced polyiso insulation, it appeared to me that the foil on the polyiso insulation has some corrosion and evidence of having seen moisture more times over the past 20 years. The electrical box appears that way also. Frankly I was a little surprised to not see mold on the back side of the foil faced insulation and the face of the CMU block foundation, but I am also curious if the alkalinity of the concrete deters mold growth on its surface as well, even if it does get moist?

We were thinking of replacing the foil faced polyiso on the lower portion of the wall with EPS, non-foil faced polyiso or phenolic foam rigid insulation and then glass matt faced drywall this time, with the logic that more vapor permeable materials would allow the assembly to dry to the interior more quickly to better prevent any future mold risk.

Also considering the removal of the bottom 2x2 plate that is in contact with the slab and re-install some 2x2 blocking 1.5" higher. Fill the cavity of the 2x2 removed with rigid insulation, hold the bottom of the new drywall up off the floor .5" minimum and then install base board trim again.

The house does have a high velocity A/C system in it and in-floor heat system, but the owner does not always run the A/C, since he likes to save energy and is willing to suffer through the heat and humidity many times in the summer. Thus we are planning to have a portable dehumidifier in this basement room from now on with its humidistat set to about 30% RH as well to ensure the moisture levels are more actively managed in the future.

Thanks in advance for any thoughts / advice you may have about all of these questions and our proposed approach to fix this basement.

-Marc

Marta,

Q. "Would phenloic foam rigid insulation for the foundation walls be even more ideal since it has a higher R-value per inch and avoids the flame retardants that are in some (most?) other foam plastic insulation panel products?"

A. I have no direct experience with, or opinion on, the characteristics of phenolic foam insulation. GBA readers who have tried to buy some have discovered that the product is mostly unavailable. If any GBA readers other than Peter Yost have managed to buy some phenolic foam insulation, I'd be interested to hear of your experience.

Q. "How much does the vapor permeance of the insulation matter?"

A. Not very much, since useful thicknesses of closed-cell spray foam or rigid foam insulation are all vapor retarders or vapor barriers.

Q. "I have come to think that it is important to use a material that has more vapor permeance and allow drying to the interior."

A. I disagree strongly with your conclusion. There is absolutely no benefit to inviting moisture to flow from the damp soil outside your home into your basement's interior. For more information on this issue, see "Joe Lstiburek Discusses Basement Insulation and Vapor Retarders."

Concerning the 20-year-old remodeling job in Minnesota: Everything looks pretty good to me. Of course, water entry into a basement is undesirable, and water entry problems should be addressed before attempting to insulate the interior of a basement wall. A little mold on the foil facing of your 20-year-old polyiso is neither surprising or alarming. After all, there is lots of mold in your soil. As long as the mold is on the exterior side of the polyiso, and you pay attention to airtightness, the mold on the aluminum foil is no more alarming than the mold in the soil adjacent to your foundation.

Martin,

Thanks for the replies. All very helpful, as usual!

One last point--definitely agree with installing a dehumidifier. However, setting it for 30% RH will make it run like crazy--it will run nonstop and never get there (except maybe in winter, if you have a lot of air leakage). In general, a rough target RH for basements (setpoint for dehumidifier) might be in the 50-60% RH range.

I could read about basement insulation all day. Thanks Martin for all the work you’ve done to allow me to do so.

After many enjoyable hours reading about basement insulation in old brick buildings, I’m doing a bit of a combo of these methods. Cut and cobble doesn’t seem like quite the right descriptor, but it’s close. Maybe someone else has a name for what I’m doing (continuous cobble?).

It’s an old, 1930’s brick building in Chicago with a poured concrete foundation. Due to some bumpy walls, old house quirks, an overhead sewer along the walls, and the building schedule, I’m doing most of the wall in a continuous layer of 2” of EPS but leaving the top, bottom, rim joists and various gaps here and there to be spray foamed in with a froth pak later after the framing goes up.

It’s helped us save money while also being be flexible in terms of creating a continuous layer while not having to stress about the areas that are difficult to attach rigid to (like the very bumpy rim joists, or the places where we did foundation crack repair). I’m being careful closing up the seams b/w the sheets of EPS, using foam and tape. 3M All-weather flashing tape has been great with the R Tech EPS boards we’re using (shiny foil facing inward).

The one thing it seems I’ve neglected is the sill seam. Given that the walls should be well sealed and the base plates are pressure treated, is this something I should be concerned about? Basement has been very dry to date.

