The house that Dennis Miller plans on building next spring will include a cathedral ceiling with timber trusses exposed on the interior. The issue, as Miller explains in this Q&A post, is making sure the ceiling gets an effective air barrier that will prevent moisture problems in the roof.

“In a regular ceiling I’d think a continuous plane of drywall would do the job,” Miller writes. “However, this is a cathedral ceiling built on timber kingpost trusses that are exposed to the interior. In this case, the ceiling drywall is not continuous but broken into sections by the exposed timbers.”

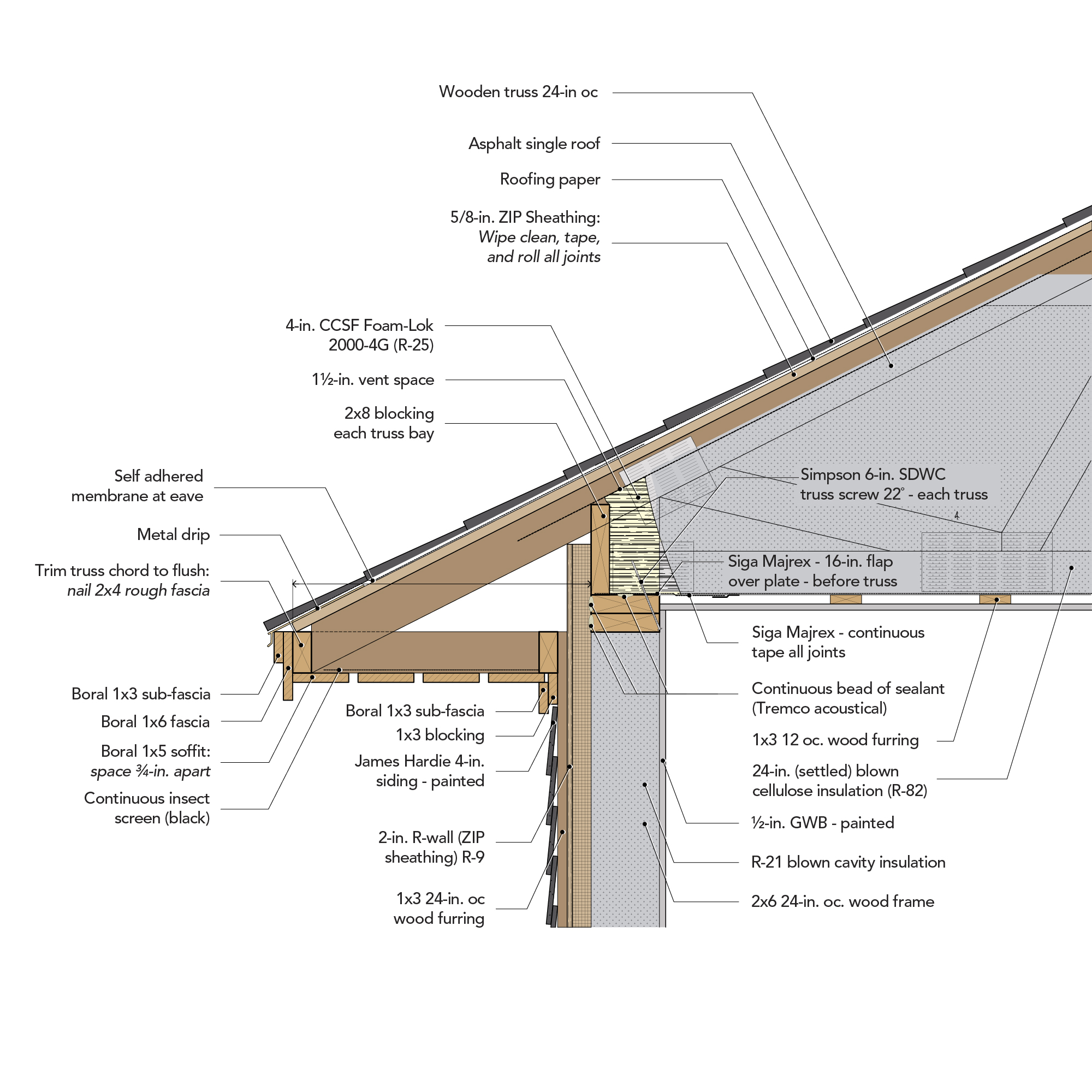

As the drawing at the top of this column shows, the ceiling will be insulated with cellulose. Rafters in this Climate Zone 5 house will be supported by a ridge beam and the outer wall in this double-stud wall design.

Miller wonders whether his only option is to do a “tedious caulking-gluing-sealing job” where the drywall meets the trusses. Or is there another way?

“I think my question really applies to any situation where someone has a ceiling with exposed beams,” he says. “What are some good methods to ensure a good air barrier when the ceiling plane is segmented?”

That’s the topic for this Q&A Spotlight.

A continuous layer above would be best

In general, Malcolm Taylor replies, the best approach is to include a continuous layer of material above the exposed trusses. “That’s in part why many timber-frame houses have tongue-and-groove or plywood roof decking, which can be fastened to the tops of the trusses,” he says.

Taylor thinks that sheathing and taping the tops of the 2×4 strapping would be the safest and most effective approach. As an alternative, Miller could use rigid foam insulation for that layer, although it isn’t…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

102 Comments

The whole process of framing on top of a structural timber frame just for blown cellulose seems a bit much when SIPs panels can be installed much quicker and as a continuous insulation with a cold roof system.

If you are willing to take the chance that the panels will be properly sealed, including where they sit directly and inaccessibly on the underlying timber-frame. SIPS for some of us still represent an unacceptably high-risk assembly

I agree. I built my home with a Great room last year and used SIP's for my ceiling insulation solution and structural help. Timber Trusses along WITH a ridge beam, is that necessary with a SIP? I did not use one. I have huge timber trusses on a 12:10 SIP panel roof. Remember there are structural benefits to using SIPS. Not just an insulation innovation!

After flying in the trusses we placed one entire side of the roof in one lift with a crane. It was in one piece and already tape sealed. With electrical chases already in the 12" thick foam installing lighting was simple too. THIS is the way to go. The old ways are simply outmoded by SIPs.

We've completed an insulated timber framed ceiling in a home using RockWool batts for a client who did not want to use foam. It was a multi-layered assembly (2x6 Vgroove ceiling, breathable membrane, TJI's with Rockwool, taped sheathing, 2x4 vent channel & roof sheathing) that worked well, but had to be done from the outside. Unfortunately we had scheduled the work for August which is normally hot and dry, but the constant and nearly continuous rainstorms forced us to postpone the work until late fall. Our primary air barrier was taped sheathing which formed the bottom layer of our continuous vent channel above the insulation. Lesson learned: don't rely on the weather.

I had this same situation with cathedral ceilings and timber frame.