And, for those interested in greater detail or how I’m dealing with my embedded joists there are more details/questions/answers in this post:

https://www.greenbuildingadvisor.com/question/embedded-joists-in-cold-climate-brick-basement-insulate-heat-borate

Ikibbe,

Q. "The one thing it seems I’ve neglected is the sill seam. Given that the walls should be well sealed and the base plates are pressure treated, is this something I should be concerned about?"

A. The sill sealer shown in the illustration (between the bottom plate and the concrete slab, and between the rigid insulation and the concrete slab) is a nice detail, but it's not strictly necessary. If you omitted it, I wouldn't lose any sleep if I were you.

For more information on dealing with embedded joists, see "Insulating Basement Walls With Embedded Joists."

Thanks Martin. That’s exactly what I hoped to hear.

For my joists I’m doing 1” of spray foam, and borate rods in the joist ends on the northern wall. Cheers!

Martin,

Great article, and incredibly timely for me - I'm working on a basement insulation plan for our home right now... Coastal Rhode Island, climate zone 5, reasonably heavy silt loam soils with high water table.

1. Would any of your best practices change if the basement had an interior perimeter drain system with sealed sump pump, etc? That is what I have in our basement - it has done wonders to eliminate our unwanted "indoor swimming pool"!

2. A specific question on that front - our basement is basically two basements - original rubble foundation from 1830's, newer addition has a poured concrete wall foundation from 1995 or so. The rubble wall leaks water consistently when soil water levels rise. Typically October - May here in Rhode Island. When the perimeter drain was installed a few years ago, poly sheeting was installed from the drain and up the rubble wall to guide the weeping water down the irregular wall into the drain below. Much like this assembly detailed at the end of this article by Steve Baczek back in 2015:

https://www.greenbuildingadvisor.com/article/how-to-save-an-old-house

Our plan was to use closed cell spray foam over the poly sheeting and up into the rim joist cavities. Our thought was that by leaving the poly sheet up against the wall, when the ccSPF is applied, the foam won't plug the perimeter drain, keeping a path for the water to run to the sump. Would you advise against this now with your anti-polyethylene sheeting recommendations?

3. And do you have any thoughts on the use of chicken wire in Steve's detail from that 2015 article? First time I had seen that and it seemed like a neat solution! That is, if it works and doesn't compromise the spray foam structure somehow.

Thanks so much!

A. Morley,

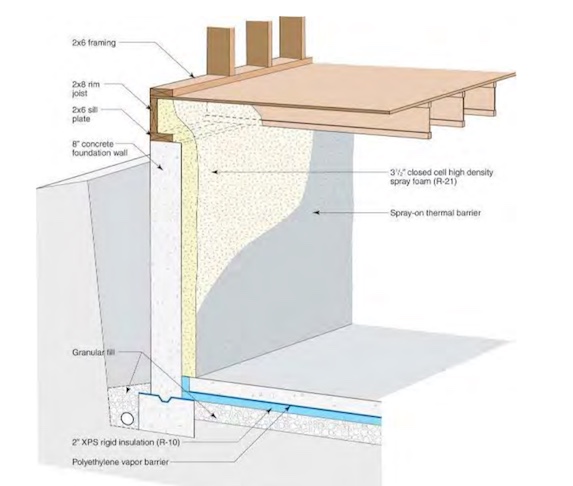

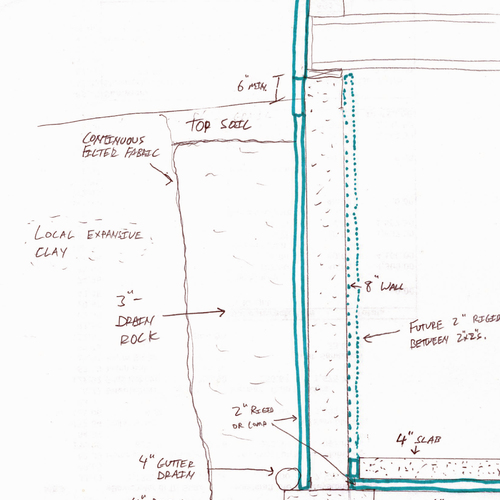

Your description of the interior French drain sounds fine; it's similar to the detail that GBA has provided for years (see attachment).

I think that Steve Baczek's trick -- installing chicken wire before spraying closed-cell foam against the polyethylene -- makes sense.

Many thanks!

Are there any options that allow you to insulate, but not require sheetrock?

Draft Hunter,

Q. "Are there any options that allow you to insulate, but not require sheetrock?"

A. Yes. Mineral wool insulation can be used as a thermal barrier. (Of course, you should check with your local building official to make sure that he or she agrees with this opinion.) The option is mentioned in my article, "Thermal Barriers and Ignition Barriers for Spray Foam."

More information here: "Use of Rockwool stone wool as a Thermal and Ignition Barrier."

If you go this route, you would need to build a 2x4 stud wall on the interior side of your rigid foam or spray foam insulation, and fill the stud bays with mineral wool, in compliance with the Rockwool recommendations found in the linked document.

Martin, I'm curious why you are not mentioning Dow Thermax as a code-compliant solution for basements. Unless something has changed, I believe it still meets the IRC criteria for thermal and ignition barriers: https://www.dupont.com/content/dam/dupont/amer/us/en/performance-building-solutions/public/documents/en/meeting-the-fire-code-with-continuous-foam-plastic-insulation-43-D100637-enUS.pdf.

Michael,

Thanks for mentioning another good solution. You're right, of course.

I have edited my article to include a mention of Thermax, as well as a mention of the use of mineral wool insulation as a thermal barrier.

Martin, phew--I was worried that there had been a code change or building science development I wasn't aware of, which is not unusual.

What about skipping the rigid foam altogether and just using comforboard? I’m guessing that would require a vapor barrier first? Thank you.

drafthunter,

I think the concern there is that warm air could move through the mineral wool and condense on the interior side of the vapor barrier, so a layer of foam of sufficient thickness would be required to be against the wall first.

Draft Hunter,

Carson is correct. The problem has nothing to do with vapor barriers; the amount of vapor diffusion isn't really concerning. The problem arises when indoor air contacts the cold concrete, leading to condensation and moisture accumulation. Air-permeable insulation materials like fiberglass or mineral wool don't stop air flow.

Attempts to create a perfect air barrier on the interior side of fluffy insulation usually fail. The only robust solution is to use rigid foam or closed-cell spray foam against the concrete. That way, the first condensing surface--the interior surface of the foam--stays above the dew point. (In other words, it's warm.)

For more information on this issue, see "How to Insulate a Basement Wall." (Scroll down until you see the section that begins with the heading, "Can I insulate on the interior with fiberglass batts, mineral wool batts, or cellulose?")

Great article by GBA and @MartinHalladay as always. I have learned a lot from GBA as a builder the last 2 years and happy to say, I've totally reworked my approach to basements based largely on research on GBA and some sustainable building conferences.

I get asked a lot about basements myself and one question I get here in New England is what to do about old junk slabs or dirt floors, particularly if someone is preparing to finish a basement. Part of my prescribed answer is now to include a layer of EPS foam below the slab and thermally break the slab at the walls.

This article appears to be primarily geared towards retrofits, however probably worth mentioning the ability to address slab insulation properties if someone is doing a full basement makeover. By my longevity calculations, it's getting harder and harder to justify building over even a decent junk slab knowing how thin it is and that it likely lacks proper drainage and for sure insulation underneath.

Keep up the good work here guys! And @CarsonB, not even a questions on a smaller utility wall space, yank those studs and do it right! Good luck.

Joe,

You wrote, "One question I get here in New England is what to do about old junk slabs or dirt floors, particularly if someone is preparing to finish a basement. Part of my prescribed answer is now to include a layer of EPS foam below the slab and thermally break the slab at the walls."

That's good advice. At a minimum, a dirt floor needs a layer of polyethylene. And if a homeowner is considering the installation of a concrete slab -- either over existing dirt or to replace a cracked older slab -- then a continuous layer of rigid foam under the new slab makes sense.

For more information, see these two articles:

• "All About Basements"

• "Fixing a Wet Basement"

Martin,

Not sure how you have time for all of of this, but it's amazing and appreciated. Yes, forgot to mention the layer of poly. I would also try to integrate a radon mitigation system anytime under a new slab in New England.

Cheers,

Joe

"@CarsonB, not even a questions on a smaller utility wall space, yank those studs and do it right! Good luck." Might have to do it after home complete, but yeah that's my plan. New home and already planning out some remodeling:)

Thanks very much for this article. I've already put of 2.5 inches of EPS against my cement walls, built 2x4 stud walls against the EPS and plan to fill the bays with either mineral wool or spray foam. I have two questions:

1) I taped the seams of the EPS with Tyvek tape, which is does not seem to be holding on well in some places. I can re-tape the seams without too much difficulty. Any recommendations on tape that will stick well to EPS?

2) Is this thickness of EPS a good enough vapor barrier? Reading the comments above got me thinking that the EPS may have too high of a vapor permeance. (I'd much rather use mineral wool rather than spray foam in the bays.)