On top of the exposed timber frame rafters we placed 1 x 4 strapping. Then constructed the roof cavity on top with conventional 12 inch TJI. The strapping gave enough space that we could go in with 5/8 tongue and groove, slip the tongue and groove on top of the rafters and nail everything to the bottom of the TJI.

For insulation, I wanted definitely to air seal and after looking at alternatives - chose to spray the roof cavity with 9 inches of closed cell insulation. So I ended up with a roof at R-63 that was airtight and still had a 3 inch gap on top of the insulation for a vented roof assembly. Aesthetically, tounge and groove looks much nicer than drywall. Great contrast to the timbers.

You will also need your electrician to place any required ceiling lighting prior to spraying with closed cell. For ceiling fixtures, I went with surface mount LED that gives off very little heat as the cans are embedded in closed cell.

“[Deleted]”

Dennis Miller appreciates all the ideas and comments. I would comment that I'm not a total newbie to air barriers. We designed and built a passive solar timber frame back in 1984. Several things we did that almost no one else was doing at that time was (1) 2x6 walls (between timbers), (2) masonry chimney interior to house rather than on exterior wall, and (3) we used this stuff almost no one had heard of called Tyvek, (4) the exterior walls had an external layer of XPS (almost no thermal bridges), and (5) even the basement walls had 2" exterior XPS. I look back and think we did pretty good for 1984. But now it's 3 decades later and we want even more for what we assume will be our retirement home.

I like Peter Yost's terminology that we want to use both physics and chemistry to get best results. So I'm trying to corroborate everything I've read on GBA and I still have questions. For example, one question is about Peter's statement #3 that air-permeable insulation should be confined on all 6 sides (by an air-barrier?). But what about an attic floor buried in a blanket of cellulose? I'm not aware of anyone covering the top of attic cellulose with an air barrier. Is this an exception, and if so, why?

> covering the top of attic cellulose with an air barrier

Or even fiberglass on an attic floor.

More airflow to/from the exterior than to/from the interior has a drying effect in Winter (ie, is OK). In summer (with AC), it could be an issue. A good air barrier on all six sides always blocks wetting from air movement.

Dennis,

Q. "What about an attic floor buried in a blanket of cellulose? I'm not aware of anyone covering the top of attic cellulose with an air barrier. Is this an exception, and if so, why?"

A. A layer of Tyvek on top of the cellulose on your attic floor might be a good idea, but it's expensive and tricky to install well. It's far cheaper to just blow more cellulose on top of the existing -- deeper cellulose has the same thermal benefits that a layer of Tyvek might provide, at a fraction of the cost. So codes don't require a layer of Tyvek -- it wouldn't be cost-effective. If you want better cellulose performance, just keep piling it deeper.

what thermal benefits does "Tyvek" have? It has no R-value or thermal mass. Besides cellulose manufacturers recommend not using a vapor barrier. Are they wrong?

Another question I have -- GBA has convinced me that vapor diffusion is usually a trivial problem, that the real issue is infiltration/exfiltration. I'm definitely concerned about dealing with warm interior air leaking into walls/ceilings where the "winter design temperature" is 10F (-12C). So it seems I'd want an air barrier to prevent this exfiltration, right? And the 2nd half of the question, should I be concerned about the reverse, the infiltration of warm moist summer air when the interior is being air conditioned? I'm not in the deep south so I could believe an argument that PA climate has limited amount of time where condensation could occur and plenty of drying out time as long as walls/ceilings don't trap moisture. Would a single air barrier somewhere to the exterior be adequate for both cases? And should I make my wall able to dry to both interior and exterior?

Vapor diffusion can be an issue, which is why code covers the issue of what class vapor retarder can be used where (in walls).

Instead of just infiltration/exfiltration, think about any type of air movement.

> should I make my wall able to dry to both interior and exterior?

That is one way to make a good partition. There are other ways that only involve drying in one (or no) direction.

Joe Lsiburek showed that 97% of vapor flow through walls travels on air. Stopping air movement stops vapor flow, which is why getting the house air tight is so important.

The walls need to be able to dry to the interior, or to the exterior or both. Our double stud walls, for instance, are vapor permeable both ways, and basically air tight.

Bob Irving, you described your ceiling structure earlier and I think I understand that, sheathing above your TJIs formed the air barrier and after a ventilation space, a layer of sheathing above that was your roof deck. I'm curious what was your double wall structure, and also what is your location. Your description of a wet summer sounds a lot like we experienced this last summer.

To those who like SIPs, seems to me they certainly have their advantages. They are not the most budget-friendly however which leads to considering other options. Also I do not see this as a lot of extra structural work. In building an exposed timber flat-ceiling room with an uninhabited attic overhead, one usually has some kind of ceiling joists above the timbers plus rafters and ridge board (or beam). So I do not see this cathedral ceiling structure being much different than a typical flat ceiling structure or a outdoor deck for that matter.

Joe Lsiburek fails to factor in which insulation is being used. Cellulose stops air flow, therefore most moisture. Any small amount is breathed just as 2x4's change moisture content.

Cellulose doesn't completely stop air flow, though it's fairly air retardent, particularly a dense packing densities. At 3.5lbs cellulose is about as air retardent as 1.8lbs fiberglass (common dense-packing densities for either.) At 2.2lbs fiberglass is more air retardent than 4lb cellulose.

At 1.5lbs (open blown) density cellulose is still fairly air retardent, whereas at 1lb & lower fiberglass is not.

Lstiburek and the people at Building Science Corporation actually test & measure stuff (often, and in many ways, often paid by the D.O.E. to do it), including moisture migration in dense packed insulation. You can count on Lstiburek being on fairly solid ground regarding this one.

Jon, my take from GBA (and Building Science Corp) is that vapor diffusion is trivial, at least from the interior, that the thing to go after is the air leaks (exfiltration/infiltration). So other than vapor diffusion and air leakage, what other air movement is there? My understanding from GBA or guys like Lstiburek is that the code requirements for vapor barriers are mostly wrong-headed. So I think my confusion factor just went up!

There is also air that moves from the interior, deposits moisture and returns to the interior.

Poor air sealing would make make vapor diffusion trivial - but you aren't going to do that, right? Lstiburek doesn't think vapor diffusion is important? "perm" occurs 76 times in below! It also lists recommendations, so one can usually pick one without worrying about theory.

https://buildingscience.com/documents/digests/bsd-106-understanding-vapor-barriers

Dennis,

You might want to read this article: "The Return of the Vapor Diffusion Bogeyman."

Martin, I've read that "Bogeyman" article at least a couple times already and I'm not sure what I'm missing. The article says diffusion is not a big problem except in cases like high humidity rooms or reservoir siding, etc. You recently added one more scenario, concern about vapor diffusion affecting exterior sheathing in double-stud walls in cold climates, which is my scenario. So I'm thinking I should be concerned about diffusion and intended to follow a couple suggestions in the article of using plywood sheathing and vinyl siding as a ventilated cladding to help with durability and drying to the exterior. On the other hand you recently commented to me at the end of the article "Choosing a Cost-Effective Wall System" that "Vapor diffusion is way down toward the bottom of any list of concerns. So here's my advice: Pay attention to airtightness, and stop worrying about diffusion." It seems to me that these comments must be addressing different scenarios because they otherwise seem contradictory to my mind. Can you clear up my confusion?

Jon, I did not mean to say that air diffusion was never important, just that I've been under the impression they were trivial in my case since I don't have reservoir siding or high humidity rooms and such. I believe all of the walls illustrated in the bsd-106 article either contain brick, block, concrete or stucco, none of which I have in my wall. But I'm pretty sure I've read articles both from GBA and BSC downplaying concern about diffusion in a well-constructed stud wall and giving infiltration much higher priority. But I could be wrong and am ever grateful for any enlightenment.

I have no cognitive dissonance with comments of the form "A is much more important than B, but both are important".

Lack of reservoir siding will make Lstiburek's recommendations even safer.

Jon,

Would it be fair to say that in the absence of reservoir cladding and a hot, humid climate, diffusion can safely be disregarded as long as the permeability of the exterior surfaces exceeds that of the interior?

.1 perms on the interior and .2 perms on the exterior would suffer from a lack of diffusion/drying. And then there is code compliance - which forces attention to perms/diffusion and doesn't allow vapor retarders based on ext > int.

Dennis,

You're on the right track to design a good wall, and I think you have your priorities right. Dan Kolbert, a Maine builder who sometimes posts comments on GBA, refers to moisture problems in double-stud wall sheathing as "the yeti of building science" -- much discussed and never seen.

If you follow GBA advice on double-stud wall details, there is no reason to believe that your wall can't handle any vapor diffusion issues.

Dense Pack cellulose doesn't need an air barrier in rafters. Just as in walls, cellulose, unlike fiberglass, is packed tightly so there is no air circulating or leaking. No air means no water dropping out...means no moisture or mold. Fiberglass insulates by the air between the glass strands. Fiberglass is mostly air. It needs an air barrier and must be shielded to prevent human exposure. This is overkill based on poor understanding of cellulose. Fix fiberglass with a vent channel, not cellulose.

Larry,

If you are putting cellulose between rafters -- an approach that is only legal when either (a) there is a vented air space between the top of the cellulose and the underside of the roof sheathing, or (b) there is an adequately thick layer of rigid foam above the roof sheathing, or (c) there is an adequately thick layer of closed-cell spray foam between the top of the cellulose and the underside of the roof sheathing (the "flash-and-fill" approach) -- you certainly need to pay attention to air barriers on all sides of the insulation.

The usual way this is accomplished (in scenario "a") is to make sure that the ventilation baffles are installed in an airtight manner.

Martin, please cite the law requiring this. Countless cathedral ceilings and walls are densely packed with cellulose annually to compensate for poor performance from fiberglass. Homes could not be retrofitted with upgrade insulation otherwise. And while you are at it, where are the "studies" supporting your claim about a "foam layer" above the cellulose? And your article makes no mention of any testing of foam's ability to not degrade, lose R-value, or structural integrity. "Foam" varies in formulation almost as much as the producers selling it. Your claims deter homeowners from retrofitting optimally. And there's no such thing as an "air barrier on all sides of cellulose." If that were possible it would be an "air leak" not an air barrier.

Larry,

Q. "Please cite the law requiring this."

A. The International Residential Code sections R806.1, R806.3, and R806.5.

For a full explanation of these requirements, see my article, "How to Build an Insulated Cathedral Ceiling."

Q. "While you are at it, where are the 'studies' supporting your claim about a 'foam layer' above the cellulose?"

A. I never mentioned studies, but I am happy to provide links. Here are two online references:

"Exterior Rigid Insulation Best Practices"

"An Exploration of Exterior Insulation Strategies for 1½-Story Roof Applications in Cold Climates"

GBA has lots of articles on this topic. Here is a link to one of the articles: "How to Install Rigid Foam On Top of Roof Sheathing."

Q. "And there's no such thing as an 'air barrier on all sides of cellulose.' If that were possible it would be an 'air leak' not an air barrier."

A. Dense-packed cellulose is not an air barrier. ASTM E 283 defines an air barrier as a material having a maximum allowable air leakage rate of 0.02 liters/second/square meter at 75 Pascals pressure difference, and cellulose insulation, dense packed or not, does not meet the standard.

As Joe Lstiburek has written, "Dense pack cellulose and dense pack fiberglass are not air barrier materials, and they do not result in air barrier assemblies. Although, with respect to air barrier assemblies, they sometimes come pretty close."

Martin, the cellulose system does not need an air barrier. It blocks most air and at the same time "breaths." Keep in mind that foam, fiberglass, and cellulose are three different products, each relying on different technology. You can't fix the problems of foam with fiberglass. Likewise, just because fiberglass is incapable of blocking air flow, don't force that weakness on foam or cellulose. Fiberglass is incomplete without a vapor retarder. Cellulose doesn't need one. I suppose if lobbyists press hard enough the standards folks can force one-size fits all mentality. That's government at its worst. Again, local building codes prevail. Even then, contractors can be forced to do this or that task simply because the local inspector reads generalized "best practices" about vapor barriers and therefore forces work not needed. That mentality sells a product but doesn't serve the homeowner or our ecology.

Larry,

Q. "Fiberglass is incomplete without a vapor retarder. Cellulose doesn't need one."

A. You're wrong. Building codes require cellulose-insulated walls in Climate Zones 5 through 8 to have an interior vapor retarder. Researchers have expressed concern about vapor diffusion issues in cold-climate walls insulated with cellulose. For more information, see "The Return of the Vapor Diffusion Bogeyman."

No, I'm not wrong. Fiberglass without vapor barrier LEAKS air like a furnace filter leaks air. Why burden cellulose with the shortcomings of blown/batt fiberglass?

Again Martin, you are citing the International building code. I guarantee my local inspector has not read it nor even has a copy. I know your citation helps scare folks into extra work and extra material costs but one-size does not fit all and foam is harming our ecology and is not cost-effective. What incentive is there in "curing" a problem that does not exist when using cellulose. Show me a research study with cellulose failing to stop air infiltration/moisture. And just for giggles build three houses, foam, fiberglass, and cellulose and measure the heat load on each. Then set all three on fire and time their respective incineration. And maybe while they are burning measure the deadly off-gassing from foam..and even the gasses from melting fiberglass. That's a study your readers would enjoy reading/seeing. Instead, you keep posting an opinion. Do a genuine study.