Steve,

There are various densities of EPS. The cheap stuff has low density, with visible beads -- that stuff is crumbly and hard to tape. Better quality EPS has a smooth finish, and you can't see individual beads -- and this higher quality EPS is easier to tape. I would try either 3M All Weather Tape or Siga Wigluv tape.

I wouldn't worry about vapor diffusion through 2.5 inches of EPS. Vapor permeance will vary depending on foam density, but perhaps 2 perms is a good guess.

No need to use spray foam between the studs; the mineral wool batts should be fine.

OK, thanks again!

As usual, this is more information than I was ever expecting.

I'm in a 100+ year-old attached brick house in Brooklyn. My finished basement includes my home office. This room is at the front of the house, and we've recently ripped out some molding drywall and wood floors (yes, the previous owners finished their basement with wood flooring) due to some grading and downspout issues just outside the windows.

https://photos.app.goo.gl/UxMVGAEfEzqnSZGk6

My current plan, and remaining issues:

- The current insulation is loose fiberglass. I'd like to replace it with something better. Rockwool sounds like a good choice, given that I need to fit it around the brick ledge. I also don't want to replace all the studs and have the builder remove and replace the electrical conduit.

- On the far right of the second photo, you'll notice a blue nozzle. It's the interior drain for the outdoor spigot on the other side of the wall. Prior to the demolition, access was provided via a very drafty access panel. I need some plan to preserve access while keeping out the cold air.

- I need to pick a better flooring material. Martin, I saw your note in a previous article about providing a layer of rigid foam board above the slab. As for the top layer, an architect across the street recommended luxury vinyl faux wood panels. Any thoughts on the best material?

- The room has radon, thanks to the two sewer pits. I'm working with a builder to pour concrete over the loose soil and design a tight trap door. Hopefully that will be sufficient to get the room down to safe levels.

Brooklynite,

I'm basically in the same climate zone, I'm in suburbs of NY. I have gone back and forth with the vinyl on concrete idea. From what I understand you will get 2 different opinions. Either vinyl will be fine directly on concrete or you will trap mold underneath. I'm not sure what to believe, but if conditions are right I would assume it is fine. I wanted to cover my floors with vinyl and just turn the heat up in winter but I think you need insulated walls for vinyl to work on concrete.

I have a stone and mortar wall but it is covered with a parge coat of stucco making the wall flat. The article says you can't use rigid foam with stone and mortar walls but that's only if you don't have a flat surface correct?

The sill sealer can be eps foam correct? I'm going to use furring strips so I don't think I need it. Would this sill sealer also apply to interior walls and doorways that have a pt bottom plate?

> or you will trap mold underneath

I'm hoping to prevent this by following the guidelines here:

https://www.greenbuildingadvisor.com/article/installing-rigid-foam-concrete-slab

Right now my plan is to layer like so:

---------- Vinyl planks: between 1/8 and 1/4"

---------- OSB: ~5/16"

---------- 6mil polyethylene

---------- Expanded polystyrene board ~.75"

---------- Slab

This is thinner than Martin recommends, but I'm in a situation where every 1/4" counts.

I would think you can cut down to half inch insulation in that climate zone and be fine if every 1/4 inch counts. Are you putting 6 mil poly over your insulation? I think that belongs over the slab in that situation

Hello All,

I have been reading your comments and find them very helpful. I am trying to finish an area of the basement for the kids while we do virtual learning -everyone needs more space these days.

We are in Atlanta and our basement is below grade. We have concrete walls and have had a few instances of water entering through cracks that have since been patched and ground re- graded.

I went today to Home Depot and found Foamacular which seems to be a good option. If i am understanding correctly, we would apply an adhesive to the XPS polystyrene, then onto the walls and then drywall, and mineral wool in between the rigid foam board and drywall would not be necessary. The issue is the walls are already framed, but there is a gap up to 2 inches so hopefully we can remove some framing to get the pieces in between and attached properly. How thick of XPS? .5-2 inches for climate zone 3?

Any other thoughts? I am opposed to using spray foam as we already had a bad experience in the main floors of the house. My biggest concern is mold/moisture control and using something green with low/no VOC. Thank you for your time.

>"We are in Atlanta..."

Atlanta is in US climate zone 3A, where the IRC 2018 code minimum is R5 continuous insulation. See TABLE N1102.1.2

https://codes.iccsafe.org/content/IRC2018/chapter-11-re-energy-efficiency

An inch of foil faced polyiso is labeled R6, an inch of XPS (Foamular) is labeled R5 (more on that below), and 1.5" of Type I EPS would be R5.8.