Thousands of older homes in the USA are retrofitted with cellulose in the walls. Other's get retrofitted with pump (water) foam, even more, get blown fiberglass. Most of this work is done on existing, therefore "closed" walls. None have existing vapor barriers. None get vapor barriers added. Most often the retrofit work does not require code inspection (although some do when the walls are opened.)

Martin, again, I'm embarrassed for you. What does a story about rigid foam shrinkage have to do with anything? To repeat, each foam from each manufacturer is a different formulation. Some shrink (badly), some burn (badly), some lose R-value (badly), and some deteriorate over time (badly). Ridgid foam is cured in the factory. I'd be surprised if ti shrank. The spray foam placed in your new home is more likely to fail one (or more) of the above criteria. Pump foam is especially vulnerable to shrinkage. It cures in an enclosed wall, out of sight so no one really knows until an infrared camera is used to expose the shrinkage problem.

I understand a spray foam company's decision to promote less spray foam thickness on walls. Spray foam, when sprayed to quickly, too thick, can't cure correctly. The gasses are "trapped" inside the thickness of it all so never dries. As a result, it is subject to "off-gassing forever (it seems). The gasses are deadly. Even if the off-gassing doesn't kill, in the event of a fire, the gas released from burning foam is more likely to kill occupants than the smoke or fire of normal combustion. By spraying the foam thin it can cure and not create that legal liability...and it's more profitable using much less material. Homeowners, like yourself, believe it's Premium" and even gladly pay to compensate for missing foam by filling the wall cavity with inferior fiberglass. So a lose-lose scenario is promoted as win-win. The foam formulator doesn't get sued and the homeowner can brag they have expensive foam insulation and claim it's the foam that tightens the house, not the wrap. Wonderful stories can be written about the experience. Oh my!

Seriously? The local building code governs what is required locally! Try telling the local inspector she's wrong by citing your "International code." Besides, even the code you cited calls for a maximum of 1/4" air space which doesn't warrant filling the cavity with over-priced under-tested foam. Can you even cite such a requirement in the (USA) "National Building Code", which some local jurisdictions follow?

Your specified code does not require an air ventilation space in cold areas providing a vapor barrier is used...which is standard in the USA.

Tell me, has anyone in Europe even heard of cellulose insulation? After all, they build stone walls, typically.

You know, on a side note, "internationally" many laws/regulations exist that aren't applicable to the USA. For example, food ingredients and drugs are often "approved" or alternately, "not allowed," contrary to USA regulations. The USA almost uniquely builds using the platform method. Stone is used in Europe. While in Africa I lived in a very comfortable grass hut.

Seriously? You refer me to your articles as "studies?" Seriously? Articles are stories. As I said, there are no studies. And you failed to defend foams shrinkage, deterioration, and reduced R-value after curing and over time. Not to mention the harm foam does to our environment. Don't you feel any societal responsibility?

Moisture moves by two transport mechanism: air movement and diffusion. Air movement accounts for 98% of moisture problems. Cellulose manages moisture.

"Joe Lstiburek" might want to read the position of the Cellulose Insulation Manufacturer's Association's position on air barriers. Does he know better? They clearly oppose them with cellulose. And please stop grouping cellulose with fiberglass. Fiberglass needs all the help it can get, including air barriers and a nice coating of cellulose on top to stop air leakage through the fiberglass.

https://www.cellulose.org/HomeOwners/AirVaporBarriers.php

So Larry, What does your "local" code say about ventilated roofs?

Malcolm, want to define YOUR UNDERSTANDING of a "ventilated roof?"

Larry, your post appears to have lots of it paraphrasing from the CIMA group link you offer-- a group of common interest manufacturers hoping to offer consumer marketing to sell more cellulose. Seriously?

It appears you strongly believe "foam" is overpriced and under tested. Well, I just built my home last year and used 3" of foam over the ceiling rock and all penetrations. Finished off with 15" of that also-reviled blown in fiberglas. THIS is a very tight home. Without using foam it is nearly impossible to even come close, period. Run a blower door test on a cellulose only insulated home-- with NO foam. You will see.

NOTE: Here in cold Minnesota the International building code has been adopted by the state, which also means LOCAL if adopted by local ordinance.

Perhaps with more reading on GBA you will notice, like myself and many other contributors, that the breadth of knowledge is deep and based on real studies in both academia and government agencies. Folks here and in Europe are attempting to communicate the present state-of-the-art and leading edge-- not the status quo. Sometimes there are no studies yet but folks are offer alternatives through their experience for the benefit of the rest. No one is saying there is only one correct way; often GBA contributors offer multiple routes.

CIMA has done studies. So have others. Oakridge Laboratories has some great studies showing how fiberglass loses half its R-value in cold weather. Why not include them in your stories? Instead, you dominate with the marketing of stories promoting over-priced foam.

>"Oakridge Laboratories has some great studies showing how fiberglass loses half its R-value in cold weather."

Really?

Point me to one of those studies!

With air barriers on all sides fiberglass (even low density fiberglass) INCREASES in R value with increasing temperature difference across the layer.

Dana, contact Oakridge Laboratories and ask for it. Or visit the CEMA site. They used to reference it in one of their articles. They also have a research document comparing two identical buildings, one of cellulose and one of fiberglass. The cellulose insulated building was 30% more energy efficient even though the building was 17% draftier prior to insulating with cellulose. Pretty remarkable!

Show me the test results from your blower door tests on a "cellulose only" home. While you are at it where's the blower door tests on a "fiberglass only home." In fact, do two one with a vapor barrier and one without. And do one on foam only too! In fact, you set it up and I'll insulate the cellulose home.

I'm curious, have you tested your home since the foam aged?

Frankly, with the advent of really great vapor barriers and the practice of air sealing all wall penetrations, you can only seal so much. Once it's sealed it's sealed, regardless of chosen thermal insulation.

CIMA manufactures have done some great research studies, some in conjunction with Oakridge Laboratories. You do understand Oakridge developed the trigger for the atom bomb ending WWII? A government research facility, they are above reproach and have done extensive research with cellulose and "air sealing". Again, what is the source of your funding, Martin?

Larry,

Q. "What is the source of your funding, Martin?"

A. I am a journalist. I am a full-time employee of Green Building Advisor, which is published by the Taunton Press. I have a salary -- one that reflects what journalists make these days. I'm not on the take.

I'm also a big fan of cellulose insulation, which you would know if you read more GBA articles. See, for example, "How to Insulate an Attic Floor", in which I wrote, "There are three common types of insulation used to insulate attic floors: fiberglass batts, blown-in fiberglass, and cellulose. Cellulose is the best choice."

Marten, I'm not a "fan" of cellulose. I simply recognize the benefits compared to other products. If fiberglass or foam did the trick one of those would be my choice.

No thanks, I don't need to read your opinions on cellulose as floor insulation.