>"My biggest concern is mold/moisture control and using something green... "

The inch of Foamular would meet the letter of that code, but it's the least green option. XPS is blown with a high global warming potential HFC soup, the predominant ingredient of which is HFC134a, an extremely powerful greenhouse gas. As the HFCs leak out over a couple of decades the performance drops- it's only warranteed to 90% of labeled value after 20 years, which would be R4.5. At full depletion it's performance drops to R4.2, the same as EPS of similar density.

By contrast EPS is blown with low impact hydrocarbons, usually isopentane, most of which leaves the foam and is recaptured at the factory, not vented to the atmosphere. While at ~R4/inch it takes at least 1.25" to meet code-minimum it seems you have the space. R for R XPS has an order of magnitude greater global warming impact as EPS. See:

https://materialspalette.org/wp-content/uploads/2018/08/CSMP-Insulation_090919-01.png

Similarly, foil faced polyisocyanurate is blown with low impact hydrocarbons, and comes in at about half the impact of closed cell polyurethane in that chart.

Most Home Depot stores that carry Foamular XPS also carry R-Tech's Type-1 EPS (R3.85/inch) as well as Dow Tuff-R polyiso (R6.5/inch), both with facers. If you with polyiso be sure to keep the cut bottom edge of the foam a half-inch off the slab, since polyiso is somewhat hygroscopic and can wick moisture out of a damp slab. (This would be important given the history of wall leakage.) If EPS that doesn't matter. Doubled up 3/4" EPS would be pretty easy to slip in to the 2" nominal space, but you doubled up 1" may work, depending on how generous that 2" turns out to be, and how flat the walls are.

Thank you so much.

Sounds like the R tech doubled up will be our best all around solution ?

We were hoping to do a concrete stain on the slab as the final finish. Industrial look.

This article is timely as I'm figuring out the basement insulation details for our new construction home in Des Moines, IA (climate zone 5).

I'm looking over a bid from a local company and they have spec'd an option to use 3 - 3.5" open cell spray foam in 2x4 furred basement exterior walls. This sounded great, until I saw the following mentioned under Assembly #3:

"(Note that open-cell spray foam is too vapor-permeable to be suitable for basement walls.)"

I then read News Story #2 in https://www.greenbuildingadvisor.com/article/joe-lstiburek-discusses-basement-insulation-and-vapor-retarders, and I'm even more confused. It seems to suggest that the vapor permeability isn't that important.

I'm hoping someone can help me understand if open cell spray foam would be appropriate for a basement in climate zone 5?

Burke,

One of the main points of the article you linked to ("Joe Lstiburek Discusses Basement Insulation and Vapor Retarders") is that below-grade concrete walls (basement walls) don't need to dry inward. There is no reason to allow moisture to flow from the concrete wall into your basement. So there is no need for low-permeance insulation in this location--in fact, low-permeance insulation (like open-cell spray foam) causes far more problems than insulation (like closed-cell spray foam) that restrict the movement of water vapor.

So this is a consistent message: Use closed-cell spray foam, not open-cell spray foam, in this location. Closed-cell spray foam will do a better job of preventing soil moisture or moisture in the concrete from entering your basement.

If your insulation contractor doesn't want to install closed-cell spray foam, it's time to seek out a different contractor.

Martin,

Thanks for explaining this in a way that is understandable. I appreciate all your articles and learn a ton from them.

Closed cell it is.

I'm insulating an above-grade 8" block wall in Virginia (climate zone 4.) I have a separate Q&A thread going (see link below) in which I am being counseled not to use foil-faced foam on the inside of my wall due to potential mold growth. I would like to use polyiso foam for higher R-value, but the polyiso available locally seems to have a foil face on it. Is there a reason above-ground concrete walls need to allow inward drying and below ground concrete walls don't?

If I do go with EPS and it is the lesser-quality type that is harder to tape, how about taping the seams with Zip tape, which is readily available locally, rather than European tape?

https://www.greenbuildingadvisor.com/question/is-interior-air-barrier-needed-with-tongue-and-groove-wood-wall-covering#comment-211273?utm_medium=email&utm_source=notification&utm_campaign=comment_notification&utm_content=view)

Timothy,

I disagree with the GBA reader who told you that foil-faced polyiso installed on the interior side of a CMU wall will lead to mold. (That said, you'll need to manage moisture on the exterior side of your wall with adequate roof overhangs and proper flashing -- but that is always the case, no matter what insulation you choose.)

I have never tested Zip tape on EPS, so I can't advise you on that issue. You're certainly right that foil-faced polyiso is easier to tape than unfaced EPS.

Dear Martin: I definitely respect your professional knowledge and building science credentials. That said, I have personally seen foil faced insulation lead to two instances of condensation and mold / water damage -- both in homes in the Northeast where humidity is an issue. One was an enclosed side porch with no HVAC, where so much condensation occured on the foil surface that the paint on the floor trim and the first couple of inches of exposed drywall were damaged. The second was in a basement in a home along the shore. During a major remodel, I entered the walk-out basement one morning and found a puddle of water under the vertically stacked panels of foil-faced polyiso foam board At first I thought there must have been a plumbing leak; there was that much water. But no pipes were located above the foam board. Then the reason became clear; the night before had been very humid with temps around 70 degrees. No HVAC was running. Windows were open to cool the house. The dew point was nearly 70 as well The foil surface on the 2" thick polyiso was very insulated, and cooled below the dew point. Voila! A puddle of water. I wish I had taken a photo to prove what I saw.

If these spaces had been conditioned - which reduces humidity - condensation would not have occured. But a basement or exterior room where moisture is high and HVAC or a dehumidifier are not present or not typically running, is NOT a place for foil faced insulation of any kind -- based on my direct experience. Plus there are good alternatives, e.g. poly faced foam board -- including polyiso. There is no reason to use foil faced foam board in these situations, and clearly reasons not to.

Mark

Mark,

Many issues here. One of the main issues is that if you open the doors and windows in a walkout basement during hot, humid weather, the outdoor air is likely to find a cold surface -- and often the surface is cold enough for condensation. This fact is the basis for the move away from vented crawlspaces toward unvented crawlspaces. Inviting summer air into below-grade spaces is a recipe for problems. So don't do it.

Sometimes the cold surface is a water pipe. Sometimes, it's an air-conditioning duct. Sometimes, it's the concrete floor or concrete wall.

It's rarely foil-faced foam, for the simple reason that foam has R-value, and the surface of the foam shouldn't be as cold as the concrete behind it.

Mark,

"The dew point was nearly 70 as well The foil surface on the 2" thick polyiso was very insulated, and cooled below the dew point. Voila!"

I'm having trouble with the logic of this. How does being insulated lead to cooling?

More pointedly, if the foam wasn't even installed, it has nothing to do with the reason some people are advising against foil facers on interior basement walls. It's simply a permeability issue, preventing drying where some suggest it's needed (whereas Martin and some others suggest drying in that direction is not needed).

Thanks, Martin. Regarding the exterior moisture management, here's a bit more context: This is a renovation of an existing garage, turning it into conditioned living space. The garage has no overhangs whatsoever and has painted stucco on the outside (photo attached.) Originally the homeowners wanted to put up vertical siding which would have allowed for a vented rainscreen to help keep the stucco dry. They have changed their minds and now want to leave the painted stucco exposed. Does this now mean that I should go with the more vapor-permeable EPS foam since there may be sun-driven moisture coming through the block? Any recommendations for a water-repelling yet vapor permeable paint to put on the outside of the stucco?

Tim,

You mention "moisture coming through the block," so this sounds like a garage with concrete block walls faced with stucco. In a garage, there really shouldn't be any concerns about possible inward solar vapor drive. But once you decide to convert the garage into finished space, inward solar vapor drive becomes a concern.

To reduce problems arising from inward solar vapor drive, you don't want to invite moisture into your home's interior. So your logic -- calling for EPS because EPS is vapor-permeable -- is wrong. The opposite tactic is called for: you want to exclude exterior moisture by installing foil-faced foam (for example, polyisocyanurate) on the interior.

That said, EPS wouldn't allow much vapor to enter, so this isn't a huge concern. Almost any type of rigid foam on the interior (including EPS) would be adequate to avoid inward solar vapor drive problems. The only reason I mention that foil-faced polyiso is preferable to EPS is to help you understand the basic principle: to avoid problems with inward solar vapor drive, you want to stop the moisture's travel inward rather than encourage it.

Of course, you need to pay attention to basic water-management details on the exterior of any building. All windows need to be properly flashed. Evidence of water entry after a rainstorm is always a red flag, and this type of water entry must absolutely be addressed before installing insulation.

Thanks, Martin, for the followup response. You are correct that the space is currently a garage built with concrete block walls faced with stucco. I will definitely do proper flashing and address any places where water may come in from rain. Once that is taken care of, is there a particular type of paint I should use on the stucco to prevent inward vapor drive? Am I correct in my understanding that in climate zone 4, with 2" of rigid foam installed on the inside of the block and all foam joints sealed properly with tape and canned foam, there is no concern for condensation on either face of the foam from inward or outward vapor drive?