Martin, I took a moment to read your floor insulation article, the one you suggested I read. Taunton Press blocked my visit. They want me to pay a fee to read it. That's another source of income you did not consider, Tauton uses your stories to entice readers to buy a "membership." LOL, if I want to read an article about insulating floors with cellulose I'll write one. And for the record, I'd let you read it without charge.

Lots of folks know foam is over-priced. But be honest, Martin, "Foam" is formulated many ways so each has unique characteristics. All are harmful to our ecology. All are over-priced compared to better solutions. You had to pay for two insulation technologies to do a simple job, stop air infiltration and reduce thermal loss. Where's the study showing how cost-effective your choices are? For example, a 96% efficiency furnace is 16% more efficient than the old 80 percenter it might replace. But how much money is saved? Is the savings worth the 5-10K investment?

Larry,

The International codes (International Residential Code, International Energy Conservation Code, etc.) are, for all intents and purposes, our national building code here in the U.S. Each state (with the exception of California) has adopted some version of these codes, with revisions in some cases.

You are absolutely right that individual code enforcement officials sometimes look the other way when it comes to code violations. Their interpretations have the force of law.

Q. "Tell me, has anyone in Europe even heard of cellulose insulation?"

A. Yes. Here is a relevant link from the U.K, which as of this morning is still part of Europe: Isocell Insulation.

Q. "You refer me to your articles as 'studies?' Seriously? Articles are stories. As I said, there are no studies."

A. Plenty of researchers have studied exterior insulation. The NREL report I linked to notes, "This exploratory study found that research favors an exterior approach to deep energy retrofits and ice dam prevention in existing homes using the external thermal moisture management system technique. ...Results from this research can help direct future Building America research activities in efforts to create information for professionals, homeowners, and insurance companies."

Q. "Joe Lstiburek might want to read the position of the Cellulose Insulation Manufacturer's Association's position on air barriers. Does he know better?"

A. That will be an interesting fight. My guess is, "Probably."

LOL, Martin, you are betting on a philosophy Ph.D.! At best a civil engineer. Do you really think he knows something about cellulose not already known? You folks are guilty of believing your own press.

Larry,

Joseph Lstiburek has a Bachelor of Applied Science from the University of Toronto;

Master of Engineering from the University of Toronto; and a

PhD in Building Science from the University of Toronto.

He's also an ASHRAE Fellow.

He knows more about cellulose insulation than most human beings. He has been deeply involved in insulation research for decades.

Be honest, Martin, he claims a Ph.D., in "Philosophy of Building Science." He councils abandoned houses on the verge of suicide...I think!

I am honest, Larry. Dr. Lstiburek has a PhD (sometimes referred to as a "doctor of philosophy degree") in building science from the University of Toronto. As the school's web site notes, "This program is designed for outstanding individuals interested in a rewarding career in fundamental or applied research. The Doctor of Philosophy program involves advanced courses and an intensive research program culminating in a thesis."

Concerning building science, the web site notes, "Building science is the study of building materials, components, details, and construction methods with respect to the maintenance of the required temperature and moisture conditions of the interior of buildings. Building science involves the understanding and application of fundamental concepts in physics, chemistry, and other branches of science to the problem of engineering effective, efficient, and economical building envelopes."

I couldn't find any references to the "psychology of building science"-- but maybe you could start a new program in that field at a U.S. university. The field of study might include a course or two in abnormal psychology, for instance.

Martin, could you (or he) direct me to his published work on cellulose insulation? From what he's demonstrated here it appears he's ignoring the science of cellulose. He degrades it by association with fiberglass. Is there a political or monetary motive behind that? Maybe he's just misinformed himself?

I really want to read what he "knows" about cellulose insulation. That's the one link you haven't provided. I have links to your many stories but nothing on cellulose research (except my own).

Larry,

1. "Don't Be Dense - Cellulose and Dense-Pack Insulation."

2. "The Thermal Metric Project."

Martin, you are side-stepping my point. What part of any code is adopted by whatever jurisdiction is anybody's guess? Maybe you want to cite the National (USA) building code instead of International?

"Ice dams" are caused by inadequate insulation. That typically translates to blown fiberglass allowing heat from ceiling drywall to conduct upwards and warm the 'glass and air above. That warmed air rises, warms the roof, and melts the snow laying on the shingles. That thin layer of water flows to the roof's edge and freezes. Over time icicles form. It's easily corrected by pulling (sweeping?) the fiberglass away from the eves at least one-foot and covering the ceiling edge (over the exterior wall's top plate with cellulose. The cellulose stops air infiltration and heat loss. It's a very nice, inexpensive fix for ice dams. Did I mention the ice dams occurred because the fiberglass doesn't stop heat loss from the living area? Maybe it's just me but it makes more sense to identify the root cause of ice dams and correct the original flaw. No need to re-invent the wheel so others can profit. Stop using inferior fiberglass and the building codes won't need to be so convoluted.

" . . . adopted by whatever jurisdiction is anybody's guess"

Larry, there is no guessing. Below is the STATUTE pointing out exactly what parts of the international code are adopted or revised here in Minnesota. Uh, almost ALL of it!

You can find YOUR level of adoption by going to your state statutes on line and find the same thing as shown here for Minnesota.

the link: https://www.revisor.mn.gov/rules/1305.0011/

Brian, "State Statute" isn't local. Local picks and chooses and otherwise creates what's best for local. I'm sure the politics is as involved at state, national, and international levels, which supports the reality one size doesn't fit all. Even then, two inspectors in the same town have different takes/understanding of both the local code and the circumstance it's being applied to. I suppose with stories placed for public consumption can sway opinions away from doing the practical, and instead, doing the expensive. I'm seeing foam advertisements all over my computer screen while reading GBA. Are you a public corporation fully exposing your sources of income?

Larry,

Q. "Are you a public corporation fully exposing your sources of income?"

A. Taunton Press is a privately held company. GBA gets most of its revenue from subscriptions, but a portion of our revenue definitely comes from ads. The ads you see on your screen probably reflect your own web viewing history, because every reader sees different ads. I strongly urge GBA readers to ignore the ads and read the articles.

At no time in my journalistic career have I ever changed an article due to pressure from advertisers. The day I am asked to do that will be the day I quit my job.

LOL. "Tauton Press." Thank you...LOL

Since Taunton Press is privately owned how would you know its sources of income? I'm familiar with your employer and doubt seriously most income is from subscriptions. Your magazines are full of advertising with very few articles. Taunton Press is a marketing company. It sells books. It has "special offers" weekly. In fact, I personally get the same Taunton Press magazine promotions for two different magazines. the promotions are identical except for two different magazines.

Larry,

Q. "Since Taunton Press is privately owned how would you know its sources of income?"

A. As editor of Green Building Advisor, I receive regular reports from the owners of the revenue streams that support GBA. As I said, significantly more than half of our income comes from subscriptions.