Tim,

Q. "Is there a particular type of paint I should use on the stucco to prevent inward vapor drive?"

A. I don't think you have to worry about inward vapor drive (assuming you will be installing a continuous layer of interior rigid foam).

I'm not an expert on stucco paints, since there isn't much stucco in my corner of the country. For advice on selecting a stucco paint, I suggest that you post a question on GBA's question-and-answer page, where more readers will see your question.

Q. "Am I correct in my understanding that in climate zone 4, with 2 inches of rigid foam installed on the inside of the block and all foam joints sealed properly with tape and canned foam, there is no concern for condensation on either face of the foam from inward or outward vapor drive?"

A. That's correct.

In my basement, we built a stud wall and had closed cell spray foam installed behind the stud wall and partially into the bays. The plan was to then fill the rest of the bays with rockwool to get up above R40 since some of the walls were partially above grade.

We spaced the stud wall away from the foundation walls enough so that the foam was only supposed to encroach into the bays about a half inch, but I guess they sent an inexperienced spray foam crew and the depths were all over the place. We ended up using a long saw to slice the excess rockwool off just proud of the studs. It was a messy, time consuming, and wasteful job and I slap my forehead every time I think about why I chose to do it that way...Still the warmest area of the house by far though.

If I ever have to do it again, I'll go with rigid foam on the foundation walls and spray foam in the rim joist area where it's harder to get reliable and durable air sealing with a cut and cobble approach.

>"...I guess they sent an inexperienced spray foam crew and the depths were all over the place. We ended up using a long saw to slice the excess rockwool off just proud of the studs."

Even the Michaelangelo of spray foam installers can't deliver truly consistent depths and clean flat surfaces to mate with the batts. All "flash & batt" approaches have this flaw, whereas "flash & fill" (with blown fiber insulation) ends up nearly perfect with a lot less detailing labor involved.

Old house in building zone 7 with cement block basement. Was thinking of doing the continuous layer of EPS on interior with possibly comfortboard 80 to cover it for fire protection then galvanized steel studs. My question is is would it be worth covering the exposed exterior 12-18" of cement block above grade plus addition foot down with some form of insulation so that that the cement blocks aren't sitting at ambient temperature (which can be -40F)? Was not sure if having that upper part of the wall sandwiched between exterior and interior insulation was good idea or if that concern could be alleviated by using vapor permeable insulation on the outside somehow? Would also help with wind driven rain hitting that exterior exposed cement block.

For assembly #1:

1. Does it need a sill sealer under the EPS or is that redundant?

2. Should the EPS be sealed to the slab with caulk or something? I don't currently have any water infiltration issues but what will happen if there is a minor leak/flood in the future and everything is sealed up?

Dear Martin: Yes, of course, if you open the windows in the evening -- moist evening air comes in. But many people doe this around the country, not only in the Northeast, to reduce HVAC costs. So the same problem with condensation on a foil surface could occur.

My other example was a standard 2x4 studded enclosed wall around an exterior porch, with plywood sheathing and Tyvek on the exterior under new siding. Foil faced insulation was installed in the stud bays inside. The space was not conditioned. As noted in my previous post, condensation damaged the floor trim and drywall.

If you do a Google Scholar search, you will find lots of studies of "dew collection" devices based on the same principle. The dew on your car in the morning is another perfect example.

In short, why take the chance if you live in an area with high humidity? Poly faced or unfaced foam board is readily available Foil faced foam board delivers no appreciable benefit for indoor wall installations.

Mark

Mark,

The situations of above grade exterior walls and those in basements aren't at all analogous. It's not a good idea to take lessons from what happens on one and apply it to the other.

Mark, your words seem to imply that foil facers are some sort of condensation magnet. You discuss dew collectors and allude to a principle, yet it's unclear what principle (beside the phenomena of condensation itself) you are alluding to.

Dew on a car in the morning is caused by the surface of the car being below the dewpoint of the air, and it often becomes such due to radiative cooling.

I'm not saying to go throw foil faced polyiso into assemblies without knowing what you're doing, but its worth recognizing that the principles that govern whether a wall system is successful goes beyond 'foil causes condensation.'

Mark,

You wrote, "Yes, of course, if you open the windows in the evening -- moist evening air comes in. But many people do this around the country, not only in the Northeast, to reduce HVAC costs. So the same problem with condensation on a foil surface could occur. "

Just because people do this, doesn't mean they should. But the basic problem with your latest comment is the statement that a "problem with condensation on a foil surface could occur."