If you are a cynic, you may well wonder, "Why does Martin Holladay think that his employers are telling the truth? Maybe they are lying." If that's your world view, I would call it deeply cynical. I know that journalists are held in ill repute in the U.S., but in my experience -- believe it or not -- most journalists have a dedication to the truth.

Martin, it's referred to as a "doctor of philosophy degree" because that's what it is! YOU drop the "philosophy" part because, perhaps it doesn't carry the weight you think it should?

Seems like you need a history lesson. A long time ago, there was no such word as "science". Back then, what we would call a scientist today was called a "Natural Philosopher". That is the etymology of the term "doctor of philosophy". It's simply the designation for the highest academic accreditation you can obtain, in any field. Do you really think that after getting a Masters degree in something like mechanical engineering, you suddenly change gears from science based learning, to simply pondering things while smoking a pipe in a velour chair beside a fireplace? Is that what you imagine a PhD is?

The top people in EVERY field have PhDs. Some of those fields carry more weight than others. I personally am less impressed by someone with a PhD in sociology than someone with a PhD in theoretical physics, but that's just my opinion. But if someone has a PhD in building science, you can rest assured that guy knows a hell of a lot about building science, and next to nothing about what we colloquially think of as "philosophy".

Trevor, fairy tales begin with, "A long time ago...in a faraway land..."

You made my point, what is a philosophy degree in building science? Is that degree common in colleges? Or is this one of those degrees creates especially for the individual? There's a big difference between a doctorate in building science philosophy and a doctorate in thermodynamics.

Your effort at teaching "history" is meaningless. "Back then," isn't today. Today, much "research" is tainted. These folks need to sell stories,

If your opinion on the relative value of compared Ph.D., programs are based on academic requirements then your conclusion is supported by fact. There's a reason his Ph.D., bears a philosophy distinction rather than a science one.

Therein lies your dilemma. Lots of researchers seemingly "know" their topic, but skew the results. Sometimes the misrepresentation is based on fraud. Other times it reflects a lack of understanding. They set the experiment up wrong. Or make the wrong conclusion. "Building Science" as you all call it, is simple but made convoluted to warrant stories. Stories that sell information...magazines, books, videos, etc. Instead of being loyal to the science these readers are loyal to those feeding misinformation.

A Ph.D. in philosophy is not as demanding as one in engineering. It's a much easier route to buy credentials...used to assert authority. I prefer to look at the science and see what is there.

Larry,

You are fixated on the mistaken notion that engineers with PHD's have them in philosophy. That's factually incorrect. Get it? It's not something you can have an opinion on , it factually wrong.

I have a bachelor degree in architecture. That doesn't mean I'm not married.

is any of this sinking in?

Larry,

Q. " What part of any code is adopted by whatever jurisdiction is anybody's guess? Maybe you want to cite the National (USA) building code instead of International?"

A. No, it's not anybody's guess. It's well documented. Here is a link to the BCAP site which provides a map that shows code adoption progress: Code Status Maps.

There is no such thing as the "National (USA) building code." You just made that up.

Q. "Ice dams are caused by inadequate insulation."

A. Perhaps sometimes -- but that's actually quite rare. In the vast majority of cases, ice dams are caused by air leakage.

Martin, since you are dedicated to writing the "truth," any plans to write about foam shrinkage? Or maybe the damage foam manufacturing does to our ecology? Or foam's lack of cost-effectiveness. How do you rationalize that stiff price for thin spray foam only to also pay for loser fiberglass? Did someone do a masterful sales job on you, Martin? Please review your foam contract and tell us, is the foam guaranteed to not deteriorate as it ages? Or lose R-value as it ages? You see, the contractor covered his backside by adding fiberglass. If the foam disintegrates you'll never know because fiberglass is in place.

Larry,

For more on foam shrinkage, see this article: "Using Rigid Foam As a Water-Resistive Barrier." (Scroll down to the section that begins, "Do rigid foam panels shrink?")

For more on environmental damage caused by foam, see these articles:

Calculating the Global Warming Impact of Insulation"

"Insulation to Keep Us Warm — Not Warm the Planet"

"Avoiding the Global Warming Impact of Insulation"

For more information on cost-effectiveness, see "It’s OK to Skimp On Insulation, Icynene Says"

For more on the changes to rigid foam R-value due to aging, see "Thermal Drift of Polyiso and XPS"

Martin, "International Building Code" is a noun. It exists is SOME countries, not in most. The American code is as varied as the local jurisdictions are varied. I already said that. If I speak about Ameican code, USA code, "national code," what word do you prefer I use? All I can say is what I've already said, the local code rules, not state, not national, not international. And since your philosophy Ph.D has influenced the international code, it's convoluted and folks are forced to do standards that are not warranted by the science. The science of heat flow was decided long ago. It's called thermodynamics, not air flow. Does your friend have a philosophy degree in thermodynamics, too? I'm sure he's a great road builder but heat flow is not civil engineering.

Again, Martin, State code is not Local code. Local chooses for local conditions and needs and local folks even think and decide what's best for the community. Sometimes they get it right. Sometimes they get it wrong. But anyone having allegiance to the ramblings of a philosophy major on insulation technologies should be wary. Again, where is his research on the various insulations? Airflow studies are not insulation studies. Airflow research is not insulation research. What are you people doing here? What you have accomplished is the selling of magazines and the recruitment of laymen to parrot your philosophy of what you call "building science." What am I missing?

Martin, LISTEN CLOSELY, please, my term "inadequate insulation" is synonymous with your phrase "caused by air leakage". Air leaks from the ceiling can lights, fans, bathroom vents, holes drilled/cut for electrical wiring, plumbing vents, etc. Blown fiberglass FAILS to stop the air infiltration, therefore it "leaks air." To compound the problem, the fiberglass is thinner at the ceiling's edge so the warm drywall beneath warm the attic air above melting the roof snow. You know the rest. Martin, sometimes, talking points are not enough. You need to appreciate the differences between foam, fiberglass, and cellulose.

Larry,

You wrote, "Air leaks from the ceiling can lights, fans, bathroom vents, holes drilled/cut for electrical wiring, plumbing vents, etc." You're right on that point -- and on that point we agree.

You wrote, "You need to appreciate the differences between foam, fiberglass, and cellulose." If you take the time to read more articles on GBA (and dial back the condescension), you might realize that I do appreciate the differences.

Martin, I described the events leading up to ice dams. You totally ignore that and refer me to more of your stories. Why not accept my scenario (or reject it.) Then refer me to your stories if you offer an different causation. My solution is cheap and effective. But it doesn't lead to lengthy articles. It's just work.

Martin, if you UNDERSTOOD the difference you wouldn't push foam so hard.

Let's just take a moment and appreciate the remarkable patience Martin has and the dedication to providing thoughtful and well researched answers to all who seek, even those who have an attitude that resembles that of a mythical bridge underbelly dweller. Thanks to you and your team for the great work!

Yupster,

Martin must have the patience of Job. Its one thing to argue with people holding reasonable opposite views, it's another to respond to belligerent ignorance.

Look out - the black helicopters are bringing copies of the International code!

WOOOOHOOO! I agree Yupster.

Patience waaaay beyond my own.

Martin, you are Job.

Malcolm, Brian, & Yupster, each of you are invited to join in if you have anything to say. Maybe one of you can comment on the issues Martin dodged. For instance, how much does the foam's R-value drop with aging? Or, is the great expense Martin bore to use both foam & fiberglass in his new home cost-effective? And since fiberglass loses half it's R-value in cold weather (Oakridge Laboratories study), why would a knowledgeable journalist use loser fiberglass to insulate his new home? Any thoughts? One of you must have a thought, maybe even two? If you find yourself struggling, team up and do it as a group project.

See, I just don't have the patience to even bother answering questions that have been covered many times here on GBA and could be answered with a few keystrokes in the search box. Or questions which come from a clear lack of comprehension as to what this article says. Which is why I commend Martin. But I'll do a group project with Malcom at the drop of a hat. I imagine I would learn a lot.

Yupster, I've read what you all pass off as "answers." I'm not too impressed. Do you have anything original to share? Parroting what "the experts" claim isn't advancing the discussion. It's merely sidestepping my original offer for you to make a contribution here. That offer is still on the table if you can contribute, please do. Your "group project" is here and now and you all seem stumped.

Larry,

LISTEN CLOSELY , as y0u like to put it. If you wanted a discussion about the relative merits of various types of insulation, you shouldn't have instead spent your time making insinuations about the honesty and motives of people like Martin and Joe Lstiburek. If you aren't being taken seriously, you brought it on yourself.

Edit: Larry has been here in the past, and the discussion he took part in devolved into much the same nonsense.

Malcolm, it was Martin who degraded and diverted the "discussion" from the topic to "insinuations," and his loyal followers who resort to personal attack further hijacking the topic into nothingness. I'm still waiting to read the experts speak. Where are they?

And you further delute the topic implying my past comments were incorrect. Please explain YOUR expertese enabling you to judge the correctness of my arguments. Is it based on "belief," "common sense," "everybody knows," or perhaps you have a Ph.D., in the Philosophy of Building Science?

unbelievable...

This whole exchange reminds me of something... oh yeah. Ever read an exchange between a science based rationalist and a flat-earth-conspiracy theorist?

Tyler, I understand your loyalty to Martin, but blind faith should be reserved for religious beliefs, not science. The arrogance here is thick. As with the others, you are welcome to add to the discussion if you have some knowledge to share. That's "knowledge," not opinion or loyalty pledges.

My only relevant knowledge at this point is a skill in critical thinking and recognizing gaslighting when I see it. You don't have to be wrong. Everyone can walk away with more knowledge.

I take what I like and leave what I don't. I'm actually personally more enamored by many assemblies that star cellulose than foam, but I won't close my ears when it comes to learning how and why foam can be used effectively.

Tyler, I've been warned by private email not to post here, seems the "regular posters" are upset. Still, I want my farewell without Martin deleting my account so I'll make this one last comment on the subject.

You say, "...but I won't close my eyes when it comes to learning how and why foam can be used effectively." That makes perfect sense, Tyler. We all owe ourselves and our families that simple philosophy. The perspective I've been offering is characterized in this simple analogy: Imagine going into a restaurant and ordering, "MEAT PLEASE." What would the waiter do/say? That's an ambiguous, even perplexing request, "meat?", The menu is full of dishes, most all contain, mostly feature, animal flesh. When the consumer asks for "meat", which meat does she mean? The Japanese are fond of highly marbled "Koby" beef, paying ridiculously high priced for a thin sliver. While Texans love their "Jacoby beef," raised on pasture grass. Others are content with a one-dollar burger from the local fast food joint. Between those extremes is a lot of territory and choices. It's all "meat!"

Likewise, when someone says they are insulating their home with "foam" what do they really mean? Each is formulated differently for different characteristics, some motivated by profit, others motivated to solve a particular problem with other foams. Some "foam jobs" are in reality, mostly fiberglass!

Just as we'd look silly ordering "meat" at a restaurant, ordering "foam" is as meaningless. A smart consumer must know which foam they are considering. That means identifying the manufacturer and obtaining at Material Data Safety Sheet, studies on shrinkage, off-gassing after installation, fire resistance, off-gassing during a fire, smoke developed, deterioration over time, loss of R-value with aging, is it a suspected or proven cancer risk, etc. Manufacturers are required to provide this information, salesmen don't. Once you choose which "meat" you want, you know exactly what you are paying for and the general results.

You see, there are dozens of foams and we won't look at all of them but looking at one and assuming it's characteristics and performance represents "foam" is self-defeating. You might as well sit down with the family in a five-star restaurant and tell the waiter, "I'll have a nice order of meat."

Adios, It's been a pleasure :)

Martin, your article, "Don't be dense...," is flawed. I did a similar test with different results. The difference is the setup. Your test is designed to fail. Let's skip the back and forth for now and later in the Spring I'd do the test again and document my procedure and the results. Maybe I missed something but it seems the author pulled a fast one...talking about cellulose then switching to fiberglass and then testing fiberglass and concluding dense pack didn't stop air infiltration. Even the frame is set up wrong. But actions speak louder than words, so I'll redo my study and provide you with full documentation and VIDEO!!!

Martin, your other "study" is perplexing. It reads, in part, "The TM project is supported by the TM consortium, a group of insulation manufacturers, and led by BSC." I don't see a list of the "insulation manufacturers" in the article. Do you know who the foam, fiberglass, and cellulose manufacturers were? Am I correct to assume all three industries were represented fairly?

Are they factoring in "thermal lag?" I think that's why they failed to detect any difference in the various material's R-value. Correct me if I'm wrong.

>"Dana, contact Oakridge Laboratories and ask for it. Or visit the CEMA site. They used to reference it in one of their articles."

In other words, you can't point me to one study from Oak Ridge National Labs showing that fiberglass loses performance at cold temperature.

In other words, I am not your gopher. Their research is government property. That means we all have access to it. Likewise, anyone can visit the CEMA site. If you cannot do your own google search, or contact Oakridge Laboratories, my experience is the CIMA contact is very helpful. Whatever you seek is available, just open your eyes and lift your fingers and do it. Or, if you choose, sustain your present beliefs. It doesn't affect me.

Oakridge Laboratories does genuine research. They are not dreaming up "research" so as to base a story or two on for profit.

There's money to be made leading the less motivated, like yourself, to the conclusion that benefits others. This country is full of bad "research," and lacks critical thinkers. You challenge the challenger. Maintaining the status quo doesn't benefit anyone except those circulating misinformation. They profit from closed, biased, minds. There's not much difference between "research", promotion, and advertising, in too many cases.