What you meant to write, I'm sure, is that a "problem with condensation on a cold surface could occur." Condensation will occur on any surface that is below the dew point, and the typical surfaces where this type of condensation usually occurs do not include foil-faced foam. If the cold surface is porous, like wood, what you get is moisture accumulation, otherwise known as sorption. But whether we're talking about condensation or sorption, you end up with more water -- either on or in the cold material.

If you have a cold concrete wall, you'll get both sorption and condensation under humid conditions. If you cover the wall with properly specified foil-faced foam, the interior foil facing will be warmer than the concrete (because the foam has R-value), and therefore the foil will be less likely to be a condensing surface than the uninsulated concrete.

The framing is up and 2.5" (R17 per contractor) of closed cell sprayfoam insulation has been applied to concrete walls and to the rim joists. (note rims already had, in theory, 2" of spray foam) We are in Zone 5a. In each of the two rooms there is a gap between the sprayfoam and the inside edge of the 2 x4 walls. Room 1 will be a a quasi theatre. Room 1 gap is about 2.5-3" and the wall is around 10' ft long. Room 2 will be game/recreation room . Room 2 gap is about 4", the wall is 24' long. Both Walls will have in-wall speakers in them. (Sound system will be bottom of the 2nd tier.) My plan is to install rockwool in the walls both to add insulation and to help with sound. This will covered by 5/8 blueboard and be plastered.

For HVAC, I have an ERV that draws air from between the two room and pushes it into the bigger room. In addition, once plaster goes up, two mini splits will be installed.

I am considering 4 choices for each wall.

Choice 1 - Install R-15 rockwood between the studs, leaving the substantial air gaps between the studs and the insulation.

Choice 2 - Install the rockwool between the studs and the wall. To keep the rockwool in place, I am pretty sure I need to step up a level or two in the rockwool thickness for Room 2. For room 1, I think can just wedge the R-15 in there.

Choice 3- Combine Choice 1 and Choice 2 by filling the void with rockwool and filling the stud bays with R-15.

Choice 4- Do nothing. Technically I meet code. Hope there is no wall echo/reverberations.

The choices do not have to be the same for both walls. The sound requirements for Room 1, which will also have a woofer and a surround sound system, may have additional sound issues to consider beyond just the in wall speakers. Room 2 will just have the two in walls. Except for the differences in the gap sizes and the length of walls, the moisture and insulation issues for both walls are equivalent - though the cost is not.

My primary concern is moisture/mold. Does the air gap between the two insulations create a moisture trap, pushing me toward Choice 2, if not Choice 3? Will Choice 2 have issues keeping the insulation in place? Is Choice 4 optimal as there is plenty of space for air to circulate and no insulation to trap any moisture?

My secondary concern is the risk that I finish the walls, install surround sound in Room 1 and Stereo in Room 2 and discover an echo/sound reverberations in the wall. Does Choice 1 create a echo chamber or does the rockwool between the studs mitigate it sufficiently? Does Choice 4 have potential echo chamber issues?

Of course I am concerned about insulation levels as well, but it is a basement and all but about 6" is below grade. Adding R-15 seems more than sufficient, but then adding an any fibrous insulation below grade has risks - even rockwood and even with the closed cell spray foam.

If moisture issues are roughly the same between Choice 1 and Choice 2 and I stuck with Choice 1, I could build some sound containment around the areas where the speakers are going to go. This is also an option for Choice 4

Lots to digest and keep going in circles. Any suggestions that would help me narrow down my choices would be greatly appreciated.

Thanks

-Bill

Hello,

I am in Zone 2 and bought an old ('68) split-level with a partly below-grade lower floor with cmu walls that is a walk-out on the back... would these assemblies apply in my zone/situation?

Thanks,

Trevor

Thanks for another informative article, Martin! I'm building a house in Maine next year and my basement plan looks like assembly #1 in this article.

Quick question: code requires new construction basement walls to be insulated, but I've read many times that one should wait at least a full year before finishing a basement. Does this mean I should wait a year before adding rigid foam to my interior basement walls? Or just wait a year before adding the 2x4 stud walls and drywall?

I'm also wondering: would it be reasonable to insulate the exterior of the basement with mineral wool board, and then add interior insulation and 2x4 walls several years later? I've attached an example from 475 building supply which has a lot more info than you need, but hopefully helps illustrate what I'm saying.

Thank you!

Michaela

Log in or become a member to post a comment.

Sign up Log in