Good luck.

I've read dozens of insulation research studies from ORNL over the past 25-30 years, but nothing that remotely supports the notion that "...fiberglass loses half its R-value in cold weather." I'm just asking for the reference.

You are probably be referring to the 1990 document regarding ~half pound density open blown fiberglass and low density batts, which for decades has been everybody's straw man punching bag:

https://web.ornl.gov/sci/buildings/conf-archive/1992%20B5%20papers/048.pdf

With no top side air barrier in horizontal applications yes, the ultra-low density fiberglass is susceptible to performance degradation from convection currents. But (almost) nobody installs fiberglass that way any more, haven't for more than 15 years, and cathedralized ceilings without top side air barriers only use higher density fiberglass. Low density batts in vented cathedralized ceilings have a ventilation chute as a top side air barrier.

Agreed, fiberglass R value often increases down to about -20F.

Dana, fiberglass is blown in open attics every day. Open blowing is likely the most common use for loose fiberglass. I disagree, fiberglass was not "everybody's straw man punching bag." Fiberglass earned its poor reputation. Installers chose fiberglass because it's more profitable. They blended LOTS of air and under-blew routinely. For readers, not understanding, for example, if an attic requires 60 bags of fiberglass to achieve the contract R-value, The installer could install just 45 by mixing in extra air and fluffing the fiberglass to measure the full amount. Of course, it lacked thermal and settled, even more than it would otherwise.

The loss of thermal efficiency can be corrected somewhat by air sealing with plastic sheets (where practical) but the best remedy is a nice covering of cellulose insulation. I'm glad you found an article supporting the information I shared about fiberglass losing half it's R_value in colder weather. There are still many older homes needing to be retrofitted. And when homeowners see fiberglass in the attic they too-often automatically add more fiberglass short-changing themselves.

I agree, there are several costly techniques to doctor blown fiberglass so it's not so anemic. I prefer to skip all the hassle and start with a better product, a better technology. You see, fiberglass is a solid core material. It does.t really make sense as an insulator.I(f it weren't for the effectiveness of fiberglass lobbyists, each piece would still carry a cancer warning. (Good job lobbyists.)

You found the document ...I don't understand you dismissing it. :(

I'm not dismissing the document at all, but it's completely orthoganal to the discussion about dense packing & cathedralized ceilings, which can't be open-blown (with either fiberglass or cellulose) at the densities described in the 1990 paper.

At any density blown insulation in a cathedralized ceiling has both top & bottom side air barriers, and won't suffer the convective losses of ultra-low density open blown insulation with only a bottom side air barrier.

Cathederal ceilings have top side air barriers, whether vented or unvented, unless using purpose-made high density fiberglass or rock wool batts dense enough to limit convection. 1.8lbs fiberglass outperforms 3.5-4lbs cellulose inch-for-inch in an unvented cathedralized ceiling and is just as air retardent (or more), but neither are immune from moisture migration issues. While cellulose has substantially more moisture buffering capacity than fiberglass, that capacity is not infinite.

Fiberglass blowing wools for open-blown sold today do not get installed at 0.5 lbs density, and the glass is treated chemically to make it more opaque to infra-red, which is very different from the 1980s vintage stuff in that ORNL classic. That and several other studies of that era prompted the industry to correct most of the deficiencies. The chunky stuff such as AttiCat is basically shredded high density batt, and performs as well as cellulose in open blown installations without top side air barriers, unlike half pound batts or the low density fiberglass blowing wools of 30+ years ago.

Larry, the mere fact that you think that PhD is a meaningless, or perhaps even embarrassing title, is enough to dismiss you as a complete and utter f-wit. Everything about the way you argue paints you as a delusional nut. That is why you can't convince anyone, not because everyone here is blindly following Martin and GBA.

Trevor, I don't think "Ph.D., is "meaningless." I think too many Ph.D.'s do meaningless research! Most research in the USA is funded by the government and interested corporations. They get the results they want or the researcher loses funding. Our government changes "research" to appease corporations. The system is flawed. You can understand that, can't you? All I can do is give my view. You choose "what's "convincing" and what is not. Your choice reflects on your intellect, not mine. Do you have any strong views worth expressing (based on science, not emotions?)

I have to admit, "Ph.D., in Building Science Philosophy" sound hokey. Most degrees are "science" or "arts" and the study load reflects the quality of the degree. Each is different. We don't expect arts major to have the training of a science major. Engineering science is different from engineering art. I can't speculate where a philosophy major ranks. I wouldn't permit a "doctor of philosophy" to remove a hangnail. And I wouldn't hire an attorney with a philosophy degree. I wouldn't even let one work on my car. But that's just me.

PhD in Building Science Philosophy does sound hokey. Is that why you made it up? That isn't what Lstiburek has. It doesn't exist. You seem incapable and/or unwilling to grasp that having a doctorate of philosophy is not the same as a degree in philosophy. To even begin PhD study, you have to have a bachelor's degree in the field or a closely related field and preferably a masters degree as well.

I wouldn't hold a PhD against anyone from working on my car, as long as they were also a competent mechanic. To my knowledge, I don't think there's a PhD program for automobile repair (or even a BSc, for that matter).

Trevor, you again? You keep stating the obvious. Is it possible you don't understand so think I miss your "point"?

If someone is a certified auto mechanic then a philosophy degree is irrelevant.

Trevor, et al:

The best solution here is stop responding. . . just feeding oxygen to the smoldering conflagration.

Brian, good point..when you are chin deep in a hole it's long past time to stop digging. Trevor isn't clever. He's stalking on another thread, now. Since he hasn't anything to say perhaps he should give it a rest.

This ongoing discussion serves absolutely no constructive purpose.

I have an actual question that is on topic.

I'm in climate zone 6. The ceiling will be very much like the one in the article. I've already installed a vapor barrier on the sheathing under the roof decking using 6" of closed-cell foam. It's complicated to explain but trusses to correct a mistake result in almost 3 times the lumber that would normally be expected in typical roof trusses. This would suggest the thermal bridging is increased and the R-value of the system is reduced.

I'm considering netting the ceiling and blowing another layer of loose fill to increase the R value. My concern is this. How, if at all, should I control vapor on the warm side of the loose fill?

Poly would create a dreaded vapor trap between the closed-cell foam and the poly. Maybe a smart membrane? Or, maybe no added vapor barrier at all. It feels a little uncomfortable to allow the vapor to make it's way into the loose fill, and then stop it at the closed cell foam.

What's best here?

Thanks.

The interior side of the foam will be plenty warm - so it's OK that water vapor gets to it. But the lumber could see some moisture accumulation. So 1) air seal the interior side and 2) use a smart membrane.

Log in or become a member to post a comment.

Sign up Log